Why did the Carbon Free Power Project get cancelled? What does that mean for NuScale?

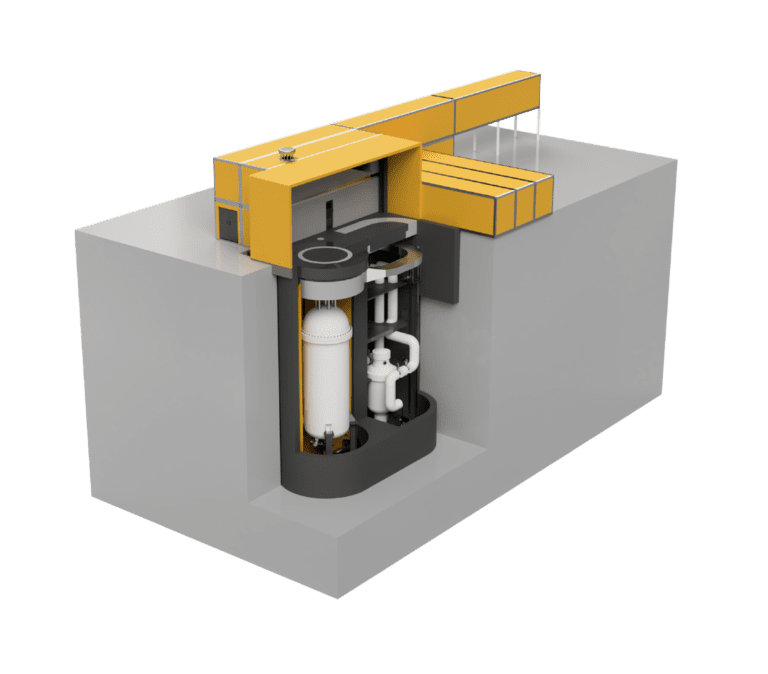

I’ll start with a disclosure. I’m still long on NuScale in my personal portfolio and have no intention of changing that position in the near future. I believe that the company has a good product and excellent potential for growth. The image above with Jose Reyes and me is from a visit I paid to…