U-Battery – Micronuclear power with intriguing business model

U-Battery was one of the more intriguing presenters at the Advanced Reactor Technical Summit (ARTSIII) held at the Oak Ridge National Laboratory last week. Even though this was a technical summit, the segments of the presentation that captured my attention were the business model and the funding source. However, certain technical choices are vital to support the business model and to attract the funding source.

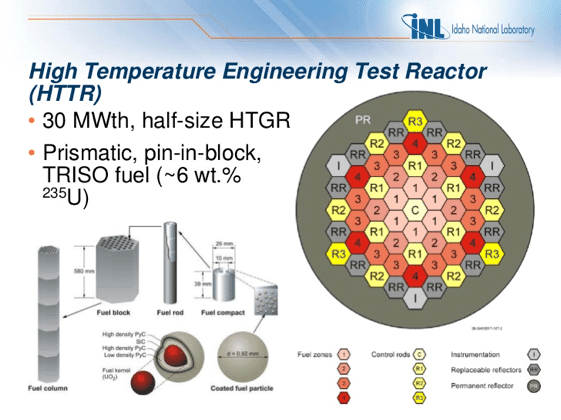

U-Battery is developing a micro nuclear reactor — a category of nuclear power reactors that produce less than 10 MWe — that uses a helium cooled high temperature reactor with hexagonal prismatic fuel elements similar to the ones used for the Ft. St. Vrain reactor. Like the FSV reactor, the key safety feature is a Triso coated fuel particle that has been proven to be able to retain fission products during indefinite periods of time at temperatures as high as 1800 ℃.

Though the below image is from an INL brief for a proposed system, the U-Battery fuel choice is virtually identical.

The reactor coolant system will have 40 bar helium circulated between through the reactor and a heat exchanger using a blower, but not one with water cooled bearings like the ones that helped to consign the FSV plant to an early demise. The secondary system is filled with nitrogen and runs through a fairly conventional turbomachine in a closed cycle cooled by low profile air-cooled cooling towers. The lack of water is both a system reliability consideration and a site flexibility feature.

The technical people who conceived the system initially considered using a thorium-based fuel cycle — which would still be an option for later iterations — but they realized it might make more sense to use uranium. That blinding flash of the obvious (BFO) happened when they learned that URENCO — which tells the world that they “… are committed to leading the way in uranium enrichment services for the civil nuclear industry” — was interested in their technology.

Though the final decisions have not been made, URENCO is backing current efforts and may decide to fund the detailed system development and licensing, participate in a partnership to build the first units and purchase them to supply power to its power-hungry facility at Capenhurst. This is a perfect nuclear version of the “eat your own dogfood” mantra well known in the tech industry.

Not only will Urenco obtain reliable, affordable, clean electricity that is a necessary ingredient to its continued success in its core business, but it will be demonstrating a technology that could result in a major demand increase for their core product offering of uranium enrichment service. With the right partnerships, Urenco could also expand into fuel fabrication. Since Urenco has energy-intensive manufacturing facilities in several countries, including the southwestern U.S., there is a terrific opportunity to achieve Nth-of-a-kind economies by meeting its own needs.

According to the presentation provided, URENCO’s current U.K.-based centrifuge plants require approximately 27 MWe. There are near-term plans to add another industrial operation (not a centrifuge) that will use another 3-4 MWe.

That means that the site could consume the output of approximately eight units of the 10 MWth variant. The building height is about 25-30 feet, the reactor, intermediate heat exchanger and turbine are all below grade.

Aside: If asked, I would counsel U-Battery to use a horizontally mounted turbine and generator arrangement vice the vertical one that their graphic illustrates. There is no value in trying to do something rare and difficult with the turbomachinery. End Aside.

Apparently, URENCO’s current site license for Capenhurst will need little, if any, modification to enable the company to build the U-Battery installations on its site. It is simply another facility upgrade as envisioned with the initial license application.

The presentation at the ARTSIII included a site map with several highlighted locations that have already been initially evaluated as suitable for the machines.

Assuming involved corporate boards decide to move forward, this project could leapfrog all other known advanced reactor developments. The partnership as described can tick almost every box needed to begin construction; they have funds, they have a design team, they have credibility, they have a site, and they have chosen a technology that has a sound basis of testing and demonstration.

The US DOE’s development of high temperature fuel manufacturing processes is complete; the fuel qualification testing program will finish crossing all of the t’s and dotting all of the i’s by 2023 with the current funding profile, but that might be dramatically accelerated with sufficient motivation and funding in the UK.

The U-Battery presenters mentioned my former employer, BWX Technologies as a potential fuel supplier. That is the company that has done the manufacturing process development and provided the Triso particles for the highly successful NGNP testing program.

Aside: If you visit the link in the above paragraph and look closely, you will note that the brochure is copyrighted in 2008. The company’s involvement in Triso fuel manufacturing is the real reason I decided to accept their employment offer after I retired from the Navy. Unfortunately, the high prices of natural gas in the 2004-2008 time frame had led the company to believe they needed to start their reentry into commercial nuclear energy with a reactor system using light water. They thought that would enable a faster market entry. End Aside.

Now that I have published this, I will start evaluating investment opportunities that can take advantage of the possibilities if they come to fruition. I’m a patient investor with a long time horizon and I do not provide specific advice related to securities purchases.

There is a good reason I keep going to conferences, workshops and summits related to nuclear energy development. Despite a pretty refined radar and a developed network of sources, I had somehow overlooked U-Battery. The first time I had heard of the company was when I read through the agenda for the ARTSIII event. If I had not been busy in a family way when I saw that agenda, I probably would have done a bit of searching, but I decided to wait to hear what the company reps had to say. The maturity of the project took me by surprise.

There are an increasing number of reasons to get excited about advanced nuclear technologies, even if the basic ideas were proposed and developed decades ago. Since deployment never occurred, the old can look new, improved and exciting to the energy market.

I have following this development since I noticed the role of scientists at my alma mater in the development of this design in 2011. I took an interest because I was inspired by Rod’s Adams Engine, which is a very similar but importantly different concept. I like this design and I have been urging my colleagues to take an interest, because I see many applications for our larger clients, which include hospitals, datacenters and airports. I like Rod’s design better though because it is likely to be significantly more economical. I hope to gain permission soon to seriously pursue this development within my company and my proposal to the U-battery consortium would be to consider taking on board the economical ideas from Rod’s design. I have been lobbying for this permission for years but this year could be a breakthrough year!

How beneficial to efficiency is a recuperator and is it much of a capital/maintenance cost? Rod, I know you want to forego a recuperator in the first Adams Engine models in order to maximize simplicity and capital cost.

Referring to the white paper on the U-Battery, how practical is turning the “pre-cooler” into a waste heat recovery boiler? I’m trying to ball park if it will be possible to push out the “60% club” gas turbines.

The specs at the web site somewhat differ from the graphic: Twin 10MWt, 4MWe, Helium/nitrogen-cooled, TRISO fuel, 800˚C http://tinyurl.com/gt5zjyt

@Benjamin Haas

My opinion on recuperators hasn’t budged. They add cost and complexity that has insufficient return when fuel is cheap.

If you’re referring to the graphic includ d in the post, please notice that’s not the same system. It simply has a similar fuel type.

Thanks Rod as always! It’s good to see more designs coming out and potentially very close to first build. I’m a fan of the ‘energy battery’ or ‘heat battery’ metaphor for the new designs.It’s great to see them in multiple sizes as well, which enables a lot more applications.

I love to read about (and do my best to understand) the technology and design of the reactors, but it’s time to get past that in conversations with the public. An ‘energy battery’ that can plug in to many kinds of applications for industrial heat – chemical manufacture, steam generation, electric power generation – is something that could be rolled out widely.

I’d like to have a lot of industries looking at how to replace existing fossil fuel furnaces, boilers and other heat sources with nuclear heat batteries. Jim Holm used to have a coal2nuclear web site which was premised on replacing the boilers in the biggest fossil fuel burning electric generation stations with nuclear heated steam generators. Reactors providing around 650 to 700 Celsius would directly replace the big boilers, and the coal yards at the plants would provide the sites needed.

Sadly, he kept changing the site, and now puts everything under skyscrubber.com. The coal2nuclear ideas and information are still there. IMO the best place to start on the site is the Skyscrubber sitemap.

His well-researched claim is that fewer than 2% of all coal power plants (about 1200 in total) are responsible for about 80% of CO2 emissions from coal burning. Fixing the big ones first to tackle CO2 emissions reduction, and preserving the existing infrastructure, sites, permits, and jobs is IMO a good strategy to adopt.

Firstly the fuel. A standardized 29% LEU could be combined with requisite amount of thorium for any type of reactor. A much higher amount of thorium will be irradiated and burnt in situ, resulting in more energy from same amount of fissile fuel.

Secondly the coolant. Argon is equally chemically inert but much cheaper. As a coolant, the neutrons it consumes are insignificant.

CO2 could also be used if there are no chemical problems. It may depend on temperatures of operation.

So here is a vacant lot a few blocks away from my house:

https://www.google.com/maps/@43.5663895,-116.5625758,129m/data=!3m1!1e3

Sounds like one of these would squeeze in juuussst perfect right there.

I know that this reactor is supposed to be air cooled, which is not a bad idea in general, but if they were to put one of them in around here it would be just about a perfect situation to put in some district heating lines while we were at it and put the waste heat to use.

Nice and toasty in the winter, all the hot water you want, run adsorption chillers for A/C in the summer. No need to turn the thermostat up/down! Plenty more where that came from!

Delightful.

As long as I’m dreaming in technicolor here then while the road is ripped up putting in the district heating pipes they might as well finally get fiber optic lines into all the houses as well. Co-locate the network equipment in the same building as the plant, nice little side business and it would be physically safe in a good sturdy concrete building like that. Have our own little local micro-ISP, we could call it AtomWeb or something.

Mmmm, I like it already.

When we talk about ‘Fission is the new fire’ I’d love to see the world go whole-hog with the idea, what else could we do if a nuclear plant is ‘just’ another nondescript industrial building with a couple of coolers on the side of it?

Here’s another idea:

https://www.google.com/maps/@43.6086009,-116.3131369,259m/data=!3m1!1e3

That building there use to be an Eddy’s Bread bakery, it’s been more or less vacant the last few years with a string of short lives businesses renting out the little office on the side of it.

Lets say we get another commercial bakery in there of some sort, and we have one of these mini-reactors either co-located on site or very close by.

Why not use some of the reactors heat to melt a loop of solar salt or something like it, then you could pipe the salt into the bakery and use it to bake the bread? Like the ovens would have a radiator grid for the salt to flow through rather than electric heating elements or gas burners.

Oh, and of course while we’re at it close-to-free space heating for the building and snow melting/deicing in the parking lot.

Lets go a step even further, pan just a touch south on that same map and you’ll find a farm field:

https://www.google.com/maps/@43.6059344,-116.310224,517m/data=!3m1!1e3

Every year it seems like all they grow is corn and corn alone, maybe they’d be interested in a new business opportunity?

See I’m thinking greenhouses, which are traditionally expensive to heat but should be a lot more reasonable with the waste heat of a nuclear plant next door. What should they grow? Well you could do hydroponic vegetables and the like Which Would Be Fine, getting an extra harvest or two per year would probably make it worth it alone, but I have another idea.

See there’s nothing stopping you from keeping these hypothetical greenhouses at tropical conservatory temperatures even in the depth of winter, so I’m thinking bananas.

Hear me out! Right now the banana you’ll find in the grocery stores is a variety called the Cavendish which didn’t use to always be the case, the variety that was cultivated back in the day was the Gros Michel. Cultivation switched from the Gros Michel to the Cavendish because a fungal infection called Panama Disease essentially wiped it out forcing the switch to a variety that is resistant. (This is why ‘banana’ flavored candy tastes kind of banana-ey but different, the flavoring is based on the Gros Mitchel and not the Cavendish.)

But you know what? This is Idaho, there aren’t any bananas growing within a thousand miles or more of here. This very isolation means you could grow the Gros Michel banana here in this greenhouse without fear of a tropical fungal disease wiping them out.

Unique crop, check.

Appeal to the ‘locally grown’ crowd, check.

Higher value than a commodity like corn, check.

I like this idea also.

This.

This is how integrated I’d like to see nuclear power in our society.

@Jagdish

I think you are missing the point about the choice of fuel cycle here. The developing company wants affordable and clean energy for its own use, but it is also strongly interested in developing larger markets for its uranium enrichment services. It’s not worth much effort to these developers to seek to maximize the amount of energy produced per unit of fissile fuel.

The paper I linked to indicates that CO2 was initially considered, but abandoned when developers learned more about the chemical reactions that would take place between the coolant and the core materials at the temperatures they seek to employ.

How cheap would Argon be if there was a dramatic increase in the demand caused by building hundreds to thousands of these machines?

I remain intrigued by a simpler system that gets rid of most of the proposed heat exchangers and substitutes cheap and virtually unlimited stable, mostly inert nitrogen gas as a combined coolant and working fluid. I’d also lower the operating pressure to something approaching the pressures seen in combustion turbines.

Finally, for the sake of flexibility and ease of mass production manufacturing techniques, I’d use pebbles instead of prismatic fuel elements.

With those minor changes, the U-Battery would closely resemble an Adams Engine. 🙂

@Nick P

May I promote your visions to the front page? They might encourage more dreams — which are eminently achievable, by the way — from there.

I like the way you think.

Argon is about 0.93% of air, and I suspect that any large increase in demand would ultimately result in lower prices because of economies of scale.

Note we’re talking about a melt proof core design here (aren’t we?). Which requires no regulation beyond “shine radiation” protection, like a high powered radiography source, or a medical radiation source. So I don’t understand the resistance (by some) to my melt proof core idea suggestion for all future designs, as I have seen in other discussions here. As Nick P points out “dreaming in technicolor” is required.

When nuclear reactor cores, making heat and electricity are melt proof, only then will they be in home utility rooms, industrial machinery rooms, and even the power plant for Disney World. When the only argument against it is “but that lets the antis win their argument” all I can is “duh?”.

If this kind of technology is do-able today, and apparently it is, I say the mindsets by pro-nukes are the barrier, not the antis.

@mjd

I like melt proof cores and plan to use them if I ever get back into the reactor design and development business.

However, I also like the triple option offense as implemented by Paul Johnson and Ken Niamatalolo for the Naval Academy football team.

In neither case would I seek to require that everyone else make the same choices as I have. Situations may vary. There is an economy of scale that encourages the development of some large power plants, as long as they can be built in ways that avoid the diseconomy of scale. It is virtually impossible to produce a melt-proof reactor that produces thousands of thermal megawatts.

You may be right, but argon also has the disadvantage in operating situations of fairly significant cross-section for neutron absorption. Though that cross section is about 1/3 as large as nitrogen’s, there is a real difference in the decay of the resulting isotope.

C-14, the product that comes with an (n,p) reaction in N-14 is a mildly radioactive substance that slowly decays with a nearly pure, low energy beta emission. The half life is 5,700 years

Ar-41, the product that results from a neutron absorption in Ar-40, is a highly radioactive substance that rapidly decays with a combined beta-gamma decay scheme. 99% of the decays include the emission of a penetrating 1.3 Mev gamma. An Ar-41 cooled reactor would need substantial shielding for all systems that contain Argon that has recently passed through an operating reactor.

I’d also suggest that any maintenance exposing workers to unshielded coolant be delayed for about 10-24 hours after shutdown to allow the gamma source to decay away.

I’m not saying that one cannot use argon as a coolant. I am saying that there are engineering tradeoffs that need to be evaluated and addressed. I’ve been through this decision process. When I did it, the best answer was low pressure nitrogen; other results may vary depending on the decision parameters.

I have hope for you…. you’re dreaming in soft pastels… but are 1000s of MWt a different problem/discussion than reactor core type? Like maybe a dispatch-able grid thing? Too many nuances spoil the broth, I’ll opt for an un-meltable core in my utility room and, unlike home solar, un-hook from the grid. And no, I don’t want to sell anything back at my convenience. I also think a lot of industrial users would prefer that also.

But a different question… do you agree regulation should then be about like “shine” sources, or is there still another fake “proliferation and waste” issue here? It’s hard to select a path when their are hidden obstructions. But for now I’m with Yogi, “When you come to a fork in the road… take it.”

I also try to maintain a wide color gamut.

The flip side of Ar-41 is that it will reach a stable concentration after a few hours of operation, unlike C-14. The 109-minute half-life means it presents no disposal problem either; after a couple of days you could simply vent it if you wanted to.

An integral steam supply system wouldn’t have anything that needed prompt service, and the reactor core would probably need to cool for quite some time before you could get in to work on anything close to it. As a cheap and widely-available alternative to helium coolant, argon looks good to me. As a working fluid suitable for commodity turbomachinery, I can see the attractions of nitrogen. I’m still rooting for lead coolant, though.

Of course.

Nick –

I’d love to eat some Gros Michel bananas, but there are some obvious alternative crops that would generate way more cash flow per square foot of greenhouse. Sure, it might not be legal yet in Idaho, but it would be fine in Washington or Colorado.