X-Energy introduced its company and first product to Virginia chapter of ANS

On Tuesday, October 27, three leaders from X-Energy spoke to the Virginia ANS chapter about their company and the Xe-100, the high temperature, pebble bed gas reactor power system that they are designing.

During the presentation, meeting attendees learned that X-Energy is an early phase start-up with a total staff of a few dozen people, most of whom share one of three backgrounds. Some are former NASA engineering contractors, some come from the U.S. DOE’s Next Generation Reactor Program (NGNP) and some come from South Africa’s Pebble Bed Modular Reactor (PBMR) program.

The founder, CEO and primary funding source is Dr. Kam Ghaffarian, who cofounded Stinger Ghaffarian Technologies (SGT) Inc. in his basement in December 1994. He’s now the sole owner of that company, having bought out his cofounder about seven years ago. SGT is one of the largest engineering services contractors for NASA, with an annual revenue of $400 million and a backlog in excess of $3 billion.

Here is his explanation for founding X-Energy:

I began X-energy because the world needs energy solutions that are clean, safe, secure, and affordable. With so much at stake, we cannot continue down the same path.

Dr. Pete Pappano provided most of the technical portion of the talk. He described himself as a “graphite guy” who has worked for SGL Group (The Carbon Company) and at Oak Ridge National Laboratory in the group that produced the fuel compacts used for performing qualification irradiations for the highly successful TRISO fuel that has been manufactured on a testing scale for the NGNP.

Meeting attendees could feel his passion for his favorite material as he provided a synopsis of the reactor grade graphite production process; even though that was peripheral to the X-Energy talk, it was fascinating information.

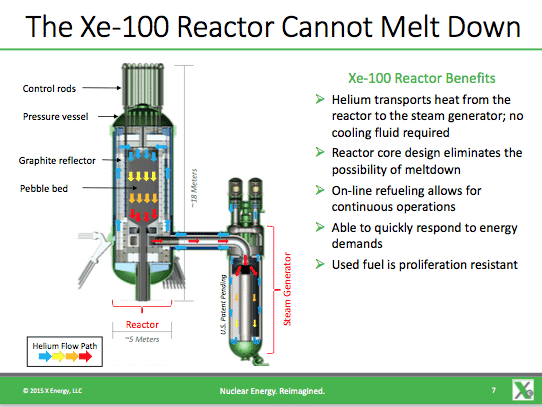

Pappano provided an overview of the Xe-100 which is a 125 MWth helium-cooled, graphite-moderated, once-through-then-out, passively-safe, pebble-bed reactor. The helium is pumped through the reactor and then through a steam generator that produces superheated steam sent to a standard Siemens steam turbine to produce 50 MW of electric power.

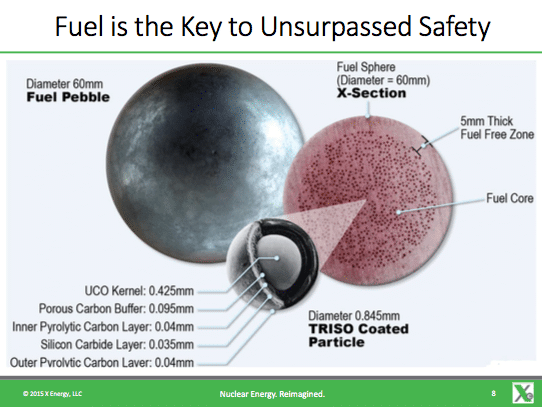

Each reactor contains about 170,000 pebbles. The pebbles are 60 mm in diameter with 5 mm thick unfueled layer of graphite on the outer part of the pebble. Inside the unfueled shell, there is a mix of about 25,000 tiny particles with a graphite binder. The particles are less than a mm in diameter; the fuel kernel in the center is about 475 microns in diameter. It is surrounded by four layers; a porous layer of pyrolytic graphite, a dense layer of pyrolytic graphite, a layer of silicon carbide and a final layer of dense pyrolytic graphite.

Each pebble contains about 9 grams of heavy metal enriched to about 10% fissile concentration. TRISO particles have been tested with various combinations of uranium, thorium and plutonium. X-Energy is aiming to initially use enriched uranium in the form of UCO.

Even in the case when all coolant stops flowing and coolant pressure falls to atmospheric, the reactor system cannot overheat because there is sufficient heat transfer through conduction to the surrounding environment to keep the hottest places inside the reactor below 1600 C. The TRISO fuel tested for NGNP has been shown to be able to maintain its integrity even when heated to 1800 C for lengthy periods of time.

The graphite reflector that surrounds the pebble bed container is designed to last for the life of the system. X-Energy currently envisions that the reactor will never need to be shut down because new fuel can be continuously added while depleted fuel is dropped out of the bottom into a container.

The proposed installation calls for four reactor/steam generator systems with a single used fuel storage vault in the center of the associated silos. That vault will be sized to hold a lifetime of used fuel. There will be an automated system that moves filled containers from below the reactors and replaces those containers with empty ones as needed. The containers will be moved into the central storage vault.

X-Energy has not yet begun its interaction with the U.S. Nuclear Regulatory Commission. Ralph Loretta, the Chief Financial Officer, explained that the company would like to be further along in its design process before it begins paying NRC professional staff-hour fees.

Following the meeting, I spent some time talking to the X-Energy executives and exchanging business cards. I’m in contact with X-Energy’s public relations office and will be arranging a discussion for the Atomic Show sometime in the near future. Feel free to pose questions here; I might use them during that interview.

Being as how I am 64 years old, will I still be alive when one of these reactors is put to use? I don’t see anything in your posting that gives a timeline.

And how much of the development/construction time is spent jumping through regulatory hoops as opposed to actual construction?

@poa

There’s no timeline yet. Too many unknowns in terms of regulation, finance, and marketing.

No technical show stoppers or new inventions required.

Preventing a bog down at NRC will require technical skill and political expertise.

Also….forgot to include…..

How big is this reactor system? Control room, Infrastructure, reactor, etc? Footprint??

@poa

You can find answers here ANS_X-energy Presentation_PUBLIC_10-28-15

Do you have any information about how efficiently this technology will use the Actinides in the fuel?

With 10% enrichment, fuel will exit reactor after producing an average of 85,000 MW-days/ton of heavy metal.

Rod, I assume that you have a residual fondness for gas cooled Pebble Bed Reactors, but Professor Per Peterson, has a molten Salt cooled Peffle bed design the Mark One, that is out of the preconceptual phase. That is it is ready for blue printing. I suspect that the UCB could be talked into licenesing the designfor a reasonable price. Molten salt cooling leads to much smaller core size, hence less material and smaller labor costs.

I thought that the South African attempt had issues with shuffling/moving the pebbles in/out of the core? And the Germans did as well?? How/why does X-Energy believe their design is different or avoids this issue???

What is the highest outlet temperature?

If above 700C, what materials or tricks are used to get to higher temperatures?

Are there any processes that could be uniquely done at your highest temperature? Like making hydrogen from water?

Egads. I hope Rod, or someone, answers my dumb questions first, before we get to the Twilight Zone, (at least to me and my buddy John Q), part of the discussion.

What makes the used fuel from XE-100 proliferation resistant? I would think one could dissolve the pebbles and extract plutonium.

I was looking at it from the opposite side – just how difficult is it to recycle 10% enriched UCO TRISO fuel?

I found answers (and much more) here, especially Section 14:

http://www-pub.iaea.org/MTCD/publications/PDF/TE_1645_CD/PDF/TECDOC_1645.pdf

@Atomicrabbit

X-Energy is currently planning to store a lifetime of used fuel on site in an underground silo. No discussion of recycling.

Apparently Savannah River Site has developed a process to chemically digest the pebble graphite without producing fines, and intends to process the HTGR reactor fuel from the two shutdown experimental reactors in Germany, and thereby also repatriate the US-origin HEU kernels. Of course, the local “environmentalists” are opposed:

https://www.inmm.org/AM/Template.cfm?Section=30th_INMM_Spent_Fuel_Seminar&Template=/CM/ContentDisplay.cfm&ContentID=5192

This fuel is UO2 and ThOs, not UCO, but the important development is the graphite digestion process. I’m not sure how they are also stripping the SiC layer. Once down to the fuel kernel it can be recycled like any other U/Pu/Th mixture.

@Susanne Vandenbosch

Proliferation resistance is a fair question question. I’m no expert, but there are at least three issues:

1. Who is doing the proliferating? Is this a rogue state who has bought a commercial reactor and hijacked it for nefarious purposes? Or is it a rogue terrorist who has overcome plant security, the National Guard, the U.S. Army, Rainbow Six, Chuck Norris, and intense gamma radiation long enough to collect used fuel from the storage silo, load it into a shielded truck, and spirit it off to Auric Goldfarb’s super-secret laboratory in the Bahamas where not only does he have to fight off 007 and MI-6, but also confronts

2. Fuel residence time. Oh. This was a commercially run reactor, wherein all of the pebbles cheerfully cooked away for two years before being drained. Darn. Can I go back to step 1, go back in time, and start at initial fuel-up so that I can drain the reactor bed and hijack the pebbles before they’ve been irradiated longer than about 60 days? Otherwise this stuff is totally unsuited for my intended purpose. Can I have a do-over? Holding off plant security, the National Guard, the U.S. Army, Rainbow Six, and Chuck Norris for six or eight weeks should be a piece of cake.

The problem here is isotopic purity. In a nuclear reactor fertile U-238 breeds fissile Pu-239 which works great in reactors and also can make for an atom bomb except for one thing: Pu-239 doesn’t stay Pu-239 in a reactor, at least not all of it. Some goes on to absorb another neutron to become Pu-240, which is still good for reactor fuel, but really problematic for building bombs: the Big Boys try to limit their Pu-240/Pu-239 ratios to less than 6%, hence the short reactor residence time requirement.

The problem the Big Boy Bomb Builders have with Pu-240 is that Pu-240 undergoes spontaneous fission at random times with corresponding random neutron release. Not often enough to affect reactor operation, but often enough to disrupt the micro-second timing required to assemble a critical mass in a bomb. The result is a premature detonation strong enough to blow the device apart before much mass is assembled, but usually not much else. In this context usually is a closely guarded state secret. What is known is the requirement to develop and test (think trinity) an elaborate implosion device rather than a simple gun bomb (Hiroshima), even with 6% weapons-grade plutonium. But here we don’t even have that, yet.

3. Dissolve or grind TRISO pebbles to dust. Then extract the heavy metals via concentrated nitric-acid / organic solvent fractionation, followed by equally messy PUREX process to isolate the plutonium, of whatever isotopic purity.

4. All this used-fuel stuff is intensely radioactive. All the extractions and purifications in step 3 must be done remotely.

Which is of course possible and has been done — but only as concerted state efforts. If its a state effort, the state has more control over the reactor, but less control over IAEA inspectors, who are alert to this sort of thing. Weapons proliferation is a serious issue, at the state level. All Gen-IV reactors are required to be at least as proliferation-resistant as today’s light-water reactors, and Xe-100 is no exception. The above is just the highest overview of the general problems faced by a would-be plutonium bomb builder, additional safeguards built into any particular new reactor design are usually shared by the reactor vendor only with the state building one, and with the IAEA.

Tom Clancy once wrote a book illustrating how a terrorist organization might build a crude bomb after first stealing weapons-grade uranium or plutonium. Today’s trend is to avoid production of weapons-grade uranium and plutonium in the first place. Commercial PUREX plutonium refinement is being abandoned in favor either of once-through fuel cycles that don’t separate uranium and plutonium from the highly radioactive fission products or higher trans-uranics, or fully-closed fast reactor fuel cycles that remove the fission products, but again don’t separate plutonium from the radioactive higher trans-uranics.

Any state who really wants to build an atom bomb may still do so, either via plutonium production in a dedicated short-residence reactor and remote PUREX refinement, or via uranium enrichment to weapons-grade levels (HEU, typically greater than 90% U-235). Both routes require time, energy, and large industrial infrastructure. Neither can go undetected. It is then for the Rest of the World to decide what, if anything, to do about it.

Another technical issue (sorry poa, but I can’t resist) is the helium circulator. I’d like to know more about that. The thing that killed Ft. St. Vrain was the water-bearings feature of the helium circulator. You can avoid that with magnetic bearings but then how to do keep the helium in? Helium gets through very small spaces and I’m not sure how you solve that problem unless you use a liquid seal, and then you have infiltration issues.

@Wayne SW

I would too. But I note with interest Curtis-Wright’s recent qualification of their AP-1000 canned-motor cooling pump. I don’t know what route X-Energy has taken, but I’m thinking along the lines of canned-motor with fluid (gas) or magnetic bearings. Maybe we could ask them, or check with USPTO…

Magnetic bearings would leave a gap that would have to be sealed with something. Helium is just so mobile that even the smallest gap or other opening means exfiltration of helium. Water was used at Fort St. Vrain for this reason, and it created another problem, water infiltration. If you’re thinking of “canning” the entire circulator then you still have to deal with water exfiltration issues, if you go with that as a liquid seal. The “can” just fills up with leaking water. FSV had a water filtration and recovery system but it never worked right, and part of the problem was that no one had experience with a helium circulator that big (in a nuclear application anyway).

In other words, either magnetic or gas bearings would be just fine in a canned pump.

This may end up varying quite a lot from stock as magnets don’t do well with high heat and unless somehow isolated may suffer degradation.

What loss rate are we talking about here? Last time I looked, helium is about $30/kg, or $2.5/cu.m, according to the USGS. Can there not be a pressurized helium supply tank?

I saw the “Xe-100” label and I thought that it might employ a blend of Helium and Xenon as the coolant.

There have been studies on this sort of blend, and it could be a promising approach to an Adams Engine. Just get the blend to equal the weight of air and it would work fine in an existing gas turbine, right? Sure, it would cost more than Nitrogen, but you would avoid formation of Carbon-14 and the coolant would be absolutely inert.

Here is a citation to one such study:

Mohamed S. El-Genk and Jean-Michel Tournier. “Noble-Gas Binary Mixtures for Closed-Brayton-Cycle Space Reactor Power Systems”, Journal of Propulsion and Power, Vol. 23, No. 4 (2007), pp. 863-873.

South Africa almost went bankrupt trying to get a workable Pebble Bed Reactor.

Here’s a good start:

http://www.southafrica.info/news/pbmr-mothballed.htm

@Paul

There are lessons worth learning from PBMR project. Most of the problems were related to heat conversion system, not the reactor.

The participants at X-Energy are well versed in what worked and what didn’t.

Ok….so now I’m confused. (Gee, who coulda imagined?)

Whats the skinny here? Is this reactor design an experiment to see if such a design is feasable? Or is it being developed and built to be put to use on an existing power grid? There seems to be some disagreement here whether or not the design is workable. I assumed that it was being built as a working reactor, with a buyer, and a destination. But really, its just s big ‘ol lab rat?

Please Poa, that’s big ‘ol radioactive lab rat. Keep track of the date, will ya?

DOE thinks the design is workable. Of 6 advanced designs considered last year, two were considered “mature”: S-PRISM and Xe-100. In each case its a matter of building — and licensing — the first one. Probably as a “research reactor connected to the grid” since they would be foak of “new” technology. (There’s nothing really new about either, as their respective vendors take pains to stress.)

If the pebble graphite is difficult to dissolve it could probably be crushed and the plutonium extracted from the crushed pebbles. I am skeptical about the alleged proliferation resistance of the XE-100 reactor. .

Graphite is not the barrier. The real barrier is the SiC coating around each particle of fuel.

Not really too hard to break that, though. Because it is a nuclear fuel, it will heat up if exposed to a neutron flux. If that heat is not removed, the fuel will melt — even the SiC coating. Thus, a simple subcritical reactor could ready the fuel for reprocessing (the reactor would, of course, have to have a system for removing volatile portions of the spent fuel.

It’s not that easy.

The SiC layer is very robust. The 1600 deg. C number given above in the article is the temperature at which the TRISO fuel only begins to fail. Of the billions of particles in the reactor, a small portion of the less perfectly manufactured ones fail, usually by internal pressures causing the SiC layer to crack. Even then the actinides are not a concern — they mostly remain in the kernel inside the cracked SiC shell. The real concern is escape of the more mobile fission products.

To get a significant portion of the particles to fail requires much higher temperatures — well above 2000 deg. F. Even then, getting the kernel out of the SiC is a challenge.

If I remember correctly, the reprocessing techniques that were developed in the 1960’s and 1970’s called for burning off the graphite to get at the particles. (This itself is not trivial, since nuclear-grade graphite does not combust easily. This process would need to be done in an oxygen-rich environment.) Then the particles are mechanically crushed to get at the kernel. This assumes that you can get your hands on enough material (which is mostly just bulky graphite) to make the process worthwhile.

This is a lot of effort to get at some plutonium with a poor isotopic composition for bomb making. At this point, it would probably make more sense just to build a production reactor and make your own plutonium.

Your memory about the contemplated reprocessing methods is also my understanding and I understand that graphite would be pretty much impervious to the ultra high temperatures from a coolant-free reactor.

While SiC is very robust, it was not formed in Mordor’s Mount Doom. The temperatures you cite are certainly high, but consider that “The temperature of corium can be as high as 2400 °C in the first hours after the meltdown, potentially reaching over 2800 °C.” Admittedly, that is a quote from Wikipedia.

As for the bigger issue of nonproliferation and nuclear energy: I’m aware of all of the arguments about how bombs are not inherently associated with using fission for peaceful energy applications, but I am also convinced that, because fissile isotopes are common to both uses, that there should be a “double standard” (or maybe even a “triple standard”) for “proliferation resistance” in different countries. My best example: so WHAT if a reactor design is horrifically “proliferation prone” if it is a reactor in the United States that meets the oversight of the NRC? It isn’t as if the government is going to make more A-bombs or sell fissile material to a rogue nation, is it? And with NRC oversight, the possibility of some rich “Bond Villain” type diverting material for nefarious purposes is averted.

X-Energy currently envisions that the reactor will never need to be shut down because new fuel can be continuously added while depleted fuel is dropped out of the bottom into a container.

Like all previous pebble bed designs, the pebbles are added at the top and removed from the bottom. I am wondering if it would not be easier to avoid the pebbles getting stuck (a perpetual problem in previous designs) by pushing them in from the bottom and removing them from the top.

@RRMeyer

Stuck pebbles have not been an issue in previous designs. There have been a few challenges associated with the system that removed pebbles, inspected them, and returned them to the reactor. In designs like the HTR-10 and the German AVR, the pebbles make between 6-8 passes through the reactor before they are considered to be depleted.

The Xe-100 concept involves far slower traversing of the reactor and a one time removal after the fuel has been depleted over an approximately 3 year period.

There is no system that attempts to move pebbles back to the top of the core.

This also addresses Susanne’s question about proliferatin resistance – by the time the fuel has spent three years in the core, it will be a complex mixture of isotopes that is more difficult to separate into fissile and fertile streams than natural mined uranium.

There will always be some who claim it can be used to make a bomb, but it is so unlikely as to be an acceptable design.

If you want to remove the pebbles from the top, then replace the helium coolant with molten salt. Then the pebbles will float and you can skim them off the top. This is the concept that UC Berkeley has been working on, which Charles Barton mentions above.

I liked the site with the picture of the dirt road leading off into the distance through a beautiful green field. It tells me natural, simple, clean and the road less traveled.

“The helium is pumped through the reactor and then through a steam generator that produces superheated steam sent to a standard Siemens steam turbine to produce 50 MW of electric power.” Pumped? I would think the Helium would still be a gas and “blown” would be applicable. I didn’t see a reference to what kind of pressure this thing will operate at. Intuitively, I would think you would have low pressure and high temperature. Unless, the Helium needs a higher pressure for better thermal conductivity.

I noted that on their site they stated:

Confirmed the technical and economic feasibility of using the Xe 100 to expand an

existing coal fired station.

Would this be a separate unit or would they use the high temperatures to aid in super heated steam and maybe an extra turbine up front of the lower temperature / pressure steam?

The interview with these guys will be an interesting conversation.

The helium is driven by a component called a “circulator” or, more informally, a “blower.” It’s not a pump in the same way that today’s light water reactors use pumps.

These designs typically operate at pressures of 5 to 7 MPa.

“The helium is driven by a component called a “circulator” or, more informally, a “blower.””

Good – More like a conventional ID fan or FD fan. Well established technology. This will be blown about at about 1000 lbs per square inch (7MPa) relative to atmosphere. (Sorry, I don’t deal with Pascal pressure units very much.)

Maybe this one has a chance. Per the following link, the fuel will be available:

http://www.world-nuclear.org/info/Nuclear-Fuel-Cycle/Conversion-Enrichment-and-Fabrication/Fuel-Fabrication/

From the link:

“The main HTR fuel fabrication plant is at Baotou in China, the Northern Branch of China Nuclear Fuel Element Co Ltd. From 2015 this will make 300,000 fuel pebbles per year for the HTR-PM under construction at Shidaowan. Previous production has been on a small scale in Germany. In the USA, Babcock & Wilcox is making TRISO fuel on an engineering scale, funded by the DOE which is aiming to take it to commercial scale.”

I just re-read the Wikepedia description on the Fort St Vrain plant. The circulator fan was a big problem due to water cooled bearings. Smart designers would not want history to repeat itself as the article essentially states. All the stated problems looked like they had fixes.

http://www.world-nuclear.org/info/Nuclear-Fuel-Cycle/Conversion-Enrichment-and-Fabrication/Fuel-Fabrication/

Even Mr. Adams had a mention in this one.

There’s a LOT of info on pebble bed reactors on the Ars Technica thread: http://arstechnica.com/civis/viewtopic.php?f=26&t=104024

To summarise (according to that site:)

Most of the background work for the pebble bed reactor was done by Germany, who had the AVR research reactor from which the Triso fuel particle was developed. Germany then made a prototype commercial reactor, the THTR, which was a “politically forced disaster.” Learning a lot of hard lessons, they developed the HTR-Modul, a much more conservative and simplified design. The HTR-Modul was fully licensed and accepted around 1988 but by then Chernobyl had happened and it was politically impossible to build. Instead Germany sold the whole thing to South Africa.

South Africa took the concept and tried to develop it into their PBMR, reportedly abandoning any type of Keep It Simple Stupid philosophy. The Chinese by contrast actually designed and built a small research reactor even more conservative than the HTR-Modul, and on the basis of this are now constructing prototype commercial reactor – the HTP-PM. The reactors are small in size and use helium-to-steam heat exchangers to run steam turbines, and they will probably be up and running before 2020 (2017 was the original start date.)

Whether X-Energy actually have something or they are trying to catch a ship that has both sailed AND arrived is a matter of opinion. The interesting thing about fuel pebbles is that all the fancy tech is in the pebbles themselves. Once a supply is available it opens the floodgates to all sorts of designs. The big question is whether the Chinese will corner the market.

>The graphite reflector that surrounds the pebble bed container is designed to last for the life of the system

More accurately: the life of the system is limited by the non-replaceable graphite reflector.

Curious to see that they’ve gone for such a small core when HTR-PM (and HTR-Modul) can apparently achieve the same passive safety with a single-zone core of double the power output. It would be exceedingly odd economic logic if they’d sacrificed power density to achieve some targeted reflector lifetime for example, although I suppose that’s possible.

Hey Rod, I have a question I hope you find interesting enough to ask of X-Energy whenever you have an Atomic Show conversation with them:

What factors led to the design choice to use a steam turbine as opposed to a closed cycle gas turbine? I’m not an engineer, so forgive me if if this a erroneous or inadequate characterization, but my understanding is that the Brayton cycle is generally superior to the Rankine cycle in terms of flexibility in operations, thermal efficiency, capital cost, and plant footprint. The only limit to using a gas turbine is whether one has an adequately hot heat source, which high temperature gas-cooled reactors are generally known to provide. Obviously, there’s something here that I’m missing so further elaboration on this design choice would be appreciated.

Thanks.

If I remember correctly one of the X-Energy slides had the reactor at a former coal plant site. There have been several SMR concepts where the reactor would just replace the coal furnace and use the existing steam side to re-use the steam turbine/generator set and the existing switchyard if the reactor can produce the same superheated steam as the coal plant. Thus, the “efficiency” is not in the “thermal” part but in the “infrastructure” part.

Enjoy!

Flying Finn

@Flying Finn

The concept of replacing the coal furnace and making use of the rest of an existing plant is attractive as long as the existing steam plant is relatively new and has a lot of life left in it. It would be less attractive if the steam turbine is old, obsolete, and overdue for its trip the scrap yard anyway.

@Rod Adams

True in part, generators can be and have been readily replaced. When a company goes through the cost-benefit assessment as to whether to place an SMR as a replacement to a coal furnace, I’m sure that this factor along with the condition of the site would eliminate some coal power plant sites. I would also expect that having access to an existing water source, a working switchyard and existing transmission lines would also be a big benefit given the difficulties that obtaining new water rights and constructing new transmission corridors have had in getting their permits/licenses, land rights/right of ways, etc. So, it could go either way, you would just have to crunch the numbers and see where you land.

I also think that SMR companies like X-Energy see some PR advantages with showing people (and especially the politicians) concerned about climate change that they could readily replace “evil” coal with “clean” nuclear.

Just some thoughts…..

Enjoy!

@Andrew Benson

Thank you for the good question. It will be interesting to find out why X-Energy made the choice they did.

When I worked at FSV, several engineers told me that various water traps were proposed but discounted as there was an underestimation of the types of transients the plant could experience. Not sure what HTR-10, HTR-PM, or the Japanese HTTR use for helium sealing, but magnetic bearings with strong liquid traps should work.

As for timelines, my future grandchildren can get my FSV belt buckle out of mothballs when an HTGR is built in the US 😉 At least HTR-PM is under construction in China.

@Robert Margolis

How old are your children? Not prying, but want to understand the length of your timeline prediction.

I have no idea, myself. I would say that my grandchildren will be fascinated to see the simulated pebble I’ve been keeping for the past 20 years when there is a new high temperature pebble bed reactor in the US. Since I already have four grandchildren, three of whom will soon be old enough to understand the story, that time could happen any day.

My best guess is that there will be a demonstration plant operating before I’m eligible for full Social Security – that is 11-12 years from now.