Can prototype nuclear reactors be licensed in the US under current rules?

Designers and developers of nuclear power systems that are substantially different from conventional light water reactors face a conundrum. They are required to provide sufficient information to regulators to allow them to confidently predict how the designs will behave under a comprehensive set of postulated operational and accident conditions. Proving their design is safe is a time-consuming, question-filled challenge that is even more difficult without an operating system on which to verify analysis assumptions.

Modeling can only go so far without real data. Creating partial test loops or integrated system testing installations consumes substantial resources without exercising a supply chain useful for a full scale system. NuScale and former mPower employees can testify to the challenges.

In 10 CFR 50.2 Definitions: prototype reactor “means a nuclear reactor that is used to test design features, such as the testing required under § 50.43(e). The prototype plant is similar to a first-of-a-kind or standard plant design in all features and size, but may include additional safety features to protect the public and the plant staff from the possible consequences of accidents during the testing period.”

Aside: We’ll come back to paragraph 50.43(e) later. End Aside.

Using prototypes can be a way to accelerate development. They are common in a variety of industries that need approval from public safety regulators, most notably in the automotive and aviation industries. One might ask why it has been more than five decades since they were last used in atomic energy development in the United States.

Types of Atomic Energy Licenses

Chapter 10 of the Atomic Energy Act of 1954 (AEA) is titled Atomic Energy Licenses. Chap 10 Section 101 states that production or utilization facilities using special nuclear material need to have licenses issued under section 103 or 104. Section 103 is titled “Commercial Licenses” and its first sentence refers to a finding under section 102.

Section 102 imposes a practical value test which says that a facility that is sufficiently developed for industrial or commercial use should obtain a section 103 license.

Section 104 is titled Medical Therapy and Research and Development. Its initial three paragraphs describe different types of licenses, (a) medical therapy, (b) facilities that can provide the information required to support a finding of practical value required in Section 102, and (c) facilities that are useful for research and development but not expected to be useful in industrial or commercial purposes. University research reactors are examples of the types of facilities that obviously qualify under paragraph c.

But a prototype facility that is designed to be used to test reactor plant designs that are not familiar to either customers or the NRC is arguably not a facility that has proven that it has a practical value. Logically, it should not be required to be licensed as a commercial facility under Section 103.

Looking at just the Atomic Energy Act, it would seem that prototypes as defined in 10 CFR 50.2 should be licensed under Section 104(b) .

It’s not that simple.

10 CFR Part 50, which is the regulatory code enact the licensing provisions of the AEA, includes statements under “Classification and Description of Licenses” that indicate that a major change was put into effect on December 17, 1970. That change removed Section 104(b) as a licensing option. There are grandfather clauses and a clause that allows section 104(b) to be used if directed by a specific law.

The change also modified Section 104(c) in a way that allows prototype reactors. It says “(c) A production or utilization facility, which is useful in the conduct of research and development activities of the types specified in section 31 of the Act, and which is not a facility of the type specified in paragraph (b) of this section or in § 50.22.”

Paragraph 50.22 contains a definition of a commercial reactor that allows a full scale prototype to use Section 104(c) as long as it operates within given limitations. A production or utilization facility “is deemed to be for industrial or commercial purposes if the facility is to be used so that more than 50 percent of the annual cost of owning and operating the facility is devoted to the production of materials, products, or energy for sale or commercial distribution, or to the sale of services, other than research and development or education or training.”

If the sale of materials, products, energy or services does not produce more than 50% of the annual cost of the facility, it is not automatically considered to be an industrial or commercial facility.

The testing schedules of prototype reactors would almost certainly preclude those devices from being able to cover 50% of their annual costs – including amortization, interest and depreciation – by selling materials, products, services or energy. That is a common feature of prototypes: no airplane developer or automobile manufacturer expects their flight test and certification planes or concept cars to be commercially viable. They consider them to be part of the development expense enabling them to sell a series of products.

I’ve been discussing this potential path for licensing non-light water reactors for at least a decade with people inside the industry, starting with a paper I wrote for my former employer at B&W mPower. Those discussions revealed either skepticism that the effort would be accepted by the NRC, a concern that it would not be a valuable way to speed the licensing process, or a desire to follow through with the mandated development of Part 53 as a new licensing path for non light water reactors.

After the NRC staff released its proposed draft of Part 53, The Breakthrough Institute issued an analysis explaining why implementing a rule based on that draft without major changes will impede progress. BTI’s Ted Nordhaus and Adam Stein also published a blog post titled NRC Staff Whiffs On Nuclear Licensing Modernization that ends with a scary conclusion:

…there is little reason to expect that the first advanced reactors will be licensed and demonstrated by the end of this decade, nor that the US will have the nuclear technologies available at scale in the coming decades that the world will need to deeply decarbonize the US and global economies.

NRC Staff Whiffs On Nuclear Licensing Modernization

Since developing a new process seems to be too hard to do correctly, it’s time to invigorate older processes that already exist.

It might be useful to take a brief detour to explore the reasons why no one is pursuing this prototype path – yet.

History of nuclear power prototypes

The US Naval Nuclear Propulsion Program has long recognized the training, testing, supply chain and experience value of full scale prototype nuclear reactors, especially for system designs that are either completely new or a significant change from previously used designs.

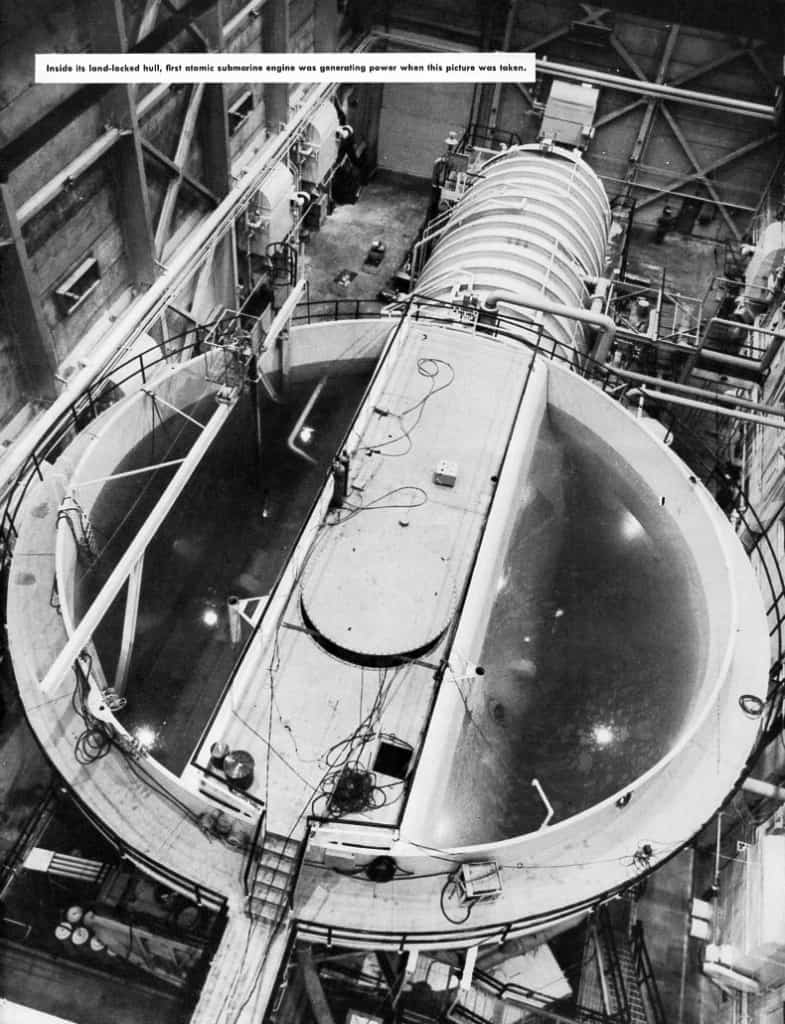

Navy nuclear prototypes have been as much like the power plants installed in ships as possible. STR-1, the prototype for the USS Nautilus reactor, was so realistic that it was installed in a simulated submarine hull with a large tank full of water around the portion of the hull containing the reactor plant.

For about two decades after STR-1, the Navy continued building land-based prototypes for nuclear propulsion plants that were significant departures from proven designs.

Full scale prototypes can be just as useful for commercial nuclear plant vendors. The people who drafted and enacted the Atomic Energy Act of 1954 recognized the value of prototype reactors that were as close as possible to commercial designs. The Navy’s STR-1 had been operating for about a year by the time AEA 1954 was passed into law.

Until 1970, nearly all US nuclear power plants were licensed under Section 104(b) as “facilities involved in the conduct of research and development activities leading to the demonstration of practical value of such facilities for industrial or commercial purposes.”

The facilities were being purchased by utilities to produce industrially useful power stations without going through the antitrust provisions of Chapter 16 of the Atomic Energy Act. They were also qualified to receive substantial subsidies from the AEC under the theory that the new facilities would “lead to major advances in the application of atomic energy for industrial or commercial purposes.”

Part 104(b) also directed the Atomic Energy Commission, whose licensing responsibilities were transferred to the Nuclear Regulatory Commission in 1974, to “impose the minimum amount of such regulations and terms of license as will permit the Commission to fulfill its obligations under the Act to promote the common defense and security and to protect the health and safety of the public and will be compatible with the regulations and terms of license which would apply in the event that a commercial license were later to be issued pursuant to section 103 for that facility.”

Part 104(b) licenses were useful and helped jump start the American nuclear energy industry. One might legitimately wonder what happened to force a regulatory change to remove this type of license.

Soon after the Oyster Creek nuclear power station won a commercial bid without overt subsidies, atomic energy competitors, led by the National Coal Policy Conference (NCPC), claimed that the concentrated nuclear power industry was taking unfair advantage of Part 104(b) provisions. These atomic energy competitors engaged in strong, sustained political actions designed to push the AEC to make a “finding of practical value” for light water reactors that had been sufficiently well-developed to attract utility customers.

Their argument was simple and logical – if pressurized water and boiling water reactors were winning customers and were being built as facilities that would be operating for decades as baseload power plants, then any reasonable person would consider them to be of “practical value.”

In early 1964, Joseph Moody, President of the NCPC, stated his group’s position succinctly.

There can be no question that they are of “practical value” – or else they would not be used to supply commercial power.”

Balough. Brian “Chain Reaction” Cambridge University Press 1991. p. 208

The controversy over the AEC’s practical value determination lasted 6 years and involved a number of congressional hearings and court cases. The saga fills 13 pages in Brian Balough’s exceptionally well-researched book titled Chain Reaction: Expert debate and public participation in American commercial nuclear power. 1945-1975.

One reason that the “coal boys” (Balough’s term) ultimately won the war after losing several battles was that nuclear power plants had been scaled to such a large size that the Congressional overseers of the AEC (the Joint Committee on Atomic Energy) and responsible courts agreed there was a need to perform the Justice Department’s antitrust review required by Chapter 16 of the AEA for Part 103 commercial licenses and avoided under Part 104(b).

Even the most stubborn defenders of the AEC’s policy to avoid making a finding of practical value realized that their position was difficult to justify for large, light water reactors similar to those that were being ordered at a rate of dozens per year with a peak of 7 reactors in a single month (Feb 1967) .

Prototypes can be important for non-light water reactors and advanced reactors with uniquely new design features

Unlike the large light water reactors that were being constructed on a large scale by mid 1970, when the AEC made its practical value determination for pressurized and boiling water reactors, today’s advanced reactors are several steps away from a reasonable person’s definition of “practical value.” They still qualify as prototypes.

A prototype licensing process would follow the two-step (construction permit followed by an operating license) process defined in Part 50. It is more suited for projects with expected changes in detailed design during construction and which are are unlikely to be built in a repeatable series. It’s also the licensing process that recognizes the substantial value provided by prototype reactors in § 50.43(e).

(e) Applications for a design certification, combined license, manufacturing license, operating license or standard design approval that propose nuclear reactor designs which differ significantly from light-water reactor designs that were licensed before 1997. Or use simplified, inherent, passive, or other innovative means to accomplish their safety functions will be approved only if:

(1)(i) The performance of each safety feature of the design has been demonstrated through either analysis, appropriate test programs, experience, or a combination thereof;

(ii) Interdependent effects among the safety features of the design are acceptable, as demonstrated by analysis, appropriate test programs, experience, or a combination thereof; and

(iii) Sufficient data exist on the safety features of the design to assess the analytical tools used for safety analyses over a sufficient range of normal operating conditions, transient conditions, and specified accident sequences, including equilibrium core conditions; or

(2) There has been acceptable testing of a prototype plant over a sufficient range of normal operating conditions, transient conditions, and specified accident sequences, including equilibrium core conditions. If a prototype plant is used to comply with the testing requirements, then the NRC may impose additional requirements on siting, safety features, or operational conditions for the prototype plant to protect the public and the plant staff from the possible consequences of accidents during the testing period.

(Emphasis added)

10 CFR 50

Notice that there are two alternative paths for supporting the approval of the safety functions of reactors that are not light water reactors licensed before 1997. (There is a reason for using bold print to emphasize the OR between paragraphs (1) and (2). Developers need to firmly and effectively establish their chosen path and not allow anyone to attempt to impose additional elements from the alternative path.)

The second path involves a sufficiently designed test program of a prototype plant that has extra public protection features that might include using a remote site, adding special safety features (like an over-designed containment structure) or enhancing staffing requirements.

It is nice to know that the regulations for obtaining approval for a commercial license offer the opportunity to prove reactor safety using a prototype. Unfortunately licensing experts and regulators appear to be convinced that precedence demands that full scale prototypes need commercial reactor licenses.

Why haven’t reactor designers chosen the prototype path described here?

Decisions to avoid prototypes using Section 104(c) are reasonable in a paradigm applicable to extra large nuclear plants. Owners of projects that cost $5 to $10 billion or more would suffer unacceptable losses if they had a licensing provision that prohibited them earning more than 50% of their annual costs from selling materials, products, services or energy.

That provision isn’t an unaffordable barrier for small and very small reactors, especially if the cost accounting for the prototype is fully burdened with design and development costs plus a depreciation schedule that recognizes the abbreviated lifetime of prototypes.

The revenue limitations might be a significant barrier for some SMR designers if they overlook the fact that their prototypes would be allowed to produce unrestricted income from R&D and training. Prototype owners also have the option of applying for a commercial license after their plant proves itself to be of practical value during a testing, training and verification phase as a prototype.

Note: Vendors don’t have to use prototypes. They can choose to follow paragraph 50.43(e)(1) and find customers based on obtaining license approvals from component and system testing with detailed analysis. The prototype path is an alternative route that might avoid a significant portion of the overhead of proving that the analysis was sufficiently comprehensive. End Note.

Prototypes will be one of a kind, though some might be successful enough on the first try to eventually become FOAK commercial units holding Part 103 licenses. Limitations on earning income from sales of materials, products, energy or services contained in Section 104(c) are sufficient barriers to prevent applicants from repeating the mistake in the 1960s of creating justifiable animosity by overusing the special encouragements available for non-commercial plant licensees.

Even the US Navy eventually determined that it was no longer cost-effective to build complete prototypes for new reactors that were moderate extrapolations of existing reactors.

Note: When the Navy stopped building prototypes, their training and testing functions were deemed important enough to repurpose reactors that had served their time as ship propulsion plants but still had remaining useful life. Many of today’s nuclear sailors are trained on moored training ships (MTS) that were once active submarines. End Note.

In a period with multiple advanced reactors under development, none of which have proven that they are of practical value, a smoothed path towards full-scale prototypes could be immensely useful.

To achieve this desirable result, NRC regulators must fully accept their responsibility under Section 104(c) to “impose only such minimal amount of regulation of the licensee as the Commission finds will permit the Commission to fulfill its obligations under this Act to promote the common defense and security and to protect the health and safety of the public and will permit the conduct of widespread and diverse research and development.”

Congressional direction doesn’t necessarily need new legislation. It can come in the form of hearings and required testimony along with letters that direct the NRC to follow existing laws.

It’s not too late for today’s reactor designers to make a switch to Part 104(c) license applications if they determine it is advantageous and if the NRC regulators express their support for a path that would lead to more reliable safety determinations in a shorter period of time.

This seems like a very promising path for microreactors especially! I wonder if USNC is considering this path for their university reactor? I have also long wondered if we could “cheat” some licensing by making a subcritical test facility. This would be especially helpful for designs that are going after less mature fuel and coolant types and need data about thermo-radio-chemical issues in their designs. The new SHINE Mo-99 facility is effectively an accelerator-driven subcritical aqueous homogenous reactor and their NRC licensing didn’t seem to arduous. 10’s of kW class beams to drive sub-critical prototypes would add ~$1M to the cost, which may be acceptable IF the licensing is easier. Of course such a machine wouldn’t be useful for power production, but it could be used for training, radiation testing and even isotope production!

@Gerrit Bruhaug

While your ideas have merit, this post is specifically aimed at blazing a path for a full scale prototype that is as close to a production machine as possible. It would use the same pumps, valves, piping, control systems, sensors, etc. Of course some features of the design might prove inadequate during testing, but that it one of the reasons for testing full scale machines approved through a less arduous process with public safety being assured with external precautions that would not be required for commercial machines.

Ron – Your article is outstanding. It needs to be published in ANS Nuclear News & posted in ANS Nuclear SmartBrief.

Thank you, Paul. I hope that others find it valuable and take the time to provide useful feedback, including pointing out logical or procedural errors. Public peer review is welcome.

Rod, an excellent piece of research and writing! It probably should be pointed out that Kairos Power is using a variant of this approach as we speak. Their proposed Hermes test reactor, while not a full size version of their KP-FHR molten salt reactor (about 10% of the planned full size design), is currently under review for a construction permit with staff work expected to be complete in 2023.

Gene – thank you for the kind words. Coming from a man with your experience, it’s high praise indeed.

I’m glad you appreciated the work.

I have a great deal of admiration and respect for Kairos’s well planned effort to move towards fully commercial power plants. Their scaled down Hermes will provide valuable data on both reactor performance and behavior of key materials under radiation.

But it won’t be able to provide all of the functions enabled by a full scale prototype. I’m especially interested in the way prototypes have potential to shorten the total path to full commercial production. They also can serve as a great marketing tool for customers that act like they are from Missouri and demand that vendors “show them” that the system they will be purchasing performs as promised.

Historical Fact:

Many years ago, I worked in the Licensing department at a Comnercial Nuclear power plant. Reading your article reminded me of a paragraph that was not in Title 10 CFR but in the Title 1 CFR [The Code of Federal Regulations (CFR) is the official legal print publication containing the codification of the general and permanent rules published in the Federal Register by the departments and agencies of the Federal Government.] At that time Title 1 CFR stated that the book had to be printed to be legal, technically. I found what I believe was that statement or a statement of verification by searching the internet. ” The Office of the Federal Register (OFR) began publishing yearly revisions for some titles in 1963 with legal effective dates of January 1 each year. By 1967 all 50 titles were updated annually.” Strangely they seem to enforce the rules in the various CFR’s within 30 days of approval. Rod should be able to verify this, but as a Chief Petty Officer for the Reactor Control division on a Submarine the “Naval Reactor” was also subject to 10 CFR. I clearly remember the RC Division Officer requiring that florescent lamps that package of waste discarded be tested for radiation and that the discharge of the material met the requirements of 10 CFR- in 1970 or 71. A job that I was glad went to the Engineering Lab Technician (ELT.)

Speaking for myself.

While the prototype provisions can provide a pathway to resolve some technical risk, the open ended “additional requirements” scare me. If a design is hoping to reduce costs through the use of concepts such as functional containment or an on-site EPZ and the “additional requirements” force a structural containment or remote location with full 10 and 50 mile EPZ, a prototype may do more harm than good. Thus, many developers may decide that it is better to move those discussions earlier and reduce licensing risk rather than push that risk farther out in time. Additionally, once a developer accepts the additional requirements for the prototype reactor, it might be hard to claw back the requirements for the commerical design. Path dependency is real.

People are distracted by the amount of work/effort it takes to license and build something other than a LWR – as if “prove it” is an unreasonable request from the regulator. Yes there may be three or four different paths to success in the CFR…. but that is not a problem.

Problem: not one of these concepts the government is supposedly dragging its feet on significantly improves costs, reliability, maintenance, operations, dose, disposal. In fact, all the concepts make at least one of those concerns worse.

Congress funded the VTR for a few years and then killed it. That’s a judgment on a segment of the Gen 4 offerings – this is consistent policy since before cancelation of IFR. SFR are judged: NOT BETTER for utility scale power generation. We don’t have to build a bunch of them to convince ourselves of this – we can simply watch the sideshows in Russia and China. Nobody wants to pay for detailed evaluation of a SFR plant that does not generate electricity as cheaply as an LWR. The fuel utilization improvement from the SFR is irrelevant because uranium is not scarce; if it were, incremental improvements to current fuel cycle could stretch the supply. Nobody gets excited about chopping up spent fuel rods, making a bunch of effluents in the process, to scavange mixed actinides to LOSE MONEY. The benefit to a MOX program is some hedge against interruption of supply (e.g. embargo), which isn’t an issue for the nation with the most lethal Navy.

Without going through the details of why not a single Gen 4 offering is promising, I’ll simply state: if it were better, it would have been built already.

You might have an opinion that a particular design is better, especially those that don’t exist, but that is just that (opinion). The LWR alternatives that are operating today like HTRPM and the BN800 are not making power more cheaply than a PWR.

It is hard to license a reactor. It must obtain unanimous agreement among all parties involved that the design improves things. The process only seems to break down when presented with a design that is not an improvement. In that case the process breakdown is a FEATURE not a bug.

@michael

If LWRs are superior, why did we stop building them for 4 decades and why aren’t there any projects following up on the great successes in Georgia? After all, there are still for active COLs for more AP1000s still active.

There are apparently thousands of people who don’t agree with your assessment. That body of people includes engineers, business people, and financial people (like I’ve recently become.)

Are you trying to tell us – with an apparently straight face – that Congresses decisions on VTR and fast reactors in general are somehow proof that they are not potentially viable machines.

The HTR-PM is the first of a kind, so I am not at all surprised that it would produce more expensive power than LWRs being built on a sustainable scale in China. But I am curious – where did you find detailed information on the program costs or on the planned scaling of the technology? Id like to review that information. HTR-PM interests me more than most nuclear technologies.

Finally, why do you assert that licensing a reactor requires unanimous approval? There is room for differing professional opinions without causing a denial. Even among commissioners, an approval can be issued without a unanimous vote. Vogtle’s COL was not unanimous, the vote was 4-1 with the chairman being the dissenting vote.

https://www.ans.org/news/article-934/nrc-issues-licenses-for-southerns-vogtle-project/

Michael Scarangella’s logic applies to the leisurely market of today. It won’t stay leisurely. In the climactic years ahead, there is a rising likelihood of a nuclear rollout worldwide. It is almost inevitable that the US take the lead in the mass production and export of at least one proven SMR. Certainly the first will be a LWR, and its rollout will stretch the current capacity of the world’s uranium mines and enrichment facilities. At the same time as the rollout takes off, the subsequent designs must already be being proven in prototype form, unimpeded by spurious restrictions. Increasingly constrained uranium supply is likely to dictate a subsequent wave of (fuel-efficient) fast neutron reactors, together with their associated reprocessing facilities. They too must be being proven in prototype form early in the rollout. In order to prove that they are market ready, all the above must have proving grounds where their last tweaks can be completed.

I didn’t do a good job of parsing through the word salad of your article. It was my fault and not that of the article.

It’s been a while since all these companies have pursued the various paths of alternative reactors to replace / augment the existing PWRs and BWRs in the US. Not much building seems to be happening. I’m not sure the complex regulations are aiding progress rather they may be abetting progress.

Perhaps its time for these companies to look at building prototypes / pilot plants in countries more friendly to the creation of this revised technology. It could be a peaceful South American country would welcome the infusion so this tech into their country. It could be a wonderful future export industry sure to bring in scads of needed revenue.

I think resources for Gen IV are spread too thin, at least given the current overhead for FOAK. Normally, having multiple companies working on each of the Gen IV technologies with their own specific designs would be a good thing, but given the requirement for at least some form of government support to get a prototype built, it might be necessary to collaborate on a single design. For example, all the companies with SFR designs should choose one design incorporating all the efficiency and economic innovations that each bring to the table. Same for steam cycle HTGR’s, Direct Brayton cycle HTGRs, MSR’s, and LFR’s. The cooperation should be on an international scale.

Vallecitos BWR was a prototype in its day. But that was built during the AEC (collaboration) vs NRC (regulation) paradigm. There was a distinct change in the industry when the government went from AEC to NRC. My earliest commercial mentors originally had AEC Licenses, plants named Elk River, Pathfinder, LaCrosse. These not far departures from prototypes.

US will not lead in nuclear energy because we – as a nation – do not have Atoms For Peace focus in DC. What we have in the Vogtle AP1000 example is the continuance of unstable regulation. The plant was was under an approved design and then was served with an Aircraft Impact Rule. Shield Building requirement over loaded the basemat, bring out the Civil Engineers and start all over.

The Aircraft Impact Rule was the clone of the *TMI Rule* imposed in the 80s under every plant then under construction. NUREG 0737 / suspend construction and respond with design changes. This caused cancellations / budget overruns / and regulated utility deals such as Shoreham ( started / ascended to 25% / declared commercial / decommissioned) – almost no utilities dare build after that whipping. The guys who know aren’t all dead yet.

We had our day and the trip from 105 reactors down to 95 didn’t take that long. In countries that have government control of business on a (hard to imagine but it’s true) greater scale than the US will have a much easier time building innovative reactors. Chinese APs Haiyang / Sanmen, handily beat Vogtle coming on line – building a Chinesium version of a US design.

@Rob Brixey

The project you mention were not the kind of commercial prototypes I am suggesting.

As far as I know, none of them were built by teams that were fully committed to building and selling a series of virtually identical machines after they had completing the construction and testing of the first of a kind licensed through the NRC process as being identified as a prototype that had not yet proved that it had practical applications.

It would be important for the developing team to firmly rest its case on the legal requirements from the Atomic Energy Act and to ensure that a determination of practical value needs to be applied to each specific design with the consideration that customers need proof that the system works as claimed and that it can be built for approximately the claimed price within the expected schedule. Without those customer criteria being met, the system should not be considered to have proven its practical value as a commercial product.

I believe that the current regulations clearly encourage developers to build and test their commercial products rather than depend on models and simulations that are not easy to verify and validate. Even with small scale “prototypes” there are serious questions about scaling, especially in systems that depend on natural circulation for safety.