Atomic Show #276 – HolosGen Claudio Filippone and Chip Martin

HolosGen has attacked the nuclear power plant cost and schedule challenge from the opposite direction chosen by many nuclear reactor developers. Claiming to be agnostic about the reactor specifics – as long as it produces reliable heat in a small-enough configuration – HolosGen founder Claudio Filippone decided to focus on radical improvements to the “balance of plant.”

Filippone worked for a decade as a consultant specializing in power production systems. He is both a nuclear engineer and an electrical engineer with the skills required to address a wide variety of systems and challenges. His advice was valued and sought after, allowing him to accumulate both ideas and resources.

He began the groundwork for HolosGen in 2008 and incorporated the company in 2017.

During his time as a consultant, he recognized that “the balance of plant” outside of the nuclear portions of a power plant represented 70-80% of the initial capital cost and a similar portion of the ongoing operations and maintenance costs. That was his inspiration for choosing to focus on radically improving that section of the system.

As the submarine sound silencing saying goes, “attack the big noise first.”

The fundamental choice enabling dramatic improvement was to abandon the Rankine (steam) cycle and switch to the Brayton (gas turbine) cycle.

He worked with visionaries inside the US Army’s technical branches to gather requirements for mobile generators that could safely and reliably operate under extreme conditions. The challenging requirements included resistance to focused kinetic attacks.

By choosing to meet performance requirements provided by one of the toughest customers available, Filippone and his HolosGen team have produced a design concept that can be manufactured and delivered to almost any customer in any location.

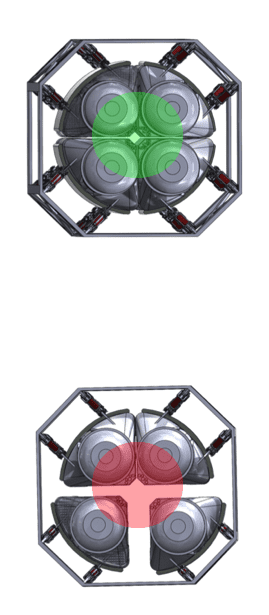

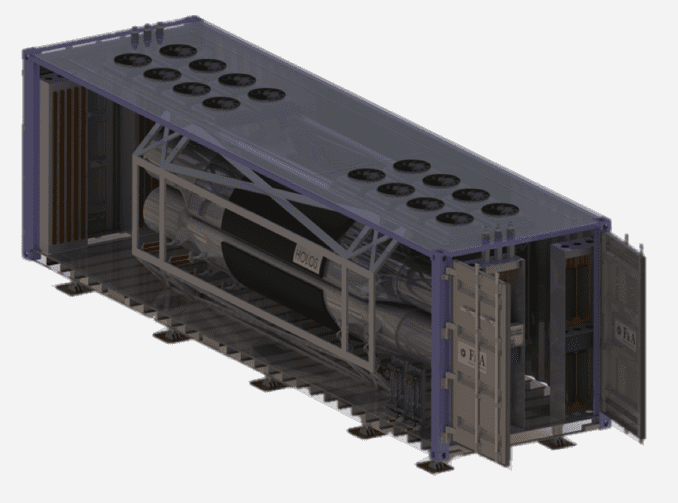

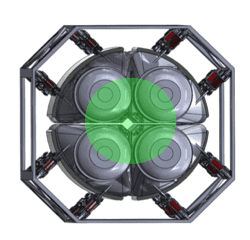

Copyright HolosGen. Used with permission

The integrated power production system can fit inside of an ISO standard 40 foot long container. It will come in a number of different sizes depending on customer needs. One version will have a designed power capacity of 10 MWe.

Filippone credits the ARPA-E Meinter program for helping HoloGen to achieve rapid progress in a radically new direction.

He has hired a team of creative, aggressive, dedicated engineers, machinists and technicians – mostly fresh out of school or the military – and carefully trained them with a program that includes a healthy dose of hands-on work with functional components.

He has inspired them with a vision and a mission to fundamentally change the way that nuclear energy can be put to useful work for society.

The machines that he and his team have produced – and they have produced several functional prototypes – are modern, closed Brayton Cycle heat engines that use high-speed compressors and expanders that are coupled electrically, not mechanically.

That configuration enables modern control systems to finely balance the compressor output with the turbine input, maximizing thermal efficiency over a wide range of power outputs.

They will work with a variety of gases, including helium, nitrogen and supercritical CO2.

Filippone has engaged the advisory services of Charles (Chip) Martin, a deeply experienced and well-connected nuclear professional. Immediately prior to joining HoloGen, Chip was the Glenn T. Seaborg Science and Engineering Policy Fellow for the American Nuclear Society.

Dr. Filippone and Chip Martin joined me for a fascinating and detailed conversation about their integrated nuclear power system in a box.

The show is a bit longer than normal, but I think you will find listening to it will be a valuable investment of your time.

As always, comments are welcome.

Podcast: Play in new window | Download (Duration: 1:27:39 — 100.4MB)

Subscribe: RSS

Please comment on the issues raised in the following Twitter thread, including the illustrations therein. Thnx.

https://twitter.com/FrantaJaro/status/1262749988787896322

The Holos concept looks to be based on an old submarine propulsion scheme, using Brayton cycle — itself derived from GE’s work on nuclear jet engines at INL in the 1950s.

That used ocean water for shielding.

Holos has almost nothing, like the jet engines.

An important feature of Brayton engines is that the intake and exhaust ducts represent radiation shine pathways [plus the reactor is full of holes too].

GE put much effort into mitigating that issue with their jet engine design, but it was still nowhere near complying with existing dose standards.

I’m glad Holos claims to be ‘agnostic’ about the reactor specifics, because the hydraulically-actuated quadrant 4-pack has always bothered me for being gimmicky and not solving one problem in any other nuclear system. Achieving shut-down and trimming temperature (or power) isn’t particularly challenging in any proven reactor system – they all have their knobs – so why trim with geometric buckling [read leakage]? Shippingport Core 3 operated in sort-of the same vein with movable ‘seed’, which had terrific peaking (bad) of like 8 peak-to-average. The Holos actuator appears to be a novice idea where the lead designer was intrigued when he figured-out that geometric buckling was a thing. Looks good in a shipping container and the DOE/DOD wants reactors in shipping containers… Varying gap in a LWR assembly spacing wildly increases edge rod peaking – a certain amount is accounted for in analysis. Corner pins in BWR fuel assembly might be 1.5% enriched in a zone of 4.5% average enrichment for this reason. I’m not saying that variable geometry doesn’t have a place in the future of nuclear reactors – it is actually one of the more elegant solutions to managing the necessary evil of excess reactivity in solid-fueled reactors, but in this case, I’m not seeing a benefit because the diameter is so small and the spectrum so hard (no water) that it’s going to need HALEU to get hot. Just stick with rods or reflector or poison.

Aren’t inlet temperatures of combustion power turbines on the order of 1600-2000C? You might get temperature like that out of a hot spot in a solid fueled reactor, for a few moments, before the core slumps. NERVA cores didn’t last long – erosion was measured in % mass loss per hour. Space geeks always say they were ‘such a success’.

Basically, the only reason to have variable core geometry is to conserve neutrons to reduce/eliminate poison – that would be useful for a breeder reactor like shippingport core3 with conversion ratio barely above unity. In the case of an SMR that is a burner like Holos, it only adds unnecessary complexity.

@Michael

Did you listen to the show? Dr. Filippone explained another reason for segmented cores in generators that have a requirement to be transported even after they have been operated.

@Michael

I’d also like you to challenge your personal assumptions. Even though control rods are well proven technology, do you honestly believe that their complexity is less than a control system that can be actuated from completely outside of the reactor and its neutron flux?

RE: “Aren’t inlet temperatures of combustion power turbines on the order of 1600-2000C?”

Yes.

But this is a closed cycle machine, operating at high pressure, with a better gas than air.

So that’s not the issue.

I’m guessing they could get fairly decent performance with He/Ar/Kr or SCCO2.

But their shielding looks like a bikini from Ipanema beach.

Similar issue to Oklo’s Aurora heatpipe reactor — although at least theirs is supposedly buried in the ground.

@Jaro

Dr. Filippone has indicated to me that he will be visiting and responding to some comments here. He should be able to address your questions about shielding.

For both scaryjello and Jaro – have you ever done any calculations on the effect of reactor gamma radiation levels from eliminating O2 from exposure to neutron flux?

I’m not capable of performing the calculations and have no access to suitable models, but I have a seared memory of training that emphasized the fact that oxygen gets activated by neutrons. The process creates an intensely radioactive isotope of Nitrogen – N-16. It has an 8 sec half life and produces a 6 MeV gamma.

Navy training gives some thumb rules for the impact of N-16 in water coolant. But standard LWR fuel is an oxide, so N-16 must be formed within fuel rods and must also be a contributor to the gamma doses produced by the reactor.

If fuel contains no O2, would gamma doses fall? Would this effect be significant? I’m honestly asking for some help in quantifying an intuitive thought.

@Rod

Cross-section of an (n,p) reaction on O-16 is 0.1 barn in the thermal spectrum, so effect must be miniscule.

@MikeE

Thank you for the information, but I think it would be more important to look at the cross-section for the reaction in a fast spectrum. My question was about the O2 component in the fuel matrix itself. Seems to me that a substantial fraction of the neutrons that hit O2 atoms that are part of UO2 are not yet thermalized.

But other people’s answers have convinced me that O2 activation is not a major source of reactor boundary radiation.

The fuel oxygen is obviously not an issue, given the overwhelming gamma and neutron source of the prompt fission and buildup of fission products.

It is an issue in the coolant, especially well away from the core. That’s why BWRs have a lot more concrete in the turbine building – mainly for N-16 shielding. It’s not a major engineering challenge or anything, just some more concrete and steel. In PWRs it affects the shielding needed for the steam generators, though as they are in containment this is a reduced issue in exposure terms.

After a few minutes of shutdown the activity is gone so there is no offline maintenance issue from the N-16.

RE: “oxygen gets activated by neutrons. The process creates an intensely radioactive isotope of Nitrogen – N-16. It has an 8 sec half life and produces a 6 MeV gamma.”

This reaction has a threshold of over 10MeV – extremely rare in fission (less than 1pct).

And the reaction x-section is only a few tens of millibarns.

C13 production is much more likely.

Also, U235 fission prompt gammas can also have 6 MeV energy, with similarly low probability.

Finally, shielding gammas is less problematic than shielding neutrons. That’s what it’s about, with reactors.

Figures:

https://pbs.twimg.com/media/EYeArjWXsAEXExg?format=png&name=medium

https://pbs.twimg.com/media/EYeAuYkXYAALpsV?format=jpg&name=medium

Rod, I am deeply impressed that Claudio Filippone has been willing to become a knowledge worker that uses all his senses and all his experience and knowledge. We have reduced the concept of development to the point that only a person behind a keyboard is a “developer.” Those who develop with their hands have nearly become a lost breed of individual. My respect and admiration go out to Mr Filippone and his team! Yes! Comfort itself is a block to development. Passion is key. It is no wonder that the Absent-Minded Professor was filmed in 1961 when many companies still had that kind of passion and sacrifice.

I am also impressed that his technique to control the reaction was submerged beneath the “we never did it that way before” crowd. I hope he implements it!

Finally, being willing to allow things to fail is a key part of development. Stressing parts until they fail gives real feedback on their actual capacity.

What a great interview!

Good One! I presume that was Eisenhower at the beginning and end of the show. Time tells us who the good leaders and poor leaders were. I think he was one of the good ones.

Very impressed by Claudio Filippone. Using variable speed drives to control the gas turbine compressor seems like a good idea since the shaft to the combustion baskets will no longer be there.

I liked his little speech at the end where he discussed the reasons why men of the last generation could achieve so much whereas less appears to be happening today. It reminded me of the picture of Thomas Edison sleeping at his work bench due to the long hours he put in.

What a fresh and interesting new approach! It’s nuclear, sure, but it’s a lot more than just that, and the different nuances touched by Rod, Claudio and Chip, including that of human flourishing and dedication to one’s life passion, made it all the more interesting.

I will definitely keep my eyes peeled on any developments from HolosGen in the future.

Thanks Rod, you have taught me so much in nuclear, I will always be extremely grateful for your willingness to share information with anyone who is keen to listen.

Ciao, Luca

Dr. Filippone read through the comments as of Sunday, May 24. As you heard during the interview, he is a busy man who fills his days with hard work trying to get his company’s product ready for the market.

He sent this information to me after 8:00 pm on a Sunday evening and indicated that he prefers to avoid getting into back and forth discussions on the Internet. Knowing what I know about the industry he’s in and the regulators who oversee it, I’m sure he already spends a lot of time answering questions.

With that preamble, here is his response to the issues raised in this thread.

Cut and pasted from Dr. Claudio Filippone to Rod Adams Sunday, May 24, 2020 at 8:15 PM.

_____________________________________

I wanted to first thank Rod for organizing the show. His truly good questions during the show greatly helped focusing answers on critical aspects. Again, thank you. Rod as promised I am addressing some of the comments, and I apologize for addressing them with a few days of delay.

Starting from the initial comments, some comments assume the Holos concept is based on an old submarine….derived from GE’s work……almost nothing, like jet engines…

– To my knowledge there are no old or new submarine systems that use the Holos concept.

– It is not derived from GE’s work. The designs in the 1950s used a mechanical shaft on ball bearings (requiring lubrication). The shaft was relatively long and had to go through the center of the nuclear core. This generates a series of problems with the shaft materials (irradiation issues), rotor dynamic, vibration and reliability issues. The GE design adopted control rods to control reactivity and an open-air Brayton as thermodynamic cycle. The Brayton was a conventional open-loop air standard thermodynamic cycle with turbo-machinery of compressor and expander mechanically coupled. Holos does not have mechanical couplings between compressor and expander (no shaft in the middle of a nuclear core), no ball bearings, lubrication systems and lubricant exposed to radiation (Holos rotary components are magnetically levitated through Active Magnetic Bearings), and no control rods through the core. Control rods are by no means simple, for each rod, there must be a control-rod drive sleeve, a control-rod drive mechanism with brakes, an actuator generally positioned outside the core pressure boundary, sensors and redundant control logic systems. There can be hundreds of control rods even in a small core. Generally, each control-rod is as long as the active core length. This forces a “jungle” of control-rod sleeves outside of the core occupying almost the same volume of the core. In most design the control rod sleeves pose pressure boundary challenges. For these reasons control-rods are not simpler. They are just well-known and generally accepted. Achieving reactivity by displacing subcritical power modules with respect to one another requires substantially less actuators. Enables elimination of control-rod drive mechanisms and sleeves, and offers additional methods of achieving safe shutdown (cold shutdown and hot) by using gravity to displace selected subcritical power modules. This design approach optimizes the volume available for systems, structures and components within the constraints of a shipping ISO container. This approach is not more complex it is simply not well known, even though various configurations of these systems have been successfully tested since the 1950s. The “flyable reactors” programs of 70 years ago had to factor systems volume and mass with more stringent engineering requirements than those applied to terrestrial and marine applications. As these systems were not further pursued, the knowledge-base acquired at that time has been for the great part lost. As a result, methodologies to simplify reactivity control mechanisms to achieve reductions in their dimensional footprint are easily perceived as more complex than more conventional methodologies (e.g., control rods).

Regarding jet engine aspects: Consider a turbo-jet engine to which the combustors are replaced with nuclear fuel cartridges. Except, instead of using combustion of air and fuel mixtures Holos uses the heat generated by a controlled neutron-coupled nuclear core. Holos conserves the compressor-expander configuration of jet engines with elimination of balance of plant, and positions the heat source between the compressor and expander (e.g., replacing the combustors with a nuclear heat source). This is as close as you can get to key features characterizing open- and closed-loop turbo-jet engines. The cycle is a closed-loop Brayton with intercooler and recuperator heat exchangers to further boost efficiency. And these heat exchangers are embedded with the compressor components (no conventional balance of plant).

Radiation aspects: Holos closes the loop by intubating the resulting engine so that the working fluid keeps recirculating and rejecting thermal energy with the environment via heat exchangers thermally coupled on one side to the working fluid and to environmental air to the other side without physically mixing the working fluid with environmental air. In the 1950s the GE nuclear jet engine had the core directly exposed to air with minimum infrastructure acting as radiation shield. “Direct shine” was unavoidable as these engines had to intake air with as little obstruction as possible. Holos is intubated with turbomachinery on the compressor and expander side protected by radiation shields. No direct shine. In the 1950s there were also nuclear airplane designs that used a closed-loop turbojet engine system. In these closed-loop configurations, the reactor core was positioned in the fuselage and thermal energy was transported via liquid metal from the core to heat exchangers positioned between the compressor and expander or power turbine, thus replacing the combustors with heat exchangers hydraulically coupled to the core. This design configuration provided better shielding compared to the direct shine radiation reflected by the runway back to the airplane crew. However, it was also adding so much weight that the resulting airplane would perform poorly.

Temperature and efficiency aspects: Holos Brayton cycle results in a power plant efficiency of approximately 44% with the core outlet temperature at 850C. The efficiency factors working fluid friction, heat exchangers actual effectiveness and losses in the electromagnetic machines. The max design temperature is lower than combustion temperatures. As a result, expander turbomachinery components are less challenged by temperature in the Holos design.

Radiation aspects: The coupled core is shielded axially and radially and there is no direct contact of environmental cooling air with core internals. However, as air surrounds the system, Argon gas contained in the air becomes activated for a few hours. All other isotopes in the air have very short-half lives. When operational, and if operated above ground, the design is surrounded by a non-invasive (non-permanent) prefabricated “shield building” ( with walls formed by concrete, rebars and boron). The shield building is equipped with a relatively small stack to dilute the activated Argon in the air. A perimeter fence surrounding the shield building at 50 meters from its walls reduces dose rate substantially below NRC safety margins for the general public – you could stay at the fence for the whole year and not exceed the annual safety dose rate.

Hope my comments are helpful.

Claudio

I am currently studying the HolosGen reactor concept. It is a revolutionary design that has many applications (power gen, process heat, hydrogen production, etc.). I am wondering if the bearings for motor/compresser and expander/generator modules could be further simplified and made more reliable with porous media type air bearings? See NewWay Air Bearings (www.newwayairbearings.com) for further information on this type of bearings. The circulating working fluid could be used as the bearing with lifting force provided by the differential pressure between the compressor discharge/suction. The porous media bearing can act as both a conduit to distribute the gas fluid across the bearing face and also as a secondary landing bearing. This may reduce the energy input required for the magnetic bearings and remove some modes of failure.

the only problemo is that nobody seems to want a SMR and certainly not a portable one even in Russia people weren’t happy with a floating one

What makes you say that “nobody” seems to want an SMR?

There are several customers who are spending substantial sums of money to help develop SMRs into a complete product. There are others who have expressed real interest in buying once there are complete products (licensed, with proven detailed designs, training, maintenance procedures, spare parts, etc.) available.

It takes time, especially under the conditions that have been established by decades worth of efforts (often by competitors) to discourage development.