History and promise of high temperature gas cooled reactors

By: Diarmuid Foley

A small modular nuclear reactor to replace coal plants could be on the market within 5 years.

In 2014, the Generation IV international forum[1] confirmed the Very High Temperature Reactor (VHTR) as one of 6 promising reactor technologies that should be pursued in order to develop advanced reactors suitable for deployment in the 2030’s.

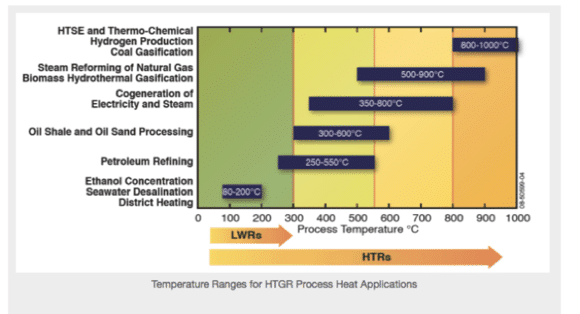

The VHTR design was initially targeted at reactor outlet temperatures of up to 950 -1000 °C for process heat applications. Such temperatures would enable the thermo-chemical production of hydrogen and other products without producing carbon emissions. Electricity generation would use a direct-cycle helium gas turbine.

In recent years, commercial development has focussed around reactors with output temperatures in the range 700-850 °C using a steam cycle, as this range is seen as having the greatest near-term potential. These designs are now referred to as High Temperature (Gas) Reactors – HTR or HTGR.

Figure 1 : Key industrial process heat applications and operational temperature range for light water reactors ( LWR ) & high temperature reactors ( HTR )

History

The HTR has more than 50 years of somewhat chequered history behind it. The first plants were small experimental ones – a 20 MWe unit in the UK & a 15 MWe unit in Germany that came online in 1966. This latter was followed by a commercial unit that was designed to burn thorium. However, the German project ran into political and technical headwinds and was abandoned in 1989.

In the U.S. 2 commercial (i.e. power producing) plants were built – a 40 MWe experimental unit at Peach Bottom which ran from 1966-1975 and provided the learning foundation for the much larger 330 MWe plant at Fort St Vrain, which ran from 1976 to 1988. This latter reactor established the technical feasibility of HTR’s although further development was required to justify the economic case.

Design & technical details

Most HTR’s use helium as coolant, but super-critical CO2 and nitrogen can also be employed.

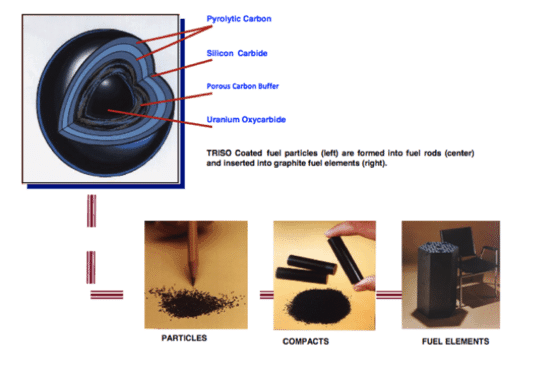

Figure 2 The HTR uses many billions of individual fuel elements

The distinguishing feature of all high temperature reactors is the use of TRISO (Tri-Structural Isotropic) fuel, placed either in a pebble-bed or a prismatic block type configuration.

The solid fuel is encapsulated inside extremely small silicon carbide/carbon casings of less than 1mm diameter. This provides for a highly secure containment of the fuel and fission products during operation and indeed for spent fuel as no water or active cooling system is required for spent fuel storage.

TRISO fuel particles are designed not to crack due to the stresses from processes (such as differential thermal expansion or fission gas pressure) at temperatures up to and beyond 1600 °C, and therefore can contain the fuel in the worst of accident scenarios in a properly designed reactor.

This fuel from is currently being used in two experimental reactors; the HTR-10 in China, and the HTTR in Japan.

High efficiency

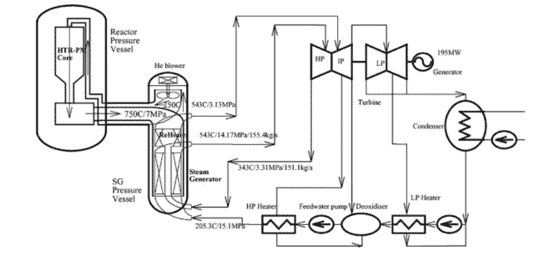

HTR reactors have thermal efficiencies of ~42% on steam cycle and potentially 50% or greater on a gas turbine cycle. Demonstration and proving of a coupled gas turbine remains a high development priority.

Safety case

An important safety feature of the pebble-bed reactor is that it will not crack, melt, explode or spew hazardous waste, even if all of the supporting machinery fails. It simply goes up to a designed “idle” temperature, and stays there. While it radiates a manageable amount of heat, the vessel and fuel spheres remain intact. Accordingly the HTR design is recognized by the IAEA as “inherently safe” as it cannot melt down.

The design also benefits from a very strong negative coefficient of reactivity. Furthermore as helium has a very low neutron cross-section, it is not easily activated and presents no risk of radionuclide release in the event of a coolant escape.

Plant siting

One of main attractions of the HTR design is that there is no requirement for large volumes of cooling water, which in conjunction with the greatly enhanced safety case, means plants can potentially be sited much closer to centers of use.

Spent fuel & waste

Spent fuel can be stored without an active cooling system – air circulation is sufficient. Furthermore, the fuel form is ideal for long term storage.

Chinese program

There are government sponsored HTR programs in China, Japan and South Korea but it is the Chinese program that is the most interesting.

In the 1990’s, the Chinese licensed the considerable work that had been undertaken in Germany in earlier years and set about resolving the technical issues that had beset the program there. It began construction of its first experimental reactor of 10 MWe in 1995 at Tsinghua’s university energy centre – the Institute of Nuclear and Energy Technology or INET – and this unit went critical in 2000, subsequently supplying power to the campus.

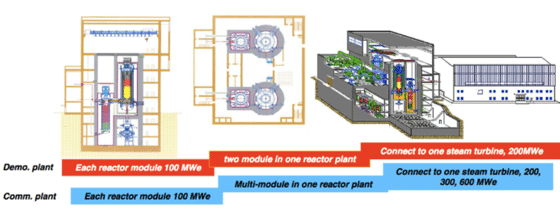

Figure 3 China’s HTR program is built around standard 100 MWe modules which can be coupled to a single steam turbine.

This proved an operational success and as a result a decision was taken to build a full-scale demonstration unit[2] [3].

Construction of this unit began in 2012 at Shidao Bay, some 900 km south east of Beijing. This will consist of two modules of 100 MWe coupled to a steam turbine. They are designated HTR-PM which stands for High Temperature Reactor, Pebble-bed Modularized. Construction is at an advanced stage and the units are expected online in 2018.

Potential substitute for coal plants

One of China’s stated goals for developing the HTR is that they have the potential to substitute for the combustion unit in its fleet of modern supercritical coal plants, as they produce similar steam turbine inlet conditions. As many of China’s coal plants are located close to cities, this is seen as a potential route for quickly improving air quality.

Economics & mass deployment

The concept is firmly based around volume production of standardized modules. The target capital price for serial production is $2 – $2,500/kW of capacity and the Chinese are very clear on costs – they want utilities to choose these units over coal technology.

Figure 4 Schematic of China’s HTR-PM. Steam turbine inlet conditions are similar to modern coal plants, circa 550C

The HTR-PM modules can withstand complete loss of pressurization and helium flow without a forced shutdown and still not release enough radioactive materials to exceed the very conservative dose limits in place today.

According to Professor Zuoyi Zhang of INET, the design is such that up to 6 modules can be combined to give some 600 MWe of power, which is similar to the size of more modern supercritical coal units.

“This technology is going to be on the world market within the next five years,” Zhang predicted in 2016. “We are developing these reactors to belong to the world.”

North America

The U.S. adopted its own advanced reactor initiative in 2005 (termed the Next Generation Nuclear Plant or NGNP [4]). The program is presently focussed on qualifying the TRISO fuel to the satisfaction of the regulator, along with other supporting tests at national laboratories.

Current commercial design and engineering developments in North America are being led by X-Energy & General Atomics in the U.S. and Starcore Nuclear in Canada.

Maryland based X-Energy is developing a 50 MWe module which can be arranged to form a plant up to 200 MWe. In 2016 it was awarded a 5 year $40Million grant by the Department of Energy to further develop its technology in conjunction with leading national nuclear laboratories & private companies.

Meanwhile, General Atomics has developed the conceptual design for a 265 MWe fast spectrum HTR. It is unclear how advanced this program is.

But licensing reform in the U.S. remains the key issue.

Although the U.S. regulator – the NRC – has recently issued its vision statement for the licensing of non-light water reactors[5], the timeframe – with full implementation not until 2025 – remains a major impediment and frustration for U.S. developers, who have indicated that more fundamental reform needs to happen, much sooner.

Canada

Canada successfully developed it’s own water-cooled reactor, the heavy water based CANDU design. It is seen by many reactor developers as one of the more attractive Western markets in which to seek to first license an advanced design.

StarCore began the pre-licensing engagement process (known as the Vendor Design Review) with the Canadian regulator, CNSC, in November 2015. This is expected to take up to 18 months after which the company will be in a position to decide whether to proceed with a full license application.

Starcore’s technology is also based on using TRISO encapsulated fuel in a pebble bed prismatic configuration. They have designed a unit size of 20 MWe expandable to 100 MWe.

The company’s business plan is to sell electricity rather than sell reactors. Their target price at up to $140/MWh is high for large grids but their market is remote communities which would typically be paying considerably more than this for diesel-generated electricity and heat.

Industrial process heat (IPH)

A strong logic underpinning HTR development is its potential use for generating industrial process heat. A recent EU-funded research program[6] put the global market for industrial heat at 946 – 1,376 Mtoe, although the immediately accessible market for nuclear heat is estimated to be smaller at 260 – 430 Mtoe, equivalent to

3 – 5,000 TWh/year. Such a market would require at least a doubling of current reactor capacity.

Furthermore, this report estimated that 2/3rd of IPH is required at temperatures below 700°C which fits with the HTR’s operating range.

This is a substantial market considering that global energy use – from all sources – was 13,684 Mtoe in 2014[7].

Economics

A key reason for developing the HTR is its inherently safe design. The majority of the equipment in current large water-cooled reactors is redundant safety systems which adds enormously to cost as well as regulatory complexity. With a simplified safety case and volume production, costs are projected to halve, making this design competitive with modern coal-fired plants. Levelized costs of electricity of less than 6.5¢/kWh are projected.

Future developments are expected to take advantage of the much higher efficiencies that a direct cycle, based on a gas turbine, can offer. Research on this technology is on-going at many of the locations mentioned.

The next couple of years promise to be interesting for advanced nuclear. All eyes will be on China’s demonstration unit and whether it can prove that this design is ready to enter commercial operation in the next decade.

About the author. Diarmuid Foley is an engineer and advocate for nuclear energy. He holds a masters in nuclear engineering from Imperial College London and is currently researching advanced nuclear for electricity and industrial heat applications at University College Cork. Twitter : @DiarmuidFoley1

[2] https://www.iaea.org/NuclearPower/Downloadable/Meetings/2014/2014-04-08-04-11-TM-NPTDS/2_Li01.pdf

[3] https://www.iaea.org/NuclearPower/Downloadable/Meetings/2015/2015-08-25-08-28-NPTDS/DAY1/5._DONG_Y-201508V2.pdf

[5] https://www.regulations.gov/document?D=NRC-2016-0146-0002

[6] http://cordis.europa.eu/result/rcn/56098_en.html

[7] IEA – World Energy Outlook 2016

UC Berkley and ORNL believes that the cost of these reactors can be lowered substantially by Cooling them with Molten Salts, rather than gas. Because Nolten Salts are far more effective at heat transfer, the size of reactor cores can be shrunk in a very impressive way. As a result the cost of solid fuel reactors using the same Graphite encased nuclear fuel can be dramatically lowered. This technology will take about ten years to develop, and China needs a Coal replacement nuclear technology now. Clearly a bird in the hand is worth two in the bush.

@Charles Barton

Per Peterson (UC Berkeley lead on the molten salt cooled pebble bed reactors) and I have had numerous conversations on this topic. He is correct about the impact of using molten salts on the size and power density of the reactor heat source.

My emphasis, however, is and always has been on the total cost, size and weight of the complete nuclear power system, including what most nuclear engineers dismissively call ‘BOP’ (Balance of Plant).

Molten salt cooling of a pebble bed reactor locks in a requirement for a large, technically challenging and expensive heat exchanger to transfer the heat in the molten salt into either boiling water to produce steam or to heat some kind of gas.

Per’s favorite choice currently (along with Charles Forsberg of MIT) seems to be heating atmospheric air to run through a conventional gas turbine and to have the additional capability of adding even more heat to that air by burning natural gas when power demand is sufficient to cover the additional fuel costs.

I wish them good luck in their development efforts.

More effective approach is to directly drive the gas (combustion) turbine’s air compressor using a helium turbine- compressor. Roughly doubles the electrical output of the gas turbine’s generator. Using today’s very large gas turbines, can generate over 950 MW electric (combined-cycle) while using over 80% of the energy in the fuel gas (~630 MW thermal gas reactor) This is the essence of the patented hybrid-nuclear technology.

The advantage of heating the gas turbine’s air with a reactor is not that great.

Would be great to get an update on the progress of this project.

Let me check with Rob and see if we could add something to his website.

In a very brief summary, we have completed the concept design and are getting ready to submit an information summary to the NRC.

Plant produces ~950 MW, with a more classical approach to economics; make it bigger, better & more efficient than the competition. Quite different than tha SMR approach.

You’re talking about greatly increasing the core’s power density by relying on a liquid coolant, correct? Would that mean that if the coolant were (somehow) drained out of the reactor, the fuel pebbles temperature limits would be exceeded? Assuming the answer is yes, are you (at least) saying that no active (forced) cooling is required?

You state that these technical changes will dramatically reduce the cost of the reactor. Rod points out that reducing the size of the reactor (which is only a small part of the overall power plant ) may not reduce costs as much as you think.

I have different ideas about what actually drives the cost of nuclear power (to an even greater degree). My view is that technology has relatively little impact on overall cost. Instead, it is excessive regulations and QA that drives costs. That is, it’s the cost of the “paper”.

As I expressed in my other post, my hope is that if we have a reactor design where it is sufficiently obvious that it is inherently safe, we can make the case for greatly reducing those requirements. The changes you’re talking about make inherent safety significantly less obvious. Unrealistic as it may be, the fact is that you would have a problem if there was a loss of coolant (unless I’m missing something). It is more plausible that various changes in configuration (and failure of function) could cause a significant release, which will in turn lead to everything having to be “full-Q”.

Therefore, my opinion remains that it would be better to go with the larger reactor core volume but argue for reduced requirements (e.g., everything but the fuel kernels is NITS). The overall cost would end up being lower.

I agree with the “larger reactor core volume but argue for reduced requirements” idea. In fact, there are concepts that do that (http://hybridpowertechnologies.com/index.html). Also, one must consider the extra costs that the “full-Q” requirements add to the engineering (additional detailed reviews, reports, and approvals) and construction labor (additional expensive specialized inspections, ultra-detailed work packages, excessive hold points, ultra intensive receipt inspections, rigorous care and maintenance requirements, etc.) costs that arise in nuclear facility construction.

Has anyone ever compared the quality requirements for hazardous chemical production / utilization facilities (where a release would severely harm / kill everyone down wind) to those of a nuclear power plant?

IIUC, the use of an atmospheric-pressure coolant allows the use of a pool-type primary coolant loop which makes LOCAs close to impossible. You can have a small, cheap, power-dense reactor core in a big, relatively cheap tank.

The Chinese are right about one thing, the price target does indeed need to be 2.0-2.5 dollars/watt. Not just in China but in the US as well. We need to find a way to reduce nuclear plant costs by at least a factor of 2, if nuclear is to have any future.

One more point, related to the one above. As far as I’m concerned, given the inherently safe nature of this reactor, the fuel pebbles should be the only Important-to-Safety components of this reactor. If I understand the description (given by the author) correctly, if the fuel pebbles perform as designed, no other components of the reactor system (or the failure thereof) have any potential to cause a significant release. No change in the reactor configuration could cause their temperature limit to be exceeded. Am I missing something?

@Jim Hopf “…Am I missing something?”

Maybe. Defense in Depth. As a philosophy, in which unforeseen failure modes affecting one barrier are “caught” by a redundant barrier.

I do realize that the true defense in depth was diluted considerably when the AEC allowed active safety features to protect the containment integrity; and that was a long time ago (1960s).

But still, one barrier? What about “unknown unknowns” and can we expect the regulators to buy into it? I have my doubts. I think they will still insist on some kind of containment/confinement in addition to the pebble integrity.

gmax137

I agree.

Strikes us that the “functional containment” being pushed by some gas reactor developers is unwise for the reasons you noted. That is why our hybrid-nuclear approach employs a passively-cooled full containment. Impact on cost is not that great considering the hybrid produces about 950 MWe.

As far as Jim’s “What am I missing?” Number of potential problems could lead to massive radiation releases. For instance: (1) multiple steam generator tube failures flooding the reactor with water resulting in hydrogen generation and explosions, (2) large hole in the system leading to continuous oxygen infiltration and burning of fuel (graphite does burn if it gets hot enough). While these are admittedly very unlikely events, a containment would make the consequences as more or less no big deal.

PS the Hybrid does not employ a steam generator.

SG failure could not flood the reactor if the reactor coolant was at a higher pressure than the boiler feedwater.

Helium is troublesome because of its minuscule MW. I’m surprised that nobody is using neon instead. It’s not close enough to air to use the same machinery, but it’s much closer than helium and it isn’t reactive with graphite at high temps like CO2.

It’s not. To get high efficiency from the steam cycle, steam pressure is very high. The gas pressure on the reactor side is much lower so currently approved steels can be used for the reactor vessel without excessively thick walls – gas reactor cores are physically very large because the fuel density is really low (fuel is not anywhere as near as dense as that used with water reactors)

Neon might work, however cost seems to have been a major factor in not pursuing it in the past.

Wrong. First of all, the graphite is not the “fuel”; it’s the moderator. The main factor that determines when graphite “burns” is the amount of impurities in the graphite. Nuclear-grade graphite is very pure. Therefore, while technically it will “burn” (i.e., ignite), it does so only in an oxygen-rich environment, which is not going to happen in an air-ingress event.

The worst case is that the surfaces of the graphite blocks or pebbles oxidize, which while not desirable, is not the same thing as “burning” and doesn’t lead to “massive radiation releases.”

No. Gas reactor cores are physically large because carbon (i.e., graphite) is a less efficient moderator than hydrogen (i.e., water). Therefore, an epithermal, gas-cooled reactor looks “small” to neutrons compared to a thermal, water-moderated reactor, even though the physical size is much larger.

The fuel density — that is, the power density — is a parameter that can be selected by the reactor designer, subject to the restraints imposed by achieving sufficient moderation for the core.

The power density of gas reactors is significantly less than water reactors. That is why water reactors are relatively compact (great for submarines) and gas reactors are not (too big for submarines).

The ability of reactor designers to modify power density is limited by the basic physics of the type of reactor. Gas reactors are fundamentally different than water reactors because the neutron moderating capabilities of water and carbon are quite different.

Re: core burning – large hole in system

The fuel is surrounded by carbon, both the moderator and material coating the fuel particles. If carbon gets hot enough, it will begin to oxidize (burn) releasing energy. If the heat is not removed fast enough and oxygen keeps showing up, temperatures rise and the coatings surrounding the fuel particles fail, releasing highly radioactive fission products.

Much easier to simply use a containment which prevents oxygen fron continuously showing up and radiation released. Saves time & money by avoiding never ending efforts to convince skeptical regulators that everything is fine without a containment.

@Mile Keller

While graphite dust may be flammable, solid or bulk forms of pure graphite are not.

https://cameochemicals.noaa.gov/chemical/25027

f. Although most reports on the Chernobyl accident refer to a number of graphite fires, it is highly unlikely that the graphite itself burned. According to the General Atomics website (http://gt-mhr.ga.com/safety.php): “It is often incorrectly assumed that the combustion behavior of graphite is similar to that of charcoal and coal. Numerous tests and calculations have shown that it is virtually impossible to burn high-purity, nuclear-grade graphites.” On Chernobyl, the same source states: “Graphite played little or no role in the progression or consequences of the accident. The red glow observed during the Chernobyl accident was the expected color of luminescence for graphite at 700°C and not a large-scale graphite fire, as some have incorrectly assumed.”

WNA: Chernobyl Accident, Further Information.

Doesn’t mean hot graphite didn’t ignite asphalt roofing material.

Has everyone forgotten Windscale, the fire in its graphite moderator… and also Fort St. Vrain, whose graphite moderator being corroded by reaction with water leakage from the circulator fan bearings was one of the major reasons for closing it?

Maybe pyrolytic graphite won’t burn by itself, but in a reactor core heated by FP decay it’s not by itself.

Keeping oxygen out appears to be a sine qua non. It may also be sufficient.

Can anyone explain why the outermost layer must be carbon, and not SiC? That also might be sufficient.

RE: Meanwhile, General Atomics has developed the conceptual design for a 265 MWe fast spectrum HTR.

Question: If a gas cooled reactor operates in the fast spectrum, can an Adams Engine become more feasible? Specifically, if N2 coolant is exposed to a fast spectrum, is the formation of Carbon 14 substantially mitigated?

@Rick Armknecht

Good question. I’ll check with my neutronics experts.

May I answer this one?

Under a fast neutron spectrum, say MeV region, the neutron capture N-14(n,p)C-14 is about 2 orders of magnitude lower than for thermal neutrons.

I have uploaded the cross section here: https://postimg.org/image/enz3an9dv/

Taking into account the low number density of a gas with respect to a liquid or of course a solid, the macroscopic cross section will be even lower and the production of C-14 should be rather “low”. I am not a safety expert, but this production may still pose concerns from a safety point of view, as all this C-14 will be in a form of mobilizable inventory, that in case of a reactor depressurization would have to be expanded and contained.

Thanks. Limiting C-14 production in N2 coolant seems to be the “bottleneck” technology for an Adams Engine. Glad that there is a possible approach with fast reactors (sure seems easier than establishing an N-15 separation industry).

Maybe a slightly modified regulatory environment will make the difference, too.

@Rick Armknecht

It’s easier to change minds from falsehoods to truth than to change physical facts. (Of course, that is a minority opinion.)

C14 I can’t see as much of an issue an activated carbon filtration system would remove a large % of the C14 produced. C14 isca minimal radiological hazard currently encountered in fuel reprocessing reactor operation of LWR and decommissioning of magnox reactors.

Biggest issue with fast spectrum gas reactors is the loss of thermal mass in the reactor core. The thermal mass plays a huge part in preventing temperature excursions in the fuel for the first hour after shut down. After that decay heat power levels have dropped to roughly 1% of reactor power which can be managed via radiation and conduction.

Also the loss of a conductive material to draw heat away from the fuel is also hard to overcome in the fault scenario.

I’m involved with development of a molten salt reactor with the objective of generating electricity cheaper than coal (and maybe natural gas). Cost is critical to create the economic incentive to stop burning coal for electricity.

There’s also a good argument to develop TRISO-fueled, gas-cooled reactors because they can approach 1000°C temperature, which can potentially enable high-temperature water-cracking to make cheap hydrogen. Cheap hydrogen is the essential ingredient for any synfuel that hopes to be able to competitively replace gasoline and diesel petroleum-sourced fuels.

In solving the climate/emissions/energy crisis, replacing coal is going to be easy compared to replacing oil.

Just want to mention Los Alamos’s UHTREX (Ultra High Temperature Reactor Experiment), which ran from 1959 to 1971.

Just want to add a clarification that StarCore changed their design from pebble bed to prismatic about two years ago (not that you could tell from their terrible website). They presented something very similar to the Japanese HTTR at the 2015 Canadian Nuclear Society meeting and again at the 2016 ITMSR conference.

Has anyone ever tried to reprocess TRISO fuel?

@Syndroma

Yes. It’s done routinely with fuel that has not be irradiated yet; a significant portion of the fuel particles do not pass quality assurance tests. The coatings are stripped and the fuel kernels are recycled into the incoming stream of fuel material.

There is no pressing need to recycle used fuel yet, but the fuel that gets discharged from an operating reactor is in a stable form for storing without any cooling system required.

I not so sure it is that routine. The Silicon-Carbon coatings are tough to dissolve with acids if trying to get at the Uranium/ Plutonium. Trying to crush the particles to get rid of the coatings does not work very well either.

Might have a chance of recycling material if you are only trying to get at the SI-C coated particles before the fuel is actually used in a reactor. Even then, would be challenging as the fuel pellets are fired at pretty high temperatures to turn the pellets into the final product. Would need to recycle before firing.

@Mike Keller

I’ve seen the process working. Coatings need to be completely removed to allow the fuel material to be properly coated so particles pass QA inspection (automated because the particles are so tiny and numerous) process.

What is the source of your information?

Acids can be used to chemically remove Plutonium from conventional nuclear fuel. That is a pretty routine process.

However, TRISO fuel is quite different due to the Si-C coatings surrounding the fuel particles. Numerous articles on recycling TRISO fuel for reprocessing Plutonium. It is just plain very difficult because the coating resist acid attack.

Please identify your sources; what process is being used?

@Mike Keller

I saw the processes working in the place where the particles are manufactured. I cannot point to published sources; a good bit of useful material isn’t published by those who own the IP.

You sure they were not dealing with fuel particles that had not been fully fired? Once the stuff is turned into a fully processed TRISO particle, it’s damm difficult to undo.

Meanwhile, Rick Armknecht says “General Atomics has developed the conceptual design for a 265 MWe fast spectrum HTR”

INL did a conceptual study of a Deep-Burn HTR yielding 50% – 80% burn up of Pu containing TRSIO: US VHTR Deep Burn Activities (pdf), a slide presentation whose page 16 mentions “Centrifugal jet milling to separate coatings from kernels” as an early step in TRISO reprocessing.

They concluded that their DB-HTR was quite feasible, but would still send significant minor actinides to the repository if the original fuel was recycled from LWRs: that job really calls for fast-spectrum reactors.

Another reprocessing-related question is how much C14 spent TRISO fuel contains.

Apparently enough to separate during graphite recycling. See above INL reference.