South Texas Project Unit 1 tripped at 0537 on Feb 15, 2021

Update: South Texas Project Unit 1 started up during the afternoon of Feb 17. Vicki Rowland, lead for internal communications at STP Nuclear Operating Company, stated that the plant was connected to the grid at 2107 (9:07 pm central time). It began a steady ascent to 100% power.

The NRC’s Power Reactor Status Report for Feb 18, 2021 reported that South Texas 1 was operating at 36% power. Congratulations to the skilled, hard-working people who restored that important power source. End Update.

A series of winter storms and a blast of Arctic air has put most of the United States into a short term energy supply challenge.

Texas has been the epicenter of the winter event. Its electric power grid has been under an Emergency Energy Alert Stage 3 since the early morning hours of February 15. At that stage, reserve margins are so tight that the grid operator has issued orders to transmission companies to reduce loads on the system.

The transmission companies have few remaining tools available to keep the grid in balance and prevent widespread collapse. They have reached the response stage where they need to implement rotating outages. In some cases, the margin between reserve generating capacity and demand has been so tight that the rotating outages have been substantially longer than the typical planned duration of 15-45 minutes.

There are numerous contributing factors, including fuel-related outages at natural gas fired power stations, a lack of wind as the cold air settles in, freezing at some wind turbine generators, and challenges at coal plants.

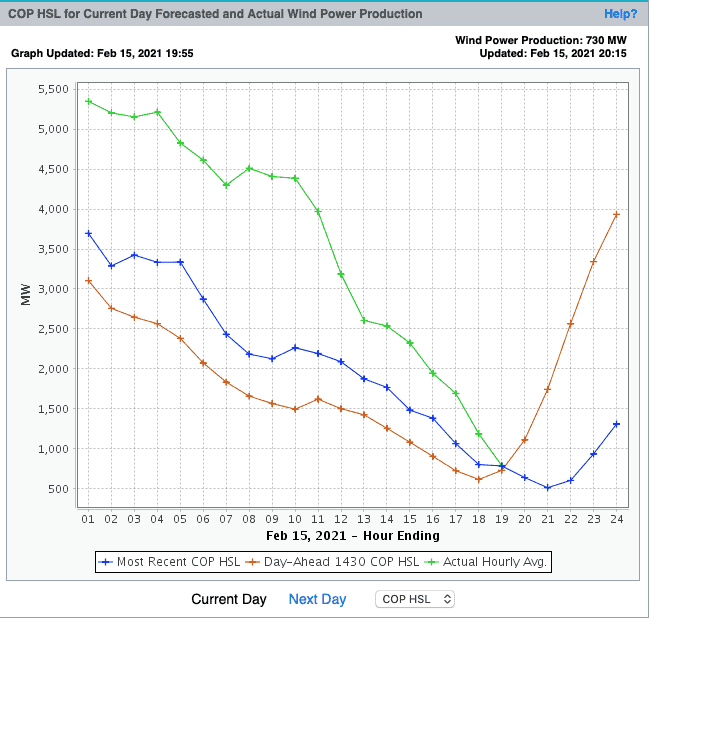

Approximately 35 GWe of installed thermal generating capacity was not producing electricity for a significant portion of the day on Feb 15. As of this moment, 8:15 PM central time, there is no solar electricity being provided in Texas and its 30,000 MWe of installed wind turbines is generating just 800 MWe.

Note: The link to Ercot’s wind generation graph leads to a dynamically updated page, so the image here is for a specific moment in time.

In addition to those other electricity supply system issues, at 0537 central time, there was an unscheduled trip at South Texas Project Unit 1. That nuclear generating plant usually produces 1350 MW of electricity.

Vicki Rowland, the lead for Internal Communications at the STP Nuclear Operating Company provided the following narrative about the unit’s operating status.

On Monday, Feb. 15, 2021, at 0537, an automatic reactor trip occurred at South Texas Project in Unit 1. The trip resulted from a loss of feedwater attributed to a cold weather-related failure of a pressure sensing lines to the feedwater pumps, causing a false signal, which in turn, caused the feedwater pump to trip. This event occurred in the secondary side of the plant (non-nuclear part of the unit). The reactor trip was a result of the feedwater pump trips. The primary side of the plant (nuclear side) is safe and secured.

STP values safety over production, so our first priority is the safety of our teammates, especially regarding the freezing weather and road conditions.

Secondarily our priority is the operating unit. Unit 2 is operating at 100 percent power. We evaluated Unit 2 and have confirmed that we do not have the same issues that caused the feedwater pump trips in Unit 1.

STP crew members are safely working to promptly return Unit 1 to the grid. We are validating the issues that caused the feedwater pumps to trip and will take the necessary actions to prevent reoccurrence.

STP has operated very reliably with only two reactor trips in the past several years. On May 1, 2016, the South Texas Project Unit 1 automatic reactor trip due to a main generator lock. Prior to that on Jan. 8, 2013, Unit 2 experienced an automatic reactor trip from full power caused by a main transformer fire.

If you have any questions, please contact me directly.

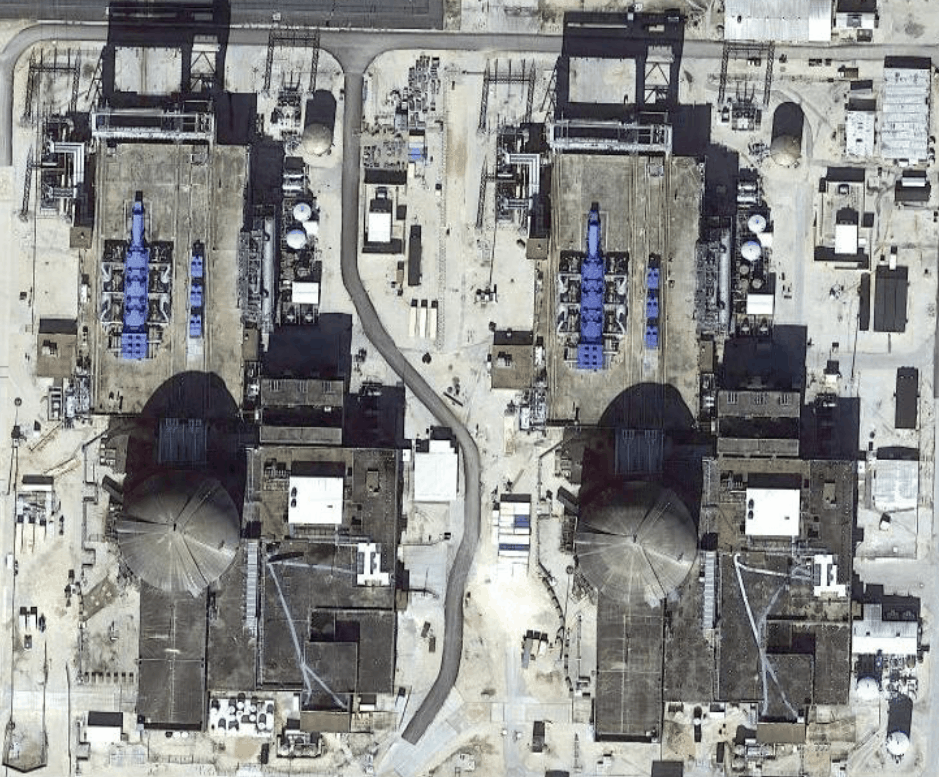

Update: (Feb 16, 2021 1345) Some people have wondered how “pressure sensing lines” for a feed water pump could have been affected by cold outside air temperatures. There are no turbine halls at STP, both of steam turbines are out in the open air. I’m sure there is a design reason for this choice, but it isn’t apparent. Here is a satellite photo of the site from Google Maps. End Update

I respect nuclear plant operators and believe in the importance of the industry’s safety culture.

But, I hope that this event becomes a topic of discussion about the balance between operating – or not operating – nuclear plants with the utmost caution and the occasional need to recognize the life-sustaining nature of reliable electricity.

The submarine force has protocols in place that recognize the need to balance safety of the nuclear propulsion plant with the safety of the ship that it propels. During my tour as Engineer Officer I ensured that my crew knew that a perfectly safe reactor at the bottom of the ocean in a sunk ship is not perfectly safe.

Though the Texas grid is not going to sink into the ocean, there is a point at which an over abundance of caution can turn into a harmful course of action.

I know I am being finicky, but this comparison does not put the correct perspective since you switched from GW to MW…

“30 GWe of installed wind turbines is generating just 800 MWe.“

How about writing it as 30GW and 0.8GW, or 30000MW and 800MW, to emphasize the order of magnitude of the failure of wind energy?

That would be clearer to read, IMHO

Thanks, Luca

Agreed. Change made

Rod, this problem suffered by the Unit 1 reactor at South Texas is not uncommon for nuclear plants in the south apparently. The secondaries are simply not designed to withstand cold weather. I spent one horrible night as the reactor operator at the old Robinson plant near Hartsville, SC when it got down to 11º above zero. It was like playing Russian roulette all night long due to freezing sensing lines. We kept the plant operating but just by a thread and came close to losing the battle many times. I sympathize with those Texas operators.

That problem should be addressed in plant design!

I hate being pedantic but you’re entirely right. It’s very important to not mix up units, within a single source and certainly not within a single point.

The general public doesn’t read suffixes. Human thinking is just big number little number.

I’ve noticed a LOT of radiation safety cards make this mistakes. They start in microsievert and then switch to milisievert. The results being that a normal (not stupid) person reading normally sees numbers that jump up by a very small margin as they’re only looking at the column of numbers. And they react quite rationally to that misconception by running from anything radioactive. It’s the same here but in reverse, 800MW sounds like a lot, when it’s really not.

Alternatively writing 30,000 MW of capacity would help avoid a decimal point. Which is also a laudable goal when talking to normal people.

What’s even worse is switching from sieverts to rads. It’s easy enough to lookup on line but it slows up reading.

The installed capacity of wind was not forecasted to be on at this time of year. It is misleading to call the difference in installed capacity to generating capacity a failure. In addition, ERCOT’s winter plan published in November already took into account total loss of wind as a contingency. It did not contemplate the loss of 35 GW of thermal generation.

I agree completely with this, although I’m a nuclear engineer (most recently Vogtle 1-2). Some Southern plants have turbine buildings, like Vogtle 1-2. Many other plants in the deep south don’t, nuclear, fossil, gas and even ones like wind and solar. Buildings cost money to construct and the emphasis on cheap construction has left off many traditional turbine as well as other buildings. Boilers benefit from a building to control temps and protect sootblowing equipment. About half Colorado’s plants lack boiler buildings, and a few lack turbine buildings as well. Us heavy metal dudes try to shift blame to the wind and solar folks, but they were never in the plan to serve this time of year. We were, so shame on us. Carla, you should take solace in the fact that by being unavailable for a week, STP lost around $75-200 million (Yes, that’s millions) in income. If their management boards don’t roast their operations people, they’re plain stupid.

Greetings,

I am not part of this forum. I am an historian that wrote my dissertation on the South Texas Nuclear Project. I am presenting a paper in a few weeks on the winter storm, and I am curious about evidence about comparisons to other plants. Lots of comments in this thread about winterization of nuclear plants or lack thereof. I was wondering if somebody would be interested in chatting via email or otherwise. Mr. August, your posts caught my eye in particular.

Warmest regards,

Joseph Stromberg

I’d also argue including:

* How much natural gas production was reduced (https://www.naturalgasintel.com/no-easy-answers-as-texas-power-grid-natural-gas-market-rocked-by-unprecedented-cold-snap/)

* Maybe a brief mention of the failure of the wind energy / natural gas / STP was not having enough winterization. (common in most other parts of the country)

There is a *LOT* of politically motivated misinformation flying around. No one source of energy was at fault. Failures due to lack of winterization applied to pretty much every energy source in Texas.

We have good data on what the “worst offenders” are now… lets act on that and improve things.

With all due respect, we’ve had “good data” on the “worst offenders” for decades. Smaller and less publicized events, in less politically important states, have occurred regularly, People like Rod and I have been warning about such an event for at least the 20 years, although I had to pretty much give up the red flag waving due to ill health. I’ll admit, though, that, when I was in the thick of it, I wouldn’t have guessed TEXAS would be the head turner.

Without coherent energy policy, energy markets has been hopelessly distorted by political motivations. We do not evaluate energy technologies by the same set of objective criteria to decide how best to deploy them and where. There are technical risks—however you want to define dangers to people and the environment—for every energy technology. There are also risks associated with a “do nothing” approach, and if we bind ourselves to a linear-no-threshold assumption when it comes to things like radiation dose. I posit we must do the same when it comes to probabilities and consequences related to access to and affordability of electricity.

If we consider how best to address technical risks, and agree that there is a role for government to play, it stands to reason that we want to ensure whatever regulatory burden we place on the designers, owners, and operators of energy technologies exceeds the risk. Then the question becomes, “under what scenarios and with how much margin?”

As individuals and as a society we evaluate and make such decisions all the time. And we know that ensuring we put our seatbelts on every time we drive our cars probably isn’t going to help us much if we habitually turn into oncoming traffic. Yet, if we compare the “regulatory burdens” we impose against the “technical risks,” that’s exactly what we’re doing with different energy technologies.

I’m glad to be living in a state with regulated utilities. Utility guides the politicians into prudent policy for reliable supply. In exchange, utility gets a modest return on its money. Some years they don’t do so good and other years they rake it in.

As a couple of other posts have stated you have to provide backup reserve. My understanding of Texas is the System Operator can not mandate any company to provide reserve capacity. Recipe for disaster.

System I am familiar with always keeps minimum rolling / spinning reserve equal to largest unit online for seamless pickup in event of unit trip. Additionally there are negotiated agreements with “neighbors” to provide additional capacity across inter-ties for a fixed rate, short period, to allow spinning up more capacity on home system. If our lights go out it should not be due to lack of generation.

I don’t like many government regulations but electric industry it seems to work OK> And at least I’ll never get a $10,000 electric bill because of “market pricing” during a short supply.

Such a thoughtful, reasonable response! Well put. As a plant engineer 45+ years, I earned that many years of hate for requiring everyone to restore serviced equipment with insulation, heat trace and other cold weather protective equipment. It’s like everything in a “do it now, get it done and go on” mentality industry. Thinking about the long term and “what ifs” is impossible in that culture. You could not begin to restore this stuff in a week with that much advance warning of cold weather. As a plant engineer everyone on site hates your guts for worrying about this stuff at the end of an outage, project, or other work activity. As much as I have to say it, the only solution I can see is to enforce some kind of penalty on those who fail to meet their contractual, legal demands. In my experience, that has NEVER happened. It’s always a bunch of finger pointing and “OMG, that was a one-in-ten-thousand years event, enough already.”

You can take some solace in the fact that some huge generators like STP who dropped lion off with 1500 MWe of generation for a week (read that as dropped 1.5 million Texas customers who needed them) lost somewhere between $75 million and $200 million in foregone income. If that doesn’t get their boards attention, well, they’re hopeless.

Good summary. However, the feedwater pump trip description mixes up singular and plural: “failure of a pressure sensing lines.” Was it one failure or several line/sensor failures? Many nuclear operators have performed single-point vulnerability studies of potential reactor/turbine trips, and I should think there is sufficient redundancy to prevent a single sensor failure from tripping the FW pumps. A common-cause failure event of multiple lines because of adverse weather is credible, too, in this situation.

The NRC event report says two feed water pumps tripped, which seems a little confusing.

https://www.nrc.gov/reading-rm/doc-collections/event-status/event/2021/20210216en.html#en55104

I am not familiar with these specific plants, but feedwater pumps are high maintenance items, so it is common practice to provide 2 or 3 x 50% pumps per unit.

Perhaps identical sensor lines on two adjacent pumps froze.

Without the detailed engineering report, which only they have, you have to fill in some gaps with inferences. Having worked on many similar or even virtually identical plants (Voglte 12) I will make a few guesses. There are multiple sensing lines for both the Feedwater and Condensate Pumps. With (probably) three Condensate pumps fully exposed to cold weather, I will guess the problems originated there, since that’s been my experience. A condensate upset will trip off the Feedpumps if not quickly corrected. Even there, it’s still a high risk (TMI started with Condensate pump trips). Altogether, with the logics, there are multiple sensing lines. Any lines plugging due to freezing will be a problem. Typically they are 1/8th to 3/8 tube, insulated (lagged) and heat traced for cold weather, outside. In cold weather, even inside turbine buildings, the pumps can be exposed from cold air blowing in open doors (often doors are blocked open for summer or even year around). Although single point vulnerability studies are done on the safety related portions of nuclear plants, these (at least the CPs) were outside that and probably not done. Even if they had been done, guess what? Cold weather is a common cause problem cutting across single point redundancies, so that wouldn’t have solved that problem. This is really a cultural thing. (Ever since Boeing blew the 737 MAX analyses out their collective b*tthole I’ve felt much better.) The real issue is maintenance and how people do and don’t do maintenance. It’s beyond the nuclear design of the plant, although it is configuration management. If the nuclear industry can’t manage this with their tones of money, who can? If the FW pumps were involved, I imagine it was due to a condensate upset signal. Their skids, even outside in ambient air, tend to be bloody warm and even hot, in cold weather. I would really need much more specific information to say much more. Designs, lines and specific responses. STC won’t reveal that. Still, they ought to be taking their managers and lead engineers to task over why they weren’t better prepared. After all, $200 million is $200 million.

… have performed single-point vulnerability studies of potential reactor/turbine trips, and I should think there is sufficient redundancy …

Saw a few “single point” reviews done. Often, overworked personnel with limited experience and insight were assigned. Good, smart people but experience, cynicism, and more time available makes a difference in the quality you get. Some things just missed and some things initially don’t look like a “single point” but 2 layers down you see the truth. Unfortunately you don’t usually get 2 layers down or take a second look UNTIL, you have a bad day at the ranch. Once saw a frozen sensing line in a room nobody suspected it could happen in (bad day at the ranch). Once a dual feed pump trip due to “single point” failure that hadn’t even made review lists (single point was a couple of layers down in the circuit, faulty design)

Yes, someone certainly missed that one. Most northern plants, of which several suffered similar trips due to freezing lines even within buildings, have pretty much addressed that issue many years ago. If they are well organized and lucky, maybe they can get back in 24 – 30 hours if everything lines up well for them.

I have seen two redundant pairs of level sensing lines freeze on a 355 mw gas/oil unit causing a trip in NYC on a 10° F nite. Maintenance left rolling door open for a truck delivery causing a draft across sensing lines. 20 minutes and 342 MW off system for 24 hours and boiler loss of aux steam. Today plant has Aux Boiler to keep building warmer … but it was undersized by engineers.

MFW Pps (or MFPs) are not typically “high maintenance” items except for outages. Many plants just have two pumps and run breaker-to-breaker for many cycles. STP may well have had redundant MFP sensors which is typical for newer plants and/or control system upgrades, but were the redundant sensors all mounted off one sensing line per pump? Quite an unfortunate situation, regardless. I was amazed the operators didn’t trip the unit when both MFPs tripped, as there typically is very little likelihood of maintaining the reactor critical, or “catching” a total MFW loss, even if the operators had been recently practicing the event on the simulator and a third MFW Pp is ready in standby.

Yes, the operators are expected to manually trip the reactor on loss of multiple MFWPs prior to the automatic SG low level trip set point. While a design basis event, loss of feedwater is a relatively harsh plant trip. One question to ask, is whether the plants were operating outside of their design in such cold conditions for such a period of time. The control grade Main feedwater system typically does not have redundant flow instruments that control feed water speed and the spg level control vale’s that operate typically 2 or three element control off SG level, Feedwater flow, and main steam flow. Naturally, you freeze one side of a feedwater sensing line, you are going to be screwed. Did the operators of STP and Comanche Peak operate their plants conservatively in such cold conditions.

Hi Rod – thanks for this summary. It’s worth stating that the Texas grid is a separate section of the national grid system and is pretty much fully deregulated. Also, more to your point, the other three reactors, two at the Comanche Peak plant as well as South Texas 2, have continued to operate. Together, these three represent a bit over 3 GWe actual generated. How many more people would be without power–or how much more challenged would the system be–if these had not been built?

Seems to me that this should never had happened instead of making the states surrounding texas pay for your incompetent protocols for extreme temperautre . This should never be a issue. Hell nuclear power is designed for demand of supply

Note the ERCOT graph – wind power is producing inline with ERCOT expectations and had over performed expectations prior to 1800.

The real question in my mind is why ERCOT gas/coal/nuclear power only appears to be dispatchable above 32F. Below freezing it is as much weather dependent as renewables.

Second question is if the gas transmission grid is sized for simultaneous peak gas demand for electrical generation and heating fuel.

NB ERCOT’s expectations were that 97% of installed wind capacity and zero% of solar capacity would not be available during the evening peak.

The good news was that wind did in fact provide its 3% of capacity.

I do not call 3% overperforming.

@John Bennetts

I think you meant to write 100% of solar would not be available during the evening peak. Or zero% is available.

As it turns out, wind energy was only minimally responsible for the shortfall. Gas and coal were the main culprits.

comment by James Smith contains one slight error. I can not speak for all nuke plants but I am aware of a couple that can “black start” and build a grid outward should the terrible day happen. Power supplied from Fossil fuel plant not required to make this happen.

Aaron, of the 90ish nuclear plants in the USA, how many of them tripped during this deep freeze? One? Please don’t group nuclear with coal and natural gas (fossil). Capacity factors for nuclear plants in the USA average >90%. That level of reliability is a pipe dream in the fossil power industry. Nuclear doesn’t get starved for fuel when gas, coal and oil are in short supply…they contain 1-1/2 to 2 years of fuel after each refueling outage, making them the most resilient source of electric power in the country.

…. in the USA average >90%. That level of reliability is a pipe dream in the fossil power industry. …..

Great comment. Little is known outside the industry about the progress made in nuclear production reliability. I started when the industry was still “young” and operating like a coal plant was the norm. Trip off and restart, no big deal. Since that time anything less than running breaker to breaker (refuel to refuel) has become less than stellar.

If STP is like where I worked they will have limited start up experience and this is a blessing that complicates overcoming machine personalities.

I fondly remember the parties sponsored by the company for significant firsts : continuous runs of 30 days, 6 months, breaker to breaker. now breaker to breaker is not a celebration but an expectation.

Most combined cycle gas turbine plants do have a capacity factor north of 90%. Try to do that with a nuclear plant while shutting down and starting up every day. 😉

Exactly! Green (wind/solar) has a capacity factor of 10 to 30%; fossil 40 to 60% and nukes at 90%. However, nukes require the grid to be up and operational – nukes cannot black start – therefore, fossil is very important to feed the grid. Wind and solar are not base load commodities and the idea of “going green” is nonsense – as noted by the comment above (800 of 30,000 Mwe); less than 3% operational. Side note – nukes are licensed by the NRC – not the state governor’s office. STP U1 will stay down until the Unit supervisor says it’s ok to bring it back up – not any politician –

You’ll notice the capacity factors of the fossil units are roughly the complement of the renewables. Probably because the fossil units are required to support the preferential treatment given to renewables.

Just a clarification, main feed pumps are not required for the safe shutdown of a plant and as such may not be required to have redundancy. Typically the loss of any main feed pump above a certain power level initiates an automatic reactor trip. It is the design to be ultra conservative with “safety” making it much easier to trip a nuclear power plant than it is to keep one operating at 100% when it is needed. The point is that an over abundance of caution for reactor safety concerns may actually have a negative impact on the health and safety of the public.

With all the danger caused by the weather and lack of electricity, how hard/long is the process to bring #1 back on line?

determine and correct cause 2-6 hours

perform required maintenance (if any) 2-24 hours

perform required testing prior to start up 1-12 hours

get permission to re-start 1-6 hours

re-start and produce electric 2-12 hours

I would evaluate all times as optimistic. Somewhat depends if anything broke as it shut down. Back on line in modern times is not likely to be less than 12 hours and could easily be 40 hours. Starting up requires skill and a little bit of luck.

Don’t know this plant, could start easily or could be one that doesn’t cooperate very well. Complex machine and design emphasis makes it harder to stay up than be shut down. Safety and all that.

(Former reactor operator and nuclear engineer here)

Don’t forget transient Xenon after a reactor trip from full power – will take several (or many, depending on how long they’ve been operating) hours until restart is possible, regardless of “fixing” the MFW pump pressure sensor issue.

I agree with FOWG RET’s timelines.

Commercial plants are like getting an elephant up, on its feet and walking again. One of the consequences resulting from the dramatic improvement in plant capacity factors since the 1980s, and the ever increasing number of “breaker to breaker” runs, is that REAL reactor and plant startups are . . . well “rare” isn’t the right word, but so uncommon that they are absolutely the most important thing on site that day. The NRC is VERY interested, as are all of the site staff groups other than Operations. I remember that our Operations group was determined to NOT put the “A” team or a team of “all stars” in the Control Room for a startup (as any licensed Shift Sup, CRS, and RO team SHOULD be able to perform it effortlessly), but my startups always seemed to have a few of the superstars lurking around, ready with “helpful suggestions!”

The post-trip review and analysis was always the most important pre restart piece. And that always seemed to be like evaluating the Challenger explosion. Plant management (which is now likely to be the top of the nuclear management group responsible for a number of reactors) has to be satisfied the cause is known, addressed, and corrected. And then presented to the NRC for review. As I recall, the precritical checkoff list was an inch thick. I believe that chunks of it could be “NA’d” if approach to criticality could begin within a certain timeframe post-trip. If memory serves, the absolute fastest I ever saw trip to commencing “pulling rods” was 8 hours? The whole thing seemed to me to be like pediatric neurosurgery involving the separation of twins conjoined at the head. For anyone who thinks commercial nuclear power is inherently “unsafe,” you should see what it takes to start one of these beasts. It is beyond cautious and careful and religious. It would make you feel a LOT better about what those operators are doing.

Many of us in Far West Texas have been without power for over 2 days now. When can we expect to have it restored? We’re freezing out here!

How’s that Ayn Rand working for you? 😉 😉

You guys are rugged individuals, right? Then quit complaining and read some more Ayn Rand and Reagan by daylight!

I find this comment very much out of touch.

What has Ayn Rand have anything to do with the power grid failure in Texas?

What is your knowledge of Ayn Rand, and why is it that you smearing her by proxy with a situation similar to what she was able to correctly forecast and write about in Atlas Shrugged as early as 1957?

What have you of her, and what have you studied?

I see you are smirking, but your disdain for one of the most amazing philosophers the world has seen, and surely the most influential one in the last 100 years, is pointless here.

Luca, a proud student of Objectivism

Ruth!

I get it. There WERE a few state government officials who suggested that Texans needed to “suck it up,” and that they were “willing to endure blackouts as the price to pay to preclude federal interference in Texas’ affairs!

But I did not see any one of those tone deaf officials reference Ayn Rand. Most of them don’t read! lol

When I looked at a picture of the South Texas Project, it appeared that the main turbine is on the roof of a building and the feedwater heaters are on the outside of the building on one side. But I couldn’t see any feedwater pumps. How do you know that the main feedwater pumps are outside instead of in the building?

Also, in climates similar to south Texas it is common for main turbines to be outside. At Rancho Seco, a B&W plant, not only was the main turbine outside, but safety equipment like the AFW pumps and CCW heat exchangers were outside instead of in an auxiliary building.

The three smaller enclosures to the right of the main turbine are the 3 feed water pumps. You can’t really tell from that picture but the pumps are just outside the smaller blue enclosures that house the feed pump turbines

Secondary plant is likely constructed same as one in Yankee country with the difference of not being inside a building. No turbine building equals cost reduction. Makes no sense to locate Feed pumps or other related equipment in remote building. Not sure I am right about this but have seen enough plants to suspect roughly standard construction practices and management desiring to cut costs. I don’t know if increased maintenance from equipment being exposed turned out to cost less than maintaining a building.

AFW + CCW outside, not on my list of have seen. Before my time.

A lot of the southern nuclear plants are like this. It was cost effective at the time of construction and the open air design is beneficial for the secondary side equipment during the hot seasons. I can’t imagine being on a turbine deck, in Texas, in August, INSIDE a building. Florida is the same way.

It was a cheap shot comparing military protocols to civilian protocols. In the civilian world public safety is first. When a trip occurs there is an evaluation to determine the cause, mitigate the cause and assure it is safe to restart operations. The crews work quickly to restore operations to full power. The process of restoration happens as quickly as technically possible.

Public safety is the key criteria. In an extreme weather event where people are at risk of freezing due to a lack of power from rotating power outages because there is insufficient electricity being supplied to the grid, isn’t the public safety evaluation shifted a little to the production side of the equation?

I GET the need for caution in nuclear plant operations, but I have a difficult time understanding how a frozen sensing line can lead to a shutdown lasting 30+ hours.

This should be something that is a topic of discussion among plant operators. What exactly, is the public being protected FROM?

Not to put too fine a point on the matter, I can’t see any other way to answer this question than this: the public is being protected from the nuclear fear that dictates such terrible things can conceivably happen at the plant that people must endure the sacrifice of power, basis for most areas of daily life (and health). Amen

… isn’t the public safety evaluation shifted a little to the production side of the equation?

Absolutely not. Safety is always about NUCLEAR SAFETY. When you forget that they put you in federal prison. Other forms of public safety responsibility lies elsewhere. I agree with poster who stated it’s not fair to compare protecting public safety from nuclear accident to saving a ship from sinking. Even saving a ship had rules attached, you could only go so far.

…but I have a difficult time understanding how a frozen sensing line can lead to a shutdown lasting 30+ hours.

Gone are the days of “latch and snatch” start ups. Regulators, INPO, etc. Once saw 3 starts in one 8 hour shift but that was many moons ago in a land far far away. Only time in recent memory I can remember trip to re-start under 24 hours is a trip provable to Operator error, last startup was less than 7 days ago, and nothing broke preventing startup.

This should be something that is a topic of discussion among plant operators.

The Operators in this statement is the management team who would have to spend money to find these kinds of problems AND / OR spend money to fix them when accidentally discovered. If you think it’s a problem but it’s never happened why should I spend money on it. Hindsight versus foresight. I’m guessing they will insulate a lot of stuff after this. If this happens again in ten years they will get their money back by not losing the generation they lost this time.

What exactly, is the public being protected FROM?

Can you say THREE MILE ISLAND?

Could be as simple an item is a lack of or not enough heat trace/freeze protection on the sensor line because nobody figured it could get so cold. Have seen this sort of thing at new combined-cycle units and took us a shift or so to figure out the problem and get sensor lines unfrozen (we used blow torches and portable heaters). Plants never really cooled down that much, so was sort of a running warm “start”. Really doubt such an rapid approach would work at a nuclear plant because of the paper work involved.

Inside or outside , nuclear or fossil fueled how can ANY type of line be so designed as it could freeze? I mean power plants have for sure 1 thing available HEAT and plenty of it how hard would it be to put enough heated pipe near or coaxial lines such nothing is at risk of freezing?? I mean safety in design texas may have little freezing weather but IT CAN HAPPEN! Means this place has inadequate design as there is a weakness in design that allows a possible fatal error ( fatal as in power plant unable to make power!)

In my experience (commercial bwr sro). You need to do the post transient review and ensure everything worked as intended. Stabilize in hot standby. In this case reset the isolations that occurred and get aux feed in standby. Test the shutdown nuclear instrument trips (since those tests are expired). Exercise control rods. Perform just in time startup training (remember these guys haven’t had a scram in several years and probably only a few have even done a shutdown or startup).

Gotta remember rod in commercial most operators never see a scram. I’ve done many shutdowns and startups because I’m good at them, at the expense of my colleagues barely getting any, but most of the SROs at my station have never done it. We just aren’t proficient. So everything goes a lot slower. Takes a lot longer. Last scram we had we took a level 2 water level isolation and it took almost 2 days to get the conditioners set up to bring the reactor coolant pumps back in service (I was on medical hold and couldn’t take the watch, and we haven’t had a level 2 isolation or been in natural circulation in over 20 years….maybe more).

Fastest I’ve done is 12 hours from commencing pull to crit to generator online and ready to enter the high power operating region and I’m considered one of our best.

It’s not all about being super safe. The proficiency isn’t there and nobody wants to fuck up and end up offline for longer.

Bwr sro for 6 years.

@Michael Antonelli

Thank you for your clear and well-informed comment.

For relatively obvious reasons, I won’t provide any details about my 30 year out of date experience operating nuclear submarines and running drills in preparation for Operational Reactor Safeguards exams. Suffice it to say that my operators became extremely proficient in recovering the plant after scrams. Convert your hours to minutes.

Rod;

You have a strong point with respect to balancing the need for power during emergencies against the endless dictates of safety in commercial nuclear power. But this has been an issue in the commercial field for decades. I was a CRS when our unit was knocked off line by a transmission line failure during a storm when power restoration was critical. We were definitely “advised” that restart was vitally important, and time was of the essence, but we were NOT to short circuit anything. Just to “expedite.” It’s a tough balance to be sure. But given the sensitivity of the plant’s design protective features, a control room team that pushes too fast on a complicated procedure (restart) that is NOW (given the incredible current day capacity factors and breaker to breaker runs) seldom performed other than in the simulator, not only risks missing something the NRC catches on review, but actually could pick up a reactor trip during restart. THAT would be like the worst day ever for a control room team and probably occasion a prompt search for another career.

It is very different for the military for obvious reasons. I was on a nuke carrier when Naval Reactors approved a “fast recovery startup” for surface ships. Rickover had a very fast recovery startup procedure for subs for obvious reasons, but had never approved anything similar for surface ships as he considered overall safety to outweigh the risk of loss of steam on a surface ship (all of which had at least two reactors anyway). But his successor viewed the balance a little differently, and we did get a fast recovery startup procedure (albeit significantly slower reactor startup rate limit than the subs). For better or worse, I took it as PPOW the very next ORSE. Nailed it completely by luck, but probably helped that we were the first ones to get tested on it, so the ORSE team probably didn’t have a good baseline for evaluation?

The level of caution you’re proposing is on par with not allowing airplanes to leave the ground for fear of a crash. Every action has risk and we must take the best balance of choices. The loss of that reactor is undoubtedly causing more harm than whatever tripped it (falsely) was meant to protect us from.

That the system can even do that is a good example of how overbuilt and hair trigger our nuclear safety systems are.

Consider the Apollo program, it was one of the most dangerous human endeavors ever, far more so than anything a modern commercial nuclear power plant might do. And safety was engineered into it at every stage as a top priority. In particular at launch; as a Saturn V rocket can explode with a force on par to a small nuclear blast, and it’s a hazard ANY rocket is prone to from time to time.

This intrinsic issue was handled with an escape system able to react in the fractions of a second needed to avoid that hazard and carry the astronauts clear. Yet, even with that huge risk to the valuable astronauts in which instant decision making is needed the Saturn V flight computer required TWO sensors to break before it fired the launch escape system. Only one sensor would result in a blinking light on a few control panels.

So why not use something similar to that in the much safer and slower confines of a nuclear reactor. Instead of EVERY single causing a trip, just signal the operators, perhaps with something shrill that needs to be addressed within a small time frame.

Fact is it’s really only necessary for the plant systems to trip for certain obvious hazards, lack of operator input, or many combined signals. Our current level of safety is just overkill and likely to cause more harm than good. Even without the current threat of freezing temperatures all the pointless reactor trips over the last few decades have added up to a lot of operating weeks for natural gas plants and that air pollution isn’t nothing.

I’m not sure I was proposing a level of caution as much as I was stating the way things exist. I think some common sense left the building long ago and was replaced with some clutter in the name of “safety”.

I agree the loss of the reactor under these circumstances is tragic but the loss of this single plant is a small portion of the problem. Their grid fell apart for a variety of reasons. Extreme weather, loss of wind generation, no solar generation at night, gas fired off line for lack of fuel, 1 of 2 nuclear off line due to protection system.

The initial problem was a false problem that took out the boiler feed pumps but low boiler level due to loss of feed was a real casualty worthy of reactor trip. I am generally in agreement a competent crew should be able to start under less stringent conditions but it’s hard to turn back policy once established. Even bad policy.

I agree nuclear power plant safety systems are hair trigger. That’s not all bad.

Your desire of multiple inputs to create safety system actuation is valid. Nuclear safety systems do use multiple inputs to create trip signals.

nuclear plant safety inputs typically are one sensor creates Warning alarm and status light. Multiple inputs required for actuation. Much effort has gone into eliminating any single failure trip. Probably haven’t corrected all of them but there are fewer today than there were 20 years ago. Much effort across the industry with information sharing to eliminate single failure trips. Operating companies want to eliminate lack of reliability. Can’t sell electricity if you are not making any.

…only necessary for the plant systems to trip for certain obvious hazards, lack of operator input, or many combined signals. Our current level of safety is just overkill …

Current design is mostly as your stated desire. Operating procedures and regulations have gone into areas not imagined and IMHO should be dialed back making re-starts less difficult.

I agree with the sentiment expressed by FOWget here, the idea is that this is completely foreseeable and application of risk management practices available at the time of construction should have and likely did lead to this being identified as a possibility and a choice was made not to address it through prevention due to short run cost

You have a point, however – the problem with nuclear stations is that once things went real bad – you can do nothig, only look from the distance when it all would end.

Remember Fukushima, 3 halted reactors blasted one after another with few hours gap and there was n-o-t-h-i-n-g people could do, just watch form distance.

Do you know geometric sequences, exponential functions? Can you grasp an idea of geometric functions with THOUSAND iteration persecond, in other word whatever neutrons multiplier there is – it gets raised to the power of 1000 every second.

You don’t like security systems running on hair trigger. The thing is, NPP itself is running on hair trigger. When Chernobyl halting system malfanctioned and instead of halting sent the reactor to the moon – it took four seconds and a half from 20% capacity operation to total devastation. Four seconds and a half. From 20% power to bomb-like all-out blast.

You just do not have time to drink a cup of coffee and think the situation through. You would not have time to even pour that coffee.

Actually, Chernobyl designers were optimistic, like mankind was 50 years ago. They hated the hair-trigger SCRAM systems with passion. And they were hell-bent to outcompete competitos of VVER house and make RMBK most cost-efficient design. They did number of things which looked reasonable then, and look damned today. And they made the permissive sefaety system, too. The system indded tried to range different malfunction systems and instead of unconditionally SCRAMming the place – to guess the mostly safe power rate and to slow down reactor to that reduced rate where it will – while malfunctioning – would keep operating at limited speed, until repair team arrives.

Back then it looked reasonable, with all the massive experience drawn from charcoal and gas power stations and water dams. And it made Chernobyl a celebrity of NPPs too.

Rod the gas plants used to have oil backups at most gas plants 45 years ago for times when the gas supply is shut off. I recall Austin burning oil for a month in the 1970s during a cold snap. This drove us to invest in coal and nuclear to diversify away from gas. So those oil tanks were not used much and the market competition could not support their costs so the oil tanks have been removed except maybe for a few small black start units. The new high efficiency gas plants don’t have oil backups. So this is the short term solution is to put some oil tanks at plants that can burn oil. We are in a situation where wind solar and gas are not dependable in cold weather. I suggested to the ERCOT CEO to tell the legislature that their staff can design in more reliability but not under the current market rules. The rules need to be changed. Our problem arises because there was not an appreciation for grid reliability in the power supply which the ruled prohibit the ERCOT staff from taking corrective design actions even if they see a problem such as paying RMR reliability must run generators more money to stay on line instead of closing shop. The legislature has come down hard on the ERCOT staff to leave the market alone and they did. This is the result of legislative actions, not the ERCOT operation.

I can testify that the oil tanks at the Handley gas-fired steam station in east Fort Worth were removed a decade ago.

Under the “competitive market”, the generating companies aren’t on the hook for guaranteeing adequacy of supply (if anyone is), so why should they bother with such provisions? Gas turbine plants, of course, can’t burn residual oil to begin with (it eats the blades). In addition to auxiliary combustors, they’d need a tank of Jet A.

And then there’s the fact that “cheap gas” is interruptible gas. The firm-delivery customers are mostly taking close to their maximum right now, so pipeline pressure is low, & there’s not much available for the interruptible customers.

That’s pretty sad generating companies are under no obligation to ensure adequate supply. The grid operator can only deal with what is available. Citizens should raise hell with elected officials who created that mess. Sounds like everyone can shrug and claim NOT my fault boss.

Are generating companies interruptible customers on the gas line??

Also, in what was foreseen ad a potential big problem years ago, gas pipes began deprecating the old but reliable piston compressors, which took their fuel right from the pipe, snd have been replacing them with ultra-high power electric turbine compressors dependent on electric power.

No electricity, no pressure. No pressure, no electricity generated at the gas-fired plants.

I’d bet a house this is happening right now.

Eugene, you are absolutely correct.

I worked at South Texas Project decades ago, from startup into early 2000’s. In those days

we had conservatively managed, outright stodgy UTILITY companies who OWNED and

managed the power grids in their territories of operation. Utilities had LARGE quantities

of spinning reserves, ready to replace any unit which might trip during hours of significant demand.

Texas’ deregulation did away with those integrated utility companies, making it an ‘every man for himself’ contest to generate and sell into the Tx market. The grid operator, ERCOT, can REQUEST that some generation operate as reserve, but they cannot COMPEL anything like that. MANY electric consumers have signed contracts to buy from Wind and Solar generation sources, resulting in Billions of $$ invested in these ‘renewable’ sources (but NOT in Grid security and reliability). Now those ‘renewables’ have been virtually useless in this weather-challenged season. Sometimes we get what we pay for.

Yes Peter but the turbines can be retrofit weatherized. The old power plants are a different story. We could be looking at BILLIONS to bring these up-to-date.

Per ERCOT’s statements today, the wind sector was not a significant factor in the shortfall; it was gas and coal.

Deregulation has been an abysmal failure.

Usually It takes 24hrs to turn an issue like that around. If those sensing lines are not hat traced, adding it would require a design mod that would not be quick. The smaller enclosures to the right of the main turbines are the 3 feed water pump turbines. The turbines are inside the enclosures but the pumps are outside. They are insulated but I’m not sure about heat trace on those lines. Adding heaters at the pumps would be a quicker fix.

There are no walls on their turbine buildings. While they may house their AFPs in the Aux building, it is most likely that their Main Feed Pumps are in the Turbine Building, especially when the news release from the site states that the lines were effected by the cold weather. Also, lets face it, they don’t have walls because the plant is in Texas and it was cheaper to build that way. The nuclear industry has grown and learned a lot since the “construction” days.

Rod, I was baffled by your nuclear safety comments at the end of the article. Did you miss the part in the press release where this was identified as an automatic trip? Operator decision making was not a factor in this unit going offline.

Good article. Could add to the paragraph on the EEA Stage 3 load control the ERCOT graph that shows that the actual load they are supporting is 15,000 MW to 20,000 MW below the day ahead forecasted peak (2/16 2/15 even greater delta). This shows how far off they are from meeting the expected demand. The trip of the unit, 1,350 MW is a challenge, but they are not even close to their projected demand.

Hi Rod!

Thanks for the great article. I was curious, do you think this would open the door to discussing the possibility of new nuclear like STP 3&4, Comanche Peak 3&4, or entirely new SMR units?

No investor owned utility will build a large nuclear station without federal subsidies, loans, guarantees etc. We don’t even have the skilled personnel to build more than perhaps one unit at a time.It would take a few years to even fabricate the larger components such as the reactor vessel which would have to be outsourced, probably to Korea.

But the US produces excellent music videos. So we CAN do so e things right if we set our minds to it.

Your comment definitely saddens me. It is true in every respect. This country WAS able to build nuclear plants. I think the SLEP (service life extension) programs have demonstrated the quality of the design AND the construction practices. We may even have one or two make it to 80 years?

I went through a Steam Generator replacement refueling outage. Our steam generators were made in Spain! I think we were one of the first plants to go through this after the Westinghouse fabrication facility in Florida closed down. So sad.

My boss’ son worked for the Shaw Group, that had a major chuck of the Vogtle and VC Summer “new construction” projects that started during the Obama administration. I asked him endless questions–fascinated that we were once again building plants. What a mess. Scandia is mired in some scandal about it, and they pulled the plug on VC Summer 3 and 4 after spending 9 billion. Uggghhh. A major factor was Westinghouse Nuclear (then owned by Toshiba??) went under.

Bravo to Georgia Power with clamping down and committing to completion. But you are absolutely right, the Vogtle 3 and 4 is probably consuming every last bit of nuclear construction expertise we still have in this country. So sad!

Thanks for spotting that. Yes, PV is a non-event during the night.

During peak demand periods, Energy Northwest NPP is directed by Bonniville Power, “no touch” as a trip could destabilize the grid. During this catistrophic demand event, a sensor(s) caused 1200 MWe to go off line and 4 million people in Texas are in the dark and extremely cold. 1200 MWe is enough juice for 1 million homes. If the trip is due to an instrumentation error, oh my.

For STP Unit 1 — it depends where the Unit is in life for that load of fuel. Fuel cycles are typically 18 to 24 months. Also, not known if the reactor tripped or only if the Turbine tripped. If the Unit is late in core life, and the Reactor tripped (in addition to the Turbine), that could easily take three days just to restart the Reactor prior to synching the generator back to the grid. If only the Turbine tripped, and the Reactor remains critical but at 0% power, return to service can be much more timely. Not really familiar with that plant’s design.

Really too bad that occurred. From the article, it appears they have been operating very reliably.

Well I do know that STP was at 100% before the trip. Turbine only trips are set at much lower power level- say 15%. The primary can’t handle the level of instantaneous heat rejection that happens at 100. So the reactor must trip.

They will get back on line as fast as safely possible. I worked at a plant that tripped during a previous cold event. It was a bad deal for everyone. But these things happen. Now it’s incumbent on them to do all the right things to get back online and prevent a similar occurrence.

But really what must occur is Texas getting past the pipe dream of wind and solar. They are nice to look at and score points with the eco-warriors but never there when you need them.

The refueling outage is this year in the fall.

What I don’t understand is how the ERCOT reserve was pushed to the limit by a winter freeze. Grid systems are designed to have enough capacity for peak demand with a nominal percent of the generation offline for maintenance and possibly some unexpected generation outage at peak, but not much. It costs real money to overbuild.

Having said that, surely peak demand is in the record-breaking summer heat. The demand on lighting doesn’t change much because of air temperature. Many, if not most, homes heat with gas. No one air conditions with gas. Therefore, with lighting demand nearly constant, one would think that summer cooling is much more demanding on supply than winter heating. I know my highest summer electric bills are much higher than my highest winter electric bills.

What gives here with the claims that the cold weather overburdened the supply capability?

Much to my surprise I looked up another southern state and history for last 2 years shows winter peak exceeded summer peak. I can’t explain that but your question seemed to spark a memory that’s how it was. The difference was insignificant but still a surprise.

In the case of Texas I think the final chapter will say they were fine UNTIL generation started falling off line. I don’t think demand got them as much as declining generation did. There might even be a chapter explaining how the transmission operator did a marvelous job preventing complete blackout once the tragedy started.

Most Houston area homes heat with electric and likely many Texas homes in general (~60% I believe). Same for cooking. Gas heat is not all that common in the area.

The summer cooling demands are higher and therefore the planned maintenance on the thermal plants is during the winter. Also, the heat waves possibly to not overwhelm the entire state in the summer, like the cold snap did here. As you know, they’re on their own grid so when the whole state experiences this event, they’re screwed. Add on top of that the lack of winterization because of deregulation and selling electricity for cheaper than it costs to produce (therefore no returns for infrastructure investment) and here you go. Texas energy intellects have been warning of this for many years, it was totally predictable.

In 1958 in Dallas, my grandfather built a house with a “year-round” gas-fired heat pump, operated on the absorption system. And it’s not rare for big buildings to be air-conditioned with gas, typically with absorption chillers. In fact the University of Texas campus in Austin has a central total-energy plant which incorporates gas turbines as well as steam boilers & heavy refrigeration equipment.

But electric heat is quite common in Texas. Straight resistance heat isn’t terribly rare, because the number of heating days a year is small. Electrically-driven heat pumps, sharing equipment with the AC plant which runs for twice or three times as many days a year, are an especially attractive option, but when the outside temperature falls too low, they require “booster” resistance heat. When that kicks in, demand spikes.

Likely simple matter of not enough heat tracing on the sensor line. Have seen this problem at a number of new combined-cycle plants that did not fully consider how much mischief really cold air and wind can cause. We typically used blow torches and potable space heaters to “band-aid” problem and we’re back on line after a shift or so. Seriously doubt that could happen at a nuclear plant, considering the mind numbing paperwork involved.

I waz the lead I&C inspector during the completion of both units at STP from 1974 until 1988. It’s been many years and I can’t remember these specific pressure transmitters but if like most they are mounted below the process with the lines maintaining a downward slope. Since these are static lines a simple fix is to fill the lines with the same water/antifreeze mix used in your car. It’s a practice used in many industries outside of the nuke industry.

I retired from Luminant after 32 yrs I&C tech. before that 5 yrs at Dow Chemical Texas Division. At Dow we did use antifreeze in the low and hi side of sensing lines . I guess it would play hell on the water chemistry required?

Rod,

I endorse the earlier comment by Mike Keller, who wrote, “Could be as simple an item is a lack of or not enough heat trace/freeze protection on the sensor line?”

In Canada, we pay particular attention to this very important cause of system failure in cold weather.

Jerry Cuttler

By the way: Isn’t there a water reservoir in case of coolant loss? I think I remember seeing a photo from STP that showed such a pool. It should be completely frozen now, shouldn’t it? Greetings from Germany, it just becomes a bit warmer now.

Hello, Detlef. I do not know PWR-4 design specifics, but fro mthe common sense:

1. There is no continuous run on coollant loss. No way. All the facilities for that case are memery limiting disaster magnitude. Ideal case – they ensure reactor was SCRAMmed and then is being safely cooled for a day or two, until fission reaction “hot” isotopes mostly die out and “residual heat” generation falls down.

But that is ideal case. Chernobyl-style reactor (1GWe grade) pumps 8800 tonnes of water through every hour! Just to give you point of reference.

2. Actuall coolant loss remedies are highly pressurized water tanks, having many tonnes of super-refined water. You can not pour just any water into reactor. Or, to borrow from Russian gallow humar, if it was not one specially prepared ultra-clear ultra-uniform water chilled down usually, then you can only inject it into reactor once. And scrap the reactor later. And why that water is super pressurized – because the pressure in that tank should be equal to the pressure in the reactor itself. If disaster is so bad that primary loop looses coolant – you can not trust in reliabiltiy of computers, pumps or anything. Only raw physics. As soon as reactor pressure falls down below tank pressure, the tank “spits out” its water into reactor. Primitive and reliable like falling rock.

But all in all it means those emergency tanks are only having water for 3-4 minutes. Enough to SCRAM the reactor, but nothing above it, not even residual heat removal.

STP designs probably do have such a tank, but it probably was not used, as there was no real leakage and pressure did not fall. Anyway, it would not prevent SCRAM, tanks like that are designed to help SCRAM not prevent it.

…to be continued

The pressure drop was on the secondary side… the tanks you’re referring to for safety injection are for the primary side only.

Erica . . . . I do think some designs have “Condensate Storage Tanks” that can supply purified water to the secondary if necessary? They wouldn’t be “injection” like the SITs you are referring to (which are pressurized and aligned via check valves to automatically inject as soon as primary pressure drops below SIT pressure.)

3. Fukushima-1-1 had an early low power design, and non-pressurized BWR design at that. They had the “residual heat removing” tank. Indeed. But this tank was inside the reactor building, and it was set above the reactor. You do not need design like that when you have electricity and pumps are running. It is when your pumps are dead you would need such a tank. But that means it has to be ABOVE the reactor, to make gravity do the water flow.

However:

3a) even with Fukushima-1-1 that tank was only lasting… oh i forgot… but it was like 2 or maybe 8 hours. When they failed to restart pumps during those few hours – the tank run dry. And no, not on working reactor, but on timely halted one! still only few hours.

3b) it is only possible in non-presusrized designs, where you kind of can throw watter from roof from buckets.

3c) with Fukushima-1-2 and further reactors, which had more power than #1 – there was no such tank. It was not fisible to do for higher rate reactors EVEN on BWR design.

So, basically, no. Would STP had such a tank, it should had been inside buildings and you would not see it. And it STILL would not allow operation, only safe halting.

4) you would really see many NPPs having ponds. Or built on river sides. Or (Japan) on ocean sides. Well, those ponds are never let into primary loop. Because it is absolute requirement for primary loop to have ultra-finely prepared water.

Those ponds are actually thermal exchangers for the 2nd or 3rd loops. Normally. Fukushima-like BWR designs only have one single loops, but that is too extravagant, today i believe eveyr reactor has at least two loops. With loop (N+1) used to cool down loop(N) without letting radioactive contaminated water out of it.

In other words, the ponds, rivers, oceans you see in aerial photos of NPPs are actually tertiari or quaternary or sometimes secondary coolant loops, but they never are part of primary loop, thus they can do nothing for the leak of primary. The insulation, separation of loops is primary feature to contain radioactivity within.

Thank you for your helpful responses. I did not want to claim a problem in the primary circuit, at least not currently. My reference to Fukushima led to this misunderstanding.

What I meant was indeed the ponds you mentioned in 4). They are not frozen at the moment either. I saw photos of weather stations. They show the Colorado River with fog.

Even if those ponds would be covered with ice on top – they would hardly froze deeper. There below there would always be heat exchange with reactor-heated water pipes. I think those are not “previousl loop” pipes running right through the pond/river/ocean, but rather there is pumping of water from pond into heat exchanger and then back to pond. However, as long as NPP is running – there is constant stream of heated water back into pond. I heard, in Soviet/Russian NPPs fishery was wild on those ponds, as the always warm water was making everything flourish.

Now that STP got halted those ponds might start freezing through indeed. But given water’s large thermo-inertia i guess they would not have enough time left until next week should bring warm weather back to Texas. They would probably grow covered with ice, but not more. Just a guess.

Only one unit tripped, not both. Even if the other unit went offline, it likely wouldn’t freeze before it heats up in Texas this weekend.

@Erica this only makes it weirder for me.

Since another unit is going on – they have unlimited supply of hot water – they can unfreeze any pipe on their location, just pour hot water over, or yet better make makeshift piping around it.

But whatever. Texans have harsh winter crysis reoccuring about every 10 years. Maybe they are right. Why invest into infrastructure safety margins that only is used for a week or two per dozen years and is waster all the rest time?..

@Arioch

I recommend avoiding your recommended “hot water” method of deicing, especially if it involved a car windshield.

Even the secondary side of nuclear power plants requires a bit more care than installing “makeshift piping around it.”

On the other hand, there are winterization processes that might have been able to avoid this event at a reasonable cost, if the operators had been able to foresee exactly which parts of their systems were vulnerable to freezing under the temperature and wind conditions that their plant experienced.

I’ll bet this particular sensing line will not cause another outage and that there have been efforts during the continued cold to identify any other potential weak spots.

@Rod glass has slow thermo transmission, so windshield would get shattered. And it does not even take cars. Go to a kitchen and take usual glass jar like 3 or 5 litres. Boil the water and pour it into (don’t!) – it shatters.

OTOH, would you instead drip boiling water one drop a time – high chances the jar would accomodate it.

However metallic pipes have better conductivity, and also they are huge, so even a garden hose size hot water stream would be like cold for them. The real problem for me is how one gonna remove the water after it slided off the pipe onto the snowed ground, that would be real pain in the plan….

And there is always arbitration, there maybe are people freezing to death, and there are costs for NPP to repair any added damage that makeshift emergent fixes always cause. It is up to Texans to decide which is more important.

And since it turned out Texas is replaying harsh winter stike crysis about every dozen year – then… well, afterall it is up to them how to run their state. Indeed, emergent risky makeshift “save the day” would be stupid to suggest if they consider there is no emergency.

So, pardon my bitterness, but w.r.t. “On the other hand, there are winterization processes” – i come to think there actually are none (meaning -20C of today for that “winter” not +5C), year on year…. And so all our suggestions, both rushed and perfectly polished, are actually moot.

Hi Detlef, I worked at STP in 1988 as an engineering co-op from the University of Texas at Austin. You are correct in that there is a UHS (ultimate heat sink) concrete-lined reservoir that is separate from the massive 7000-ish (from what I recall) acre cooling reservoir. However, from what I understand, the issue was that a feedwater pressure sensor line froze, not the primary cooling reservoir (or the UHS). But from what I recall, both of these reservoirs are secondary cooling, not in case of loss of primary coolant. BTW, how is the status of nuclear power generation in Germany these days? Still trying to shut them all down? Or have cooler/smarter heads prevailed?

7000 acres is 11 square MILES. Are you SURE you remember that correctly? Because I’m sure you don’t.

@E-P

From the link that Ed Leaver posted – “The Main Cooling Reservoir (MCR) associated with the STPEGS is a 7,000-acre off-channel reservoir which is capable of containing 202,600 acre-feet of cooling water at its maximum operating level. Construction was completed in 1979 and initial filling started July 1, 1983.”

Texas Water Development Board: The South Texas Project Nuclear Generating Station.

These are likely to be steam driven turbine pumps with identical designs. As Don Dube says, a common mode condition like sensing lines freezing is most likely to result in common mode failures: I.e, both pumps trip however not likely at the exact same time. Thus, the first pump to trip likely trips the plant before the second one has the chance to do that. Small affects like differences in local breeze strength or other potentially weather sheltering affects are likely to be at play as well.

As our old friend, Jack Gardner, used to facetiously say in our “mild environment” equipment qualification justification discussions, while there may be two deacons chairs built as near identical as reasonable and exposed to the same mild environment (that is, it doesn’t change because of the event for which they are credited), they are unlikely to fail at exactly the same time. Thus, common mode failures of the chairs is not a concern.

In the final analysis, as main feed water pumps are part of the secondary side non-safety related plant, common mode failures would not have had to have been analyzed and designed around. How’re, common sense would have one do that and incorporate freeze protection if the likelihood of freezing weather at the site and equipment is at all probable. Nuclear plant trips for whatever reason are a challenge to the plant and its operators and must be minimized for safety and reliability reasons.

Good to see that Don Dube’s still contributing to the industry’s knowledge base.

Open turbine decks are fairly common on both fossil and PWRs in the South, I imagine its cost saving. The feed pumps are not on the turbine deck, they are inside the turbine building, likely on the ground floor, where it can obviously get cold enough to freeze uninsulated instrument lines. Pretty good guess they never planned for sub-zero cold in their design. I would wager there is no installed heat in the turbine building at all at STP or heat trace for that matter. The safety and reliability planning that goes into the secondary side of a PWR is not on par with the primary side in my limited experience.

Roy, thanks a lot, but how hot is the water out of those pumps and how long are the pipes?

I mean, in pressurized Chernobyl-type reactors the water out of pumps is +190C.

It would be not easy task to ice clog pipes which are pumping four thousands of tonnes of +190C water each hour. Even if you put those pipes into the ice of Nothern Pole.

I would think STP has Fikushima-type non-pressurized BWR, but then Wikipedia says PWR, and PWRs should have very hot water in primary cooling loop.

So, i am still puzzled a lot. It takes not just ignorance, it takes some true creativity to design NPR where primary loop can be frozen during full load work under any weather condition. Even to do it intentionally would be non-trivial task.

I frankly feel like watching some Mexican TV series, with every next twist in the plot getting more and more extravagant.

It doesn’t sound like the issue was with a frozen water line or lines, it sounds like “sensing lines,” an I&C issue (instrumentation and controls). I don’t know about STP, but the original design for the secondary side of nuclear plants were actually not dissimilar from large coal-fired plants in a PWR. The steam generation side to the turbine, and the condensing side return to the feedwater system were more alike than different–with the basic difference being the steam generator instead of a boiler.

Those feedwater control systems were often analog, and used a ‘tapped’ portion of the process being sensed through a thin line as a direct input for a pressure balance type control to then modulate the feedwater pump. A steam driven feedwater pump would typically have a speed control analog loop that modulates the steam flow and pressure to the pump’s turbine wheel.

This kind of line would absolutely be vulnerable to extreme temperatures. If these sensing lines were on the steam side of a steam driven feedwater pump, the “quality” of the steam in a PWR is very close to saturation (little or no “superheat,” which makes moisture in the steam an issue throughout the secondary side.

When we had something like this occur–the “root cause analysis” typically would go into detail in terms of corrective action for a condition like this. And those analyses were quickly distributed throughout the industry for review. The NRC may mandate some kind ‘hardening’ for this type of system.

I suspect any “fix” for this would be relatively inexpensive by NPP standards?

> This kind of line would absolutely be vulnerable to extreme temperatures

Depends obviously hwo you do it, engineering-wise.

You may pull 1cm thin pipe for 100 meters, then gather there all the sensors and there – a single electric wires connections panel, or even just a digital controller (but we talk of NPP built in 1980-s and designed probably in 1970-s).

Ot you may make that appendage as short as possible and keep it aligned parrallel to main pump. Then you would have complications for electric cabling, but water would never froze there.

It is indeed the matter of choice, what goals and specs were given to designers…

> were often analog, and used a ‘tapped’ portion of the process being sensed through a thin line as a direct input for a pressure balance type control

which means there is continuous steam of hot water inside, albeit a thin stream maybe. Just add thermoinsulation, construction foam one can by in every shop, and remove it by hands month later.

Guys just do not think ahead. They do their instructions. If they were not given ones – then they do not invent them. And there was no one hired to write special operating manuals for winter.

They did not even open taps to make water flow non stop in their houses. No one taught them in schools about ice expansion and what it might mean for their households… I heard reports even some town-wide water pipes were iceclogged somewhere…

It is emotionally devastating getting news like that from a country usually considered very educated and very technologically advanced.

From far away I don’t understand what’s going on with Texas power. I read about temperatures of 20 F degrees at night and 28 F degrees during the day (on Monday). In Germany, we had five days of minus 20 C degrees at night and minus 10 C degrees during the day, that is about minus 4 F degress or 14 F degrees. No wind turbine outages were reported. The average performance was probably worse than usual, but no disasters.

I understand that Texas is a sunshine state. But 97% outage of wind power? Not even snow can do that, maybe a long time freezing rain?

@Detlef: In most of mid-continent US, it may get very cold but wind turbines have antifreeze and heaters to cope with it. Just like Rest of World. What they can’t cope with, or at least generate from, in mid-continent US, is the very still cold air that frequently follows the passing of a cold front.

It is also possible for wind speeds to be too high during the initial storm, and turbines must feather and shut down during that time.

I don’t know what the wind patterns were the past five days in Texas, but ERCOT does. So does NWS. And so, eventually, shall we.

In general, wind patterns have positive correlation out to about 1000 km, roughly the reach of the British Isles, beyond which they become stochastic. ~1000 km is also ERCOT’s north-south extent, so their wind reliability could be improved by inter-ties with Southwest Power Pool and Western Electricity Coordinating Council. They already have 800 MW ties with SPP.

Map at https://www.aect.net/hot-topics/non-ercot-ratemaking/

TX’s real problem is that it is an island grid. Large scale reliance on an intermittent power source (and TX is more reliant on wind than any other state) is a prescription for disaster for an island grid; which is why HI cannot achieve it’s renewable goals and continues to rely heavily on oil & coal. IA and CA are also heavily reliant on wind and solar but are able to import conventional dispatchable electricity from out of state on short notice, TX cannot.

ERCOT knew ahead of time demand would exceed its ~70GWe capacity for the cold front (greater demand for electric heating homes than AC in notorious TX summer) but couldn’t import additional power. El Paso (outside TX island grid) can import power from out of state and isn’t being hit with sustained blackouts.

So yes, ERCOT is ultimately to blame for not insisting on either interconnections to the larger national grid (ultimate backup) or additional reliable baseload with enough on-site fuel supply to ride out foreseeable supply interruptions. Natural gas just doesn’t qualify. So the three card monte routine between wind & gas collapsed.

Only nuclear fission can store sufficient fuel on-site (typically now 18-month fuel cycles) enabling refueling outages in low demand spring/fall seasons. Even with the outage of STP-1, ~75% of fission capacity remained available vs only 3% wind.

TX should plan at least ~25GWe of fission baseload (and back out its gas to reserve/peak/shoulder duty and domestic heating) if it wants to remain an island.

ERCOT may be an island, but it’s an island nearly as large as Great Britain, & it does have interties to the outside world.

The true problem here is that the “firm” capacity is composed to a great extent of stations dependent on interruptible gas ― and that is equally true across much of the rest of the USA, so tying in to other regions where that’s true wouldn’t help much. It was either in Nebraska or Iowa that a nuclear station was closed, with the official statement of the owners being that it couldn’t compete on power cost with the combination of wind & “cheap natural gas”. I was outraged by this, because the “cheap” gas is NOT firm-delivery gas. In an extreme weather event, you have to assume that the weather-dependent generation will be off-line, but you ALSO have to assume that the firm-delivery gas customers will be drawing close to maximum, so the pipeline pressure will be low, & there will be very little left for other customers, including electric generating stations.

I certainly wouldn’t mind having 25 GW of fission plants, but honestly, we’d be in a much better position in Texas right now if Comanche Peak 3&4 (1700 MW each), & South Texas 3&4 (1600 MW each), had been constructed as planned a decade ago.

ERCOT’s inter-ties are fairly small. In 2011 ERCOT imported power from Mexico via several ties. Mexico had their own problems at the same time this year. Reason-Gas imports from Texas were cut off.