Atomic Show #313 – Stefano Buono, Founder and CEO of Newcleo

Stefano Buono is a physicist and the successful founder of Advanced Accelerator Applications, a multibillion dollar company that pioneered the use of several therapeutic medical isotopes. After making several people very rich, including himself, he sold the medical isotope business and returned to his early 1990s field of study – nuclear fission reactors using molten lead as a coolant.

About two years ago, Stefano Buono and some of his colleagues and associates founded newcleo, a company with Italian roots based in the UK. Last year, newcleo ran two successful rounds of start-up funding that netted the company a total of €400 M. After passing through several important milestones, it is raising a subsequent round with a target of €1 B for continued development and for a state-of-the-art fuel manufacturing plant.

Dr. Buono visited the Atomic Show to share his insights on the paths to success as an entrepreneur in a deeply technical and undervalued field and on the role that timing – both planned and fortunate – plays in business success. He is convinced that it is a good time to be building a nuclear fission energy company.

Lead cooling for reactors has a long history with some demonstrated success. In the 1970s and 1980s, the Soviet Union operated a class of submarines called the Alfa class, which were famously the fastest and deepest diving submarines in the world at the time. Seven subs were completed and operated with both impressive performance and technical issues that limited their reliability and service life.

The reactors in those submarines were metal cooled thermal reactors using lead-bismuth eutectic for cooling and beryllium for moderation.

The collapse of the Soviet Union and subsequent economic conditions halted most lead cooled reactor development in Russia, but it resulted in a diaspora of Soviet scientists and engineers that stimulated research and development of the technology in Europe, especially in Italy and Sweden.

For several reasons, the lead cooled reactor community moved from lead-bismuth towards pure lead and away from beryllium moderation.

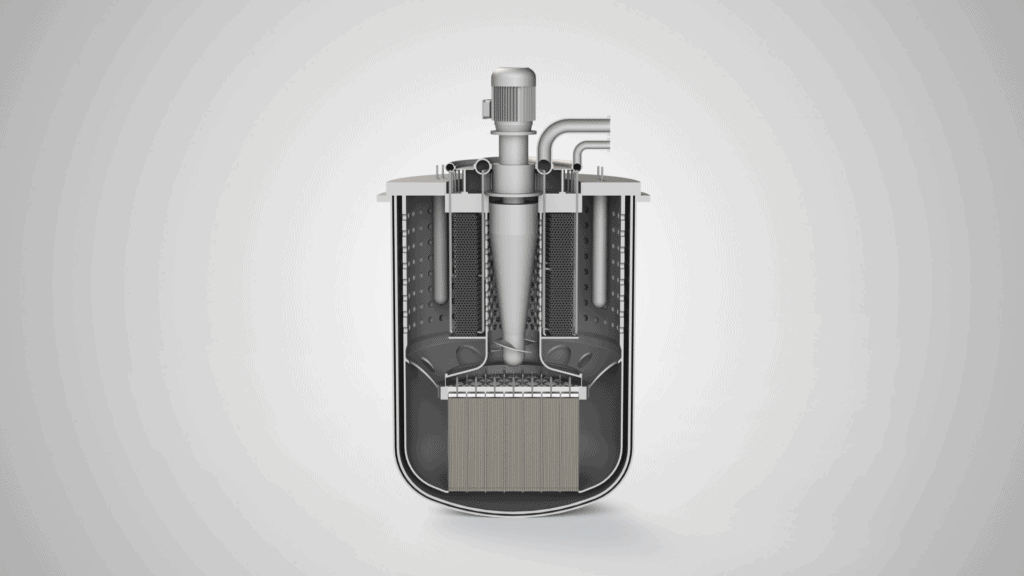

Compared to water, lead is virtually invisible to neutrons, letting fission neutrons remain in the fast spectrum. Fast neutrons will fission all actinide materials, allowing reactors to advantageously consume the long-lived components of used nuclear fuel and to breed new fuel from fertile materials like Uranium 238.

Lead remains in liquid form at temperatures far above reactor operating temperatures, eliminating the need to pressurize the coolant system. Compared to sodium, the molten metal that has been used more frequently by reactor designers, lead is not subject to explosive or flammable reactions if it comes in contact with water or air. Though sodium-cooled reactor designers have devised ways to ensure safe use of their chosen fuel, the techniques require additional systems and components that add cost.

One disadvantage of lead has limited its attractiveness as a coolant. At the temperatures of interest for a reactor, corrosion rates in contact with stainless steel can cause operational problems. For the Alfa class submarines, corrosion products created some clogging issues – mainly in small diameter piping like that found in steam generators.

newcleo, Stefano’s company, is taking advantage of research and development conducted during the 40+ years since the Alfa’s were designed and operated. That research and testing has proven several different techniques that can be used to limit the effects of corrosion and that also offer the opportunity for future improvements that will enable even higher operating temperatures in subsequent reactor models.

During Atomic Show #313, we talked about advantages and challenges of lead cooling, the use of mixed oxide (MOX) fuel, the company’s phased technology development program, its licensing strategy, its options for initial deployment and the reasons that now is a great time to be developing nuclear fission power systems in Europe.

This show should provide plenty of food for thought. Please participate in the discussion using the comment features here.

Podcast: Play in new window | Download (Duration: 1:02:15 — 73.4MB)

Subscribe: RSS

Fascinating episode, thanks

Lead coolant is not free from challenges; obviously the Russians found adequate or reasonable solutions to the flow accelerated corrosion in ferrous piping (alumina forming alloys). I seem to remember managing slag was also challenging and complex, and that a lot of that oxide came from the pipe walls. A young Westinghouse engineer was exuberantly describing their lead-cooled concept, which emerged from in-house phenomenological identification and ranking efforts, at a dog and pony show last year. He claimed it was the most economical solution – lowest cost of operations. While figuring out the details of how to manage the fuel cycle in such a system would be a fun 25-year ride to the end of my career, I just don’t see where the savings would manifest. It sounds like typical academic reactor thinking. Fast reactors like BN600, BN800 and these lead-cooled types need regular (annual, semi-annual for BN600) outages to DE-FUEL when they operate with breeding ratio > unity. I’m 100% certain these spatially well-coupled cores aren’t suited to refueling while underway, based my own experience attempting to manage single assembly asymmetries in cores with a lot more feedback (PWRs). I give all the gen4 reactors a grade of “meh”. They’re certainly going to cost a lot, at least initially. They’re certainly going to have radiation protection challenges. They’re certainly going to have teething problems, and they don’t really improve any parameter my company would be interested in as an operator. They’re just different. The fuel isn’t scarce; we don’t need breeders.

In my opinion, LWR’s are the problem, not the solution. They have by far the lowest thermal efficiency of any power generation system on the planet and are obscenely wasteful of nuclear fuel. Gen4 designs address all of these issues. The breed and burn/travelling wave core setup enabled by fast reactors is a no-brainer for game-changing reductions in refueling outages, to say nothing of the fuel utilization and waste management benefits. The VHTR and GCFR have the potential for net efficiencies far in excess of 50% along with massive reductions in balance of plant. Of course there are material challenges but there are no technological show-stoppers, only a lack of will. As far as high FOAK costs go, LWR’s had to deal with those as well. LWR’s have served us well during the long periods of innovation stagnation and anti-nuclear sentiment, and sustaining the current fleet makes sense, but when it comes to new builds, their fundamental shortcomings are no longer justifiable.

Thank you for beginning the response with “in my opinion.” Did you know that piston internal combustion engines have significantly less than the 30% efficiency of LWRs, and that they are also used for power generation, thus your statement is false. The “obscenely wasteful” nature of the LWR fuel cycle is a relative and subjective measure, considering there aren’t other types of reactors online for comparison, save a pair of SFRs and a pair of PBMRs. LWRs are often benchmarked against the CANDU; the former uses about 10% more feed uranium as a trade-off for online refueling. Coincidentally, the waste volume/mass from the LWR is 90% less than the CANDU. The CANDU will discharge 9 tons at 6 GWD/TU for 1 ton of LWR waste at 50 GWD/TU. The PBMR fuel is mostly graphite and is very bulky – my estimates are PBMR will discharge 25X the waste volume of high level waste (spent fuel). That is quite a trade-off for an extra 10% efficiency in the steam cycle – not to mention the PBMR cores are designed tall and narrow to allow radial conduction of decay heat in accident scenarios. This poor aspect ratio leaks a lot of neutrons and requires 10% enrichment (more than double the LWR). The SFR, and breeders in general, would only make sense if reprocessing fuel was cheap and clean; it is neither. Equipment used to separate spent fuel into waste streams becomes extraordinarily contaminated and unserviceable upon use, not to mention all the other very public, sometimes non-technical concerns (proliferation). So, what we have here is your opinion, likely based on what you’ve read on blogs, print or watched on youtube. I sympathize with pronuclear folks like you. Still, I’ve spent a lot of time in plant design as well as plant operations and I can tell you that your opinions are not particularly enlightened or different than most consumers of pop science.

@Atomstroyexpert

As a nuclear reactor engineer, you may have some valid points. But as a nuclear power plant engineer, you might be missing a few important facts.

1. Most piston internal combustion engines used to generate power are large compression ignition (diesel) machines that can achieve thermal efficiency of 40%. That is not 10% higher than LWRs; it is a 33% improvement. ((40-30)/30)

2. Current design choices for PBMR are not necessarily representative of the ultimate design choices that might be made after refinement. There is no truth to the assumption that waste mass cannot be reduced if necessary after use. It’s not that difficult to conceive of processes that remove the graphite if that is an exercise worth doing.

3. The tall core that enables passive heat rejection in the case of an accident might be wasteful of neutrons, but it eliminates a lot of external, safety grade systems. Those with detailed knowledge and understanding of complete HTGR system economics have apparently come to a different conclusion. Experts can differ, especially when their expertise is limited to their areas of specialization.

I’m not an engineer, but I think that lead cooling combined with Moltex’s molten salt fuel in fuel pins might just be the ultimate approach to making a small reactor that produces lots of cheap electricity/heat.

I understand why they are using MOX, you can actually buy and use it today. Using it rather than molten salt fuel is one less risk on the path to getting to a viable first reactor in operation.

One question I have is – would lead cooling be better than molten salt cooling for getting higher output temperatures for hydrogen/chemical fuel production?

One advantage of MOX fuel is that bad agents cannot use it to breed pure Pu239. Fresh MOX fuel already has a high content of denaturing Pu240, its ratio only increasing with burn up.

I enjoyed listening to Rod’s interview with Dr. Buono, and I found it to be quite informative on many subjects.

I’d like some clarification about MOX as the standard process for fuel recycling, in countries that manufacture and use it.

My understanding is that MOX is dependent on PUREX as a method for producing chemically purified plutonium oxide, which is then mixed with uranium oxide to form MOX recycled fuel. Is that correct?

My understanding is that PUREX was developed at the beginning of the Cold War when nuclear weapons production was top priority. It seems perplexing to me that PUREX is still the most common basis for fuel reprocessing nearly 80 years later, when public opposition to nuclear energy is its chief obstacle and nuclear waste is its most frequently cited public concern, with weapons proliferation often cited as an argument against fuel recycling. However, there is no US federal law that actually prohibits nuclear reprocessing, nor any actual connection between civilian nuclear power reactors and military nuclear weapons production. (See “FAQ: Recycling Nuclear Waste”; URL: https://www.goodenergycollective.org/policy/faq-recycling-nuclear-waste)

Maybe what we need is a business model for nuclear waste disposal as a distributed service, using small fast reactors as its power-producing and waste-reducing implementation, and using deep boreholes on the fast reactor site as geologic repositories for the reduced waste, which should consist entirely of fission products once all the useful actinides in the input waste have been converted to 100% carbon-free electricity.

If someone comes up with a way using IFR-style electro-metallurgical reprocessing to produce recycled fuel compatible with today’s slow-neutron power reactors, then perhaps we will have broken out of the PUREX rut that seems to have constrained fuel recycling since the Cold War years. (See “Pyroprocessing Technologies” from Argonne Labs; URL:https://www.anl.gov/sites/www/files/2023-09/Recycling%20Used%20Nuclear%20Fuel%20Brochure.pdf ).

In any case, the output of the IFR-style reprocessing can be used as IFR did, as input for fast reactors.

What do you think?

Since posting my previous comment on this thread, I’ve learned about another property of MOX fuel that poses a problem in its use to improve the sustainability of thermal reactors. Use of MOX in fast reactors is fine; it’s thermal reactors that have a problem. Here’s an article in Wikipedia that explains the problem (“MOX fuel”; URL: https://en.wikipedia.org/wiki/MOX_fuel).

Under the subheading “Spent MOX fuel”, the article says:

“The content of un-burnt plutonium in spent MOX fuel from thermal reactors is significant – greater than 50% of the initial plutonium loading. However, during the burning of MOX the ratio of fissile (odd numbered) isotopes to non-fissile (even) drops from around 65% to 20%, depending on burn up.”

My understanding is that this behavior is due to continued neutron absorption causing fissile Pu239 to evolve through even & odd numbered Pu isotopes, then into minor actinides. Again, while this is OK in fast reactors, in thermal reactors it makes the usability of the Pu isotopes unstable. Thus, the use of MOX in thermal reactors is limited in countries that use it to a special “twice through” fuel cycle.

IMO, a better model for fuel reprocessing would be to separate mostly fertile Uranium from fission products, which should be disposed in deep boreholes, and from mixed actinides, which should be recycled as fuel for fast reactors. This is summarized in a flow diagram in the PDF cited previously from Argonne Laboratories (“Pyroprocessing Technologies”; URL: https://www.anl.gov/sites/www/files/2023-09/Recycling%20Used%20Nuclear%20Fuel%20Brochure.pdf). In the flow diagram, look for an arc from a “separations” unit to an “enrichment” unit, the latter presumably designed for enrichment of mined uranium.

Using this model, the outputs of “enrichment” units would be either HALEU for Gen4 advanced Uranium-fueled reactors, or LEU for remaining conventional power reactors. Isotopes of Plutonium and other transuranic (TRU) elements would be reserved for Gen4 fast reactors. This model would retain the considerable advantage of keeping Uranium resources in circulation until their fissile content decreases below the threshold of usability in power reactors. At this point, IMO the nuclear industry would have successfully put the other 99% of Uranium resources to good use.

Here’s a comment on a business case for HALEU.

This is from a reading assignment from Raluca Scarlat, Assistant Professor of Nuclear Engineering, UC Berkeley (“Characterizing an Emerging Market for High-Assay, Low-Enriched Uranium Production: HALEU Production Cost Analysis and Market Program Evaluation”; URL: https://nuclearinnovationalliance.org/resources):

“Recent projections from Idaho National Lab (INL) suggest a cumulative production of 5,350 MTU of HALEU will be needed by 2050 to support deep decarbonization goals, with a production rate of approximately 520 MTU/year required by 2050. To meet this substantial demand, the United States must swiftly ramp up its HALEU production capacity (with corresponding increases in uranium production) to ensure that future reactors have an ample supply of fuel to generate clean energy.“

IMO, one of the best ways for the US DOE to help achieve the necessary ramp up of HALEU production would be to implement a robust conversion program to extract unused uranium from used reactor fuel and use it as enrichment feedstock, independent of expanded uranium mining. Using a domestic, standalone electrometallurgical reprocessing method could greatly reduce environmental and economic costs associated with uranium mining and PUREX based legacy reprocessing technology.

Indeed, the idea of recycling reprocessed uranium (“RepU”) from used nuclear fuel is corroborated in this week’s World Nuclear News (“French reactor using full core of recycled uranium fuel (01 Mar 2024)”; URL: https://www.world-nuclear-news.org/Articles/French-reactor-using-full-core-of-recycled-uranium). This is major good news for improving sustainability of nuclear energy without dependence on new mining or importing mined uranium from foreign sources.

Note that when Gen4 fast reactors come online (e.g., Newcleo’s lead-cooled fast reactor), a real solution to nuclear waste disposal will be available in the form of additional closed fuel cycles. Until then, mixed actinides from spent fuel can be collected and accumulated in temporary storage, and fission products from thermal reactors can be stored long-term (300-500 years) in deep boreholes.