X-300 Blazing a Different Kind of Trail in Smaller Nuclear Reactor Development

GEH spent about half a billion dollars designing, testing and certifying the ESBWR. Despite that investment, the 1,520 MWe Enhanced, Simplified Boiling Water Reactor (ESBWR) design documents are just gathering dust with no active projects in sight.

GEH is a joint venture between US-based GE, a $95 billion annual revenue conglomerate and Hitachi, a Japanese technology leader that is in the same corporate weight class as GE.

Inside both companies, nuclear power is a relatively minor and often-neglected business unit.

A small, but growing group of people working at GEH believe they have found a way to extract value from the trove of already reviewed and approved ESBWR licensing documents. They know that the ESBWR design has many positive attributes, but the product packaging, size and marketing are not well suited to the current power and heat market.

GEH’s new X-300 power station design is a rethought and repackaged ESBWR. The company believes they have successfully addressed the factors that convinced customers the ESBWR wasn’t worth building.

On Monday, March 30, I spoke with David Sledzik, SVP Sales and Product Management at GE, to learn more about GEH’s X-300 development and deployment plans.

Utilities don’t want to be first in line

One hard lesson from the slow start of the Nuclear Renaissance is that utility companies – and competitive power generators that used to be utilities – do not want to be first. They are interested in building proven machines that can be delivered at a predictable price on a predictable schedule. They won’t buy incomplete designs anymore.

Neither corporate boards nor public utility commissions will approve the almost open ended investments that are an inevitable feature of FOAK projects.

The federal government created the Advanced Reactor Demonstration Program as a partial solution to the first mover avoidance problem. That program will help to fund construction of two demonstration projects that can be completed within five to seven years of the government’s final contract award.

The ARD program will require a significant matching investment from private company participants, but many believe the direct federal investment reduces the risk into the acceptable range.

Note: It is important to keep in mind that no one is promising that they will be able to complete a project by a certain date. The clock cannot start running until primary contracts are in place. No doubt there will be people who forget that fact when they begin criticizing and claiming missed deadlines

The financial boundaries of the ARD program encourage smaller projects.

GEH is part of a coalition of companies that will be responding to the DOE’s promised solicitation with a proposal that will include the first X-300 as the target demonstration technology.

5 times smaller version of already licensed design

The X-300 is fundamentally a smaller version of the ESBWR. That fact turns GEH’s investment in licensing the 5 times larger machine from a write off stored on a dusty shelf to something with real value.

Instead of starting a licensing review from scratch, GEH will submit licensing topical reports (LTR) that cover the differences between the X-300 and the ESBWR. These reports will allow the company to incorporate the previously approved features and analysis by reference, eliminating the need to do a full review.

That process started several months ago. On Jan 30, GEH announced that it had submitted the first LTR for the X-300 at the end of 2019.

Sledzik told me that the NRC expects a 12 month review cycle on each of the LTRs. Numerous reviews can be conducted in parallel.

The company has determined that the two step, Part 50 licensing process is better suited than the one step, Part 52 process to a first of a kind development project. Part 50 will enable earliest possible completion and operation. Part 50 licensing means that construction can be started after a preliminary safety analysis and a issuance of a construction permit.

Even though using Part 50 licensing, the company and its partners will carefully approach construction sequencing. They need to be confident that they will not be slowed by significant redesign or need to rebuild already completed portions of the plant.

Smaller plants are easier to cool

It’s almost trite to point out that smaller nuclear plants produce proportionally less decay heat. It’s also obvious that it’s easier to cool cores with a smaller number of traditional fuel assemblies.

Based on design calculations and model simulations, GEH believes that the X-300 design can passively cool itself for at least 7 days without any external power or need for operator intervention.

Smaller plants are easier to build

Conventional engineering scaling laws say that cost per unit of output power should increase for a smaller unit. But those scaling laws do not recognize the importance of packaging costs.

As part of its design-to cost effort for the X-300, GEH has found a way to shrink the total size of the power plant – including buildings and supporting systems – by 90% when compared to the ESBWR. Even with a power output reduction of 80%, the result is that X-300 uses half as much material per unit power.

Using safety grade concrete as a useful comparison metric, the 1520 MWe ESBWR needs ~100 m^3/MWe; the 300 MWe needs ~50 m^3/MWe.

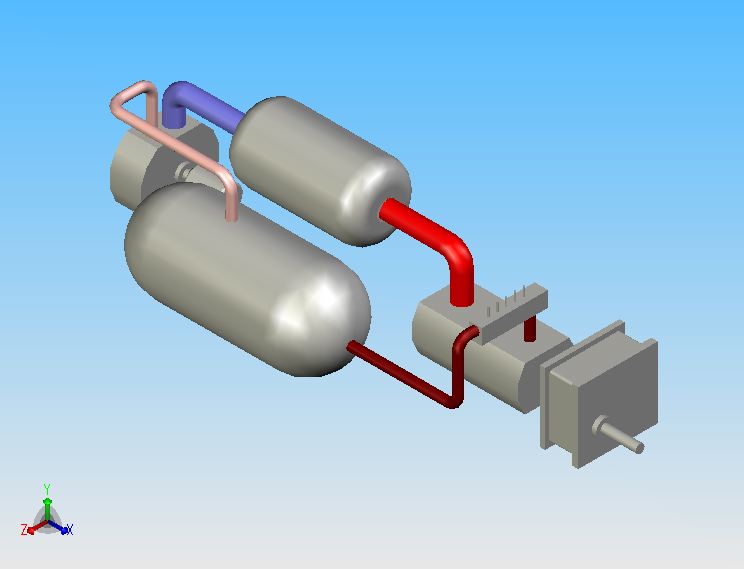

Another construction advantage of a smaller reactor core and the associated narrower containment structure is that the resulting system dimensionally fits within the capability of tunnel boring equipment.

Compared to traditional excavation techniques, tunnel boring machines can substantially reduce the time required to create the 40 meter deep hole that will house the reactor and containment portion of the X-300.

Advanced construction techniques will enable the containment structure to be assembled above ground and then sunk into the hole created by the boring machines. A significant design and testing effort is required to convince regulators that the containment system can be properly inspected both before installation and throughout the life of the reactor plant.

One advantage that GEH has over many of its competitors in the business of building smaller nuclear plants is that it is part of a conglomerate with a large steam turbine and generator division. GE’s steam power plant unit has deployed approximately 200 turbine generator sets that are virtually identical to the 300 MWe sets that will be paired with the X-300 reactor steam supply system.

Utilities are interested and investing

Though no utility has made a commitment to build an X-300, at least one utility, Dominion, has publicly announced that it is investing and participating in the X-300 development.

I spoke to Dan Stoddard, Dominion’s Chief Nuclear Officer, on Tuesday, March 31. Though he was careful to remind me that Dominion does not have any plans to build an X-300, he explained why his company was interested enough to make some “modest” investments in the technology development.

Dominion is committed to steadily reducing CO2 emissions. The company has recognized and is taking advantage of the steep cost reductions in solar power systems, but it believes there are limits to the total amount of solar power their system can accommodate while maintaining system reliability.

He acknowledged the fact that there is great enthusiasm about energy storage, but reminded me that 4 hours of storage is far from the amount needed to cover routine nighttime demands. When it comes to seasonal variations in solar power, existing forms of storage cannot begin to cope with addressing the challenge within any kind of reasonable cost.

So Dominion believes that nuclear energy is necessary to achieve CO2 emission goals, but the company isn’t interested in taking a “bet the company” risk. If expectations can be achieved, the X-300 appears to be a good fit for needs that will begin to rapidly grow in the late 2020s through the 2050s.

The projected cost of the plant – perhaps $700 M for a 300 MWe Nth of a kind unit – fits within the normal financial capability of the company. (That number is computed from company’s announced target of $2,250/kWe with a margin for error and using a more appropriate, single-significant-digit precision.)

The moderate power output means that it would be possible for the company to build several follow-on units on the same site without overwhelming transmission systems or causing major system bottlenecks.

Despite its history of increasing costs, the nuclear industry has successfully lowered costs for succeeding units on the same site. Project managers learn to improve scheduling efficiency, workers learn their jobs, permitting challenges smooth out, and supply chains strengthen. Even Plant Vogtle, no one’s shining example of excellent cost and schedule performance, has demonstrated significant improvement between unit 3 and unit 4.

Stoddard indicated that Dominion wasn’t the only utility interested and involved in the X-300. He wasn’t willing or able to name others or to give me any hints on which sites are under consideration to be the place where the DOE-sponsored demonstration will be built.

Bottom line is that GEH’s X-300 is a formidable competitive entrant into the smaller reactor field. If the company fully supports the project with its considerable financial and political heft, the product could be a resounding success.

GEH will have to stop using the inflated priceing policy that they use whwn selling parts mto operating Nuclear Plants.

1500MWe ESBWR planned to have 1,132 fuel assemblies and ~38′ core diameter per:

https://nuclear.gepower.com/content/dam/gepower-nuclear/global/en_US/documents/ESBWR_General%20Description%20Book.pdf

Using scaling, and making a sketch, it seems like BWRX-300 would have ~224 fuel assemblies with maybe 45 control cells (4 fuel assemblies around a control rod). Nice! that core would be at least 8′ across making BWRX an SMR with fuel economy approaching what we see in the current LWR fleet. So, the BWRX-300 gets my vote as the preferred of all the proposed SMR technology including NuScale. Natural circulation actually makes sense in BWR.

Still, I pick ABWR over ESBWR because ESBWR gives up the ability to rapidly run-back thermal power by reducing forced convection (re-circulation). ESBWR/BWRX-300 propose modulating feedwater temperature to maintain desired power level between scheduled control rod pattern adjustments. The various recirculation run-backs save a trip every year at plant X. The alternative could be high capacity turbine bypass to a larger condenser?

GE has a history of selling BWR of whatever vintage in variable diameter; Duane Arnold is about half the diameter of Susquehanna and they are both BWR4.

The ESBWR and BWRX-300 ARE the future of nuclear – no problem with MOX – 50GWD/T discharge exposure easy. Things have gotten more simple with the fine motion control rods and the natural circulation. GE makes amazing machines!

@michael scarangello

Interesting analysis.

This phrase confuses me because it seems out of place in the context of your general approval “Still, I pick ABWR over ESBWR…”

[I can only imagine] There are reasons GE offers both ABWR and ESBWR. The individuals briefly involved in scoping the Wylfa Newydd site in Wales, which unfortunately will not be built, seem to agree that the ABWR might still be the better product. ESBWR gives up a major reactivity control knob (modulating forced convection), ABWR implements what appears to be the ultimate solution to forced convection, under-vessel mounted recirculation pumps. Side note: word is ABWR capacity factor in Japan did not match earlier models prior to the Tsunami – perhaps still in shakedown.

One additional concept to noodle on: I do not agree with the people that find the incremental approach to nuclear plant design to be flawed. These individuals often say something akin to: “We need to revolutionize the industry with adoption of technology X <>.” The lineage of the BWR stretches back through 6 types that have been built (BWR2/3/4/5/6/A) and projects 1 type that is approved and ready to go (ES) and a further derivative (X) that will not require NuScale-like effort to approve. The lineage stretches back even farther to the BORAX experiments conducted by INL and supported by GE as primary contractor. The incremental evolution of the BWR parallels the incremental evolution of the passenger jet, 707 (BWR2) to A380 (ESBWR). Note that Airbus can’t seem to sell A380s just like GE can’t sell ESBWRs – still Boeing continues to sell the 747 (ABWR). Fly on a 777 and it is not just a dressed-up 757 with WiFi; it is lighter, has more fuel efficient engines, better range – all around better – but still fundamentally the same. Most people (Musk aside) dismiss the revolutionary ideas of Mach2 travel (Concorde = BN600) as simply not worth the risk to operate below the subsonic jet’s economic margins. I digress. Let me assert: we only make good machines after an incremental approach. As Jigar said, we make good cars because we have made millions of them.

I think that Michael means that, since the ABWR is still using forced convection, it has direct control over that convection, whereas the newer designs use temperature, which is a more difficult and subtle way of trying to control the same thing.

Correction: ESBWR is 38 fuel assemblies across, which would be about 19′ across. Apologies

BWRX-390 of 19’ is a 5.8m core diameter. To meet the definition used of ‘Small’ for reactor size, as opposed to ‘Small’ reactor electrical power out commonly used, means road shippable which means a max of 4.25m, 4m practical for long items, reactor vessel including full circumference flanges.

Aside: As far as power output, small is better defined as thermal power, not electrical power because both decay heat and releasable radioactive source term is proportiinal to thermal power and fuel average burnup, not electrical power.

https://1.bp.blogspot.com/-qMGB8y7IEzw/Xo4YmWsuWLI/AAAAAAAACd0/towrbcjXbII-PFz6RldPzTcvutx9ZztwgCLcBGAsYHQ/s1600/Cross%2BSection%2Bof%2BShaft%2Band%2BReactor%2BEquipment.jpg

TVA is to use Clinch River site as a location for an SMR demonstration. As TVA shows no interest in the Nuscale modules, expect this GEH unit as a more modest demonstrator.

My guess.

I agree Clinch River is a more likely site. Clinch River ESP is for up to 700 or 800MWe total, and already has three sites evaluated for SMR LWRs, not just one. Clinch River will also accept Advanced Reactors, i.e., non-LWR, but any delta to the LWR SMR ESP would be needed

This is amusing, because if I recall correctly, the ESBWR was a result of increasing the size and power level of concepts that were originally developed for GE’s SBWR (Simplified Boiling Water Reactor), until the design reached viable economies of scale. (The “E” in ESBWR stands for “Economic.”)

It’s the same process that resulted in Westinghouse’s AP-1000, which is a bigger cousin of the older AP-600 design. The same thing happened with modular gas-cooled reactors (which I work with) as well: the designers start with a small, modest power level that they know can be easy to cool, and then push the limits to make it bigger and bigger, until the limits of inherent or passive safety are reached.

That is a point that I was trying to make in a recent post here. Yes, small plants greatly reduce the complexity, analysis, and regulatory requirements to ensure that the reactor will not overheat. It also makes the economics more challenging, however.

It is not surprising that Dominion is participating in the X-300 development. They have long been interested in putting an ESBWR at their North Anna site, but they have never committed to it. Legislation that was passed earlier this year in Virginia might further spur Dominion’s enthusiasm for this design. Power bills will be going up across the state.

Actually, in all other ‘small’ designs except microreactors, the complexities appear to increase significantly compared to ABWR/ESBWR. However, BWRX-300 is vastly simplified compared to ESBWR, in contrast with other SMRs because the basic BWR RPV design hasn’t been redesigned.

The irony of this being in contrast to the trend of economy of scale isn’t lost on me, but it’s key to recognize it’s the simplification from avoiding the loss-of-coolant accident that enables BWRX-300’s scale and cost reduction, not its mere output size reduction or total power of its shutdown cooling needs.

Excellent high level review of BWRX-300. I fully support BWRX-300 as the most economic LWR SMR. I have even volunteered to help them to get all cooling systems to non-electrical pumping capability as long as there is heat or decay heat > 90C. Also, to extend the passive non-electrical cooling capability to indefinite time as long as water is near by.

But, since it is still just another rendition of LWR, AND soecifically a derivative of an existing licenses design, does it meet the definition to qualify for the ADVANCED REACTOR Demonstration Program by Congress and the DOE-NE?

BWRX-300 is a dramatic simplification of ESBWR – enabled by designing away the loss-of-coolant accident, the zenith goal of any advanced reactor.

P.S. And by DOE’s revised definition, any reactor that hasn’t been built basically qualifies as an Advanced Reactor.

There is one massive point missed out from this article, openly stated by Glen Watford, at 47:50, in this video, and that is the 2 year build period. This is the same as any of our low-carbon electricity generating enemies – the renewable technologies.

It means, the cost-of-capital torture nuclear has had to bear for decades, in this competition, is negated. In the UK, the £587 million capital cost of an NOAK BWRX-300 would would generate 142 million MWh of dividend-paying earnings. £587 million is the capital cost of 527 MW of onshore wind in the UK and that is by far the most cost effective renewable technology. That amount of onshore wind would generate just 31 million MWh.

Fund managers will be clawing at one another’s throats to get their pension-pot money out of renewables and into the BWRX-300. That exercise in futility so many nuclear supporters advocate – educating the general public – will evapourate. Investment will flow in; politics will follow the money; the 99.99% of the general public – those utterly indifferent to where their energy comes from – will shrug their shoulders and say “just get on with it”:

https://www.youtube.com/watch?v=sH026hXti0U

Where’d you get them rose colored (or coloured) glasses? We should mass produce them like N95 masks and hand sanitizer and distribute to the public free of charge.

Too damn long for something without a worthwhile description. Will not bother to watch it.

How about the siting of this or any of the new nuclear technologies? I remember when I worked at a BWR 3 years ago and read the FSAR that the plant had to be located 40 miles from a major metropolitan area?

Will the same or similar restriction apply to these new plant? I’m not sure about a unit with 7 days of passive cooling like this one , but it seems as though the units that are passively cooled period, could be sited easier. There are a lot of coal and nuclear plants that have been shut down. It seems like there would be quite an advantage for one of these plants to take advantage of existing sites. A new site would require new substations and transmission lines which can be quite costly.

The same basic idea applies to the security investment. Would the new units require an army of security people, several manned security stations for the sophisticated security apparatus, sirens and evacuation drills and giant rocks (BFRs) around these plants or a more sensible approach?