Fission is an elegant way to heat a gas

What if it was possible to combine the low capital cost, reliability, and responsive operations of simple cycle combustion gas turbines with the low fuel cost and zero-emission capability of an actinide (uranium, thorium, or plutonium) fuel source? Machines like that could disrupt a few business models while giving the world’s economy a powerful new development tool. That would be especially true if the fuel source was in a form that could withstand all possible temperature and pressure conditions without being damaged.

I’ve been inspired by and chasing that goal with varying levels of intensity since 1991. The pursuit has been rather disruptive to my personal life but with the help of a supportive family and a lot of exceptional friends, the disruptions have combined in a mostly positive way. (I’ll admit — and my wife and children will testify — that it has not always been easy be me or to live with me.)

I cannot claim originality in the idea of a nuclear fission-heated gas turbine. It is a concept that has been discussed and evaluated since the days immediately following World War II.

Both of the necessary parts of the system, however, were quite primitive at that time. Brayton Cycle gas turbines were just starting to enter into useful service and were not yet commercially available. It had only been four years since the very first atomic pile had proven that it was possible to control and sustain a heat-producing reaction using an actinide fuel source in a carefully configured array of selected materials.

One of the primary conceptual leaps required to understand how such a system can work is to recognize that a Brayton Cycle does not have to discharge directly to the atmosphere; all the basic cycle needs is a way to return the gas temperature and pressure to the starting point of the cycle – normally atmospheric air at available temperature and pressure.

In combustion gas turbines like jet engines and simple cycle gas turbines, the standard practice is to discharge the heated combustion products and use a continuous supply of fresh air, but in a system that does not use the air as part of the heat producing chemical reaction, it is better to simply direct the discharge of the turbine through a cooler and then return the cooled, depressurized gas back to the compressor inlet.

A closed Brayton Cycle allows designers to choose among a larger number of working fluid options, keeps any stray fission products or gas activation products inside a controlled system, and allows the possibility of using higher system pressures to shrink component and piping sizes.

Most of the gas cooled reactor designs that have ever been proposed, dating all the way back to the Daniels Pile, have been based on using helium as the working fluid. (See page 63 of the document linked with “Daniels Pile.”) The primary exception has been the CO2 cooled Magnox and Advanced Gas Reactor (AGR) in the UK and the several French gas-graphite reactors built before the decision to focus on developing a series of reactors based on a Westinghouse-designed pressurized water reactor.

Neither of those gases, however, enables the use of conventional gas turbine machinery. They both require specialized compressors and turbines, so there is little synergy between the sixty years of design refinements, manufacturing infrastructure, proven operational performance, or trained operators and maintenance personnel that enable combustion gas turbines to be such an obvious choice for power plant purchasers.

Most of the proposed nuclear-heated, closed-cycle gas turbine projects have also envisioned systems that operate at high pressures and strive for maximum thermal efficiency using several stages of preheat and recuperation. Those design choices add to the complexity of the system and move away from the initial goal of combining the low capital cost, reliability, and responsive operations of a simple cycle gas turbine with the low cost and emission free nature of an actinide fuel source.

Combustion gas turbines use atmospheric air, a readily available gas composed mainly of 80% nitrogen, 19% oxygen, 1% argon, and a complex mixture of various trace contaminants. That choice leads to some engineering complications, but it works and provides a key component of combustion, the heat-producing chemical reaction using hydrocarbon fuel sources. Since a nuclear heated system will use a closed-cycle, it is worthwhile to more carefully control the working fluid to remove the argon, which would be activated as it flows through a fission reactor, and to remove the trace contaminants.

It might also be worthwhile to more carefully control the ratio between N2 and O2 for optimal compatibility with the system materials. Because combustion turbine machinery is designed for operation over a relatively narrow range of input pressures, it is best for the early models of closed cycle gas turbines to keep the temperatures and pressures in a similar range.

Since nuclear fuel costs on a per unit of heat basis are substantially lower than the cost of the clean hydrocarbon fuels suitable for use in a combustion turbine, thermal efficiency is not as important as engineers normally assume, so may be beneficial — especially for early generation machines — to avoid any system complications in order to keep capital costs low.

Though not in widespread use, gas cooled reactor technology has made some significant advances since the Daniels Pile conceptual design. There is a prototype operating in China called the HTR-10, and a demonstration project called the HTR-PM under construction that will use two pebble bed helium-cooled reactors to produce steam that will be combined into a common header to supply a single steam turbine.

The fuel form and materials chosen for that reactor are compatible with an N2/O2 gas mixture. As the existence of the HTR-10 demonstrates, the pebble-bed fuel form enables a variety of reactor power levels to use exactly the same fuel element. Size changes do not require altering the length of fuel assemblies, they simply require changing the internal volume of the reactor to allow more or fewer pebbles.

There is nothing magic about the 6 cm diameter pebble that seems to have always been the chosen fuel element of pebble bed reactor designs – smaller fuel elements would provide some advantages. Nuclear rocket engine designers have proposed fuel elements as small as a grain of sand, but there are disadvantages of making the elements too small. A fuel element the size of a shooter marble might be optimal, but early generation units would probably stick with the 6 cm pebble.

Pebble-beds also allow designers to capture some of the advantages of mobile, liquid fuel without having to deal with the disadvantages of fission products that are not tightly contained in a solid fuel matrix. Most of the pebble bed designs that have been produced have a system that enables continuous refueling. Some have included features allowing portions of the core to be “dumped” to a holding tank under the reactor that is designed to ensure safe retention of hot fuel and a guaranteed sub-critical configuration. In their simplest form, however, pebble-beds can be stationary and not include the complexities of a continuous refueling system.

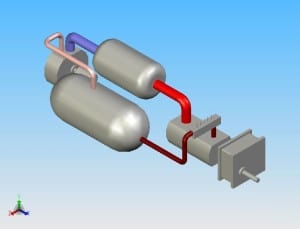

The basic Adams EngineTM includes a variable speed air (N2/O2) compressor, a stationary pebble-bed reactor, a throttle-controlled turbo-expander, and a gas cooler that uses either an available water source or air as the cooling medium. The highest internal pressure in the system will be roughly 1 MPa – ten times atmospheric pressure. That pressure offers interesting options for the reactor pressure vessel construction and piping manufacturing.

As long as the reactor thermal power is less than about 300 MW, the reactor can be designed so there is no need for any decay heat removal systems. The fuel can withstand any possible temperature without being damaged.

There is no fundamental reason why a designer cannot add a heat recovery steam generator to make an Adams Engine into a combined cycle, but it is not obvious that the improved power output and thermal efficiency would be worth the additional capital cost and system complexity.

One of the greatest compliments an engineer can receive is acknowledgement from his peers that he has created an elegant solution to a difficult problem. Antoine de Saint-Exupéry made the classic statement of engineering elegance:

A designer knows he has achieved perfection not when there is nothing left to add, but when there is nothing left to take away.

I hope at least some of you will agree that an Adams Engine could be an elegant solution to the challenge of combining low capital costs, reliability, responsiveness, low fuel cost, and zero emissions without having to make too many sacrifices.

There was once a patent on the power control system, but that expired about ten years ago when I decided not to pay the maintenance fee.

The above is a simplified description. There is more detail available if you follow the links for the various mentions of Adams Engines. Questions are always welcome.

One more thing – if you think this kind of information is valuable, feel free to make a donation that will assist in keeping the lights on, the computer running, the site operating, the food on the table and this design in the category of open source information that is freely available for exploitation.

If you think, but I’ve already donated, ask yourself how many times you have tipped your favorite bartender, waitress, garbage man or valet. Is the service provided here any less valuable?

I have always liked the Adams Engine concept. Taking simplicity to the extreme, the working fluid would be normal air and there would be a system for maintaining the proportion of activitated materials in the working fluid below a reasonable level, perhaps a HEPA filter or something. In this way, the system would be independent of a continuous supply of refined working fluid, allowing greater simplicity of operation and maintenance. Of course, enabling such a choice would probably increase the exposure of the public to radioactivity somewhat, but I like to think that the level of exposure could be controlled to a safe level. Or is that nonsense thinking?

I guess what i’m looking for is a mini-nuclear generator that has the same ease of use as a diesel generator. It would seem that using normal air as a working fluid and taking the necessary steps to allow doing that without causing too much radioactive exposure would do much to achieve such a similarity.

The argon content would make this rather undesirable, especially given that the activation product 41Ar (a 1.3MeV gamma emitter) is an inert gas and cannot be filtered. The presence of even a small quantity of argon in a reactor greatly increases the shielding required on any coolant pipes outside the vessel.

@ Joris,

“I guess what i’m looking for is a mini-nuclear generator that has the same ease of use as a diesel generator.”

Yes, I am also looking for something like this. Of all the designs I have heard about this one is the simplest and has the potential to be the least expensive – in my non-professional opinion.

@ Rod

I do have a question about the “pebbles” .. How dangerous / hazardous would a single pebble be to hold or be near? Would this be a matter that a single “pebble” would be safe by itself and only begin to generate heat when close to other “pebbles?”

Do you have any progress reports on the fuel fabrication they are doing here in the USA?

@David

Before being used in a critical reactor, single pebbles will be able to be handled directly, just like unused fuel elements for light water reactors are. They contain only alpha emitting isotopes and have a 0.5 mm fuel-free shell around the matrix of TRISO particles.

Once the pebbles have been used, they must be maintained in shielded, protected containers.

The fuel testing program in the US continues its steady progress and is meeting its planned milestones. It will be available to support reactor construction in the early 2020s.

http://blog.ngnpalliance.org/triso-fuel-news/

Unfortunately, given our current fuel testing infrastructure in the US, this is simply a slow process that cannot be accelerated due to limitations on the availability of suitable neutron fluxes from test reactors.

Does the gas mix need some oxygen to improve the behavior of the coating on the pebbles? Would radiolysis of the N2 and O2 molecules lead to some undesirable NOX compounds?

Nitrogen 14 has a neutron absorption cross section 500 times larger than carbon’s, and ten thousand times larger than oxygen’s. Is it just the density that rules out CO2 for standard turbines?

n

@John ONeill

In some cases, the O2 will help ensure long life behavior for the turbine blades.

“Just the density” is a statement that obscures a lot of complexity. It was “just my height” that ensured I would never be a basketball star.

The optimal ratio of N2-to O2 might very well be close to 100% N2. It might also be worthwhile to use pure N-15, a gas that makes up 0.36% of natural N. There are ways to separate N-15 from N-14. Some of those ways are chemical and have been in use for more than 60 years.

Rod,

Has the prospect of using CO instead of N2 been looked at? Yes, CO is poisonous and it can react with many metals at high temperatures, but this is a CLOSED Brayton cycle (so the poison will stay away from people) and there are a materials that are resistant to carbon monoxide corrosion. The density and thermodynamic properties of CO are very close to air as I recall. As far as the nuclear characteristics go, CO is clearly better than N2 and it breaks down at an even higher temperature than N2.

As I see it, the big limitation would be incorporating CO corrosion-resistant materials into the gas turbine. Maybe the materials are available, but maybe they are not.

N-15 separation would be very nice. Maybe following the Deuterium enrichment model would be the way to go. The Canadian method has been to use hydrogen sulfide exchange to enrich to one grade and then further enrich with distillation. N-15 isotope separation might use nitric acid for the first stage and then cryogenic distillation as a finishing step.

Rod,

Further to the use of CO in an Adams Engine, it seems that SiC is resistant to attack by CO up to 1200 C (a web search with the terms “Pitvak Fedoruk carbon monoxide” will lead you to an article regarding SiC and high temperature CO)

Molybdenum has carbide formation in CO above 1400 C

Technetium? That would be very interesting. While I can’t find anything on the web about that, it would not surprise me if that metal also has great resistance to corrosion by high temperature CO.

Aren’t these sufficient materials to make an Adams Engine with CO — and thereby sidestep the problems with N2? SiC coating alone could do virtually all of the corrosion protection.

Still, maybe the “yes, CO is poisonous, but . . .” bit sounds sort of like “Apart from that, Mrs. Lincoln, how did you enjoy the play?”

@Rick Armknecht

Though I appreciate the suggestion and the research you’ve done, trading the problems associated with N2 for those of CO seem a bit like choosing to jump off a cliff to avoid a bee sting.

Once we prove that C-14 is a minor challenge that is able to be effectively mitigated, N2 is essentially perfect for meeting our design objectives.

IIRC it’s not the density that’s the issue for turbomachinery design, but the ratio of specific heats, which is approximately 5/3 for a monoatomic gas (like helium), 7/5 for a diatomic gas (like nitrogen) and 4/3 for a gas with 3+ atoms in its molecules (such as CO2).

@George Carty

Density may not play a role in the ideal equations, but it has an important part to play in the design of physical machines.

Can you please provide justification for the statement that “The fuel form and materials chosen for that [helium-cooled] reactor are compatible with an N2/O2 gas mixture” ?

Pyrolytic graphite is virtually immune to oxidation until temperatures reach levels that are not seen in this system. Some have suggested that it is possible for that material to burn, but that is impossible when O2 levels are substantially less than 20% of the mixture.

Carbon and nitrogen compatibility is well known.

John ONeill mentioned “radiolysis of the N2 and O2 molecules lead[ing] to some undesirable NOX compounds.”

Would the oxidation potential of those NOx compounds be different from carbon monoxide (CO) which is known to react with graphite ? (Thnx)

@Jaro

Not perfect, but all issues mentioned so far have mitigations.

You are a brilliant man, Rod, and I have always said your expertise in all things nuclear is unequalled.

Rod Adams wrote:

Most of the proposed nuclear-heated, closed-cycle gas turbine projects have also envisioned systems that operate at high pressures and strive for maximum thermal efficiency using several stages of preheat and recuperation. Those design choices add to the complexity of the system and move away from the initial goal of combining the low capital cost, reliability, and responsive operations of a simple cycle gas turbine with the low cost and emission free nature of an actinide fuel source.

There is a certain engineering joy in maximizing the operating efficiency of a system. But the problem to be solved is to provide is to provide mechanical energy (turbine output) inexpensively. If this means more complexity (e.g., a combined cycle natural gas fired generating plant vs. a simple turbine), then so be it. But when fuel is very cheap (like nuclear), then it is better to minimize the cost of delivered mechanical energy, even at the sacrifice of fuel efficiency.

Automobiles are a good example of the principles that need to be used here. The conversion of gasoline to mechanical power could be made more efficient in a number of ways. But in seemingly every instance, the extra complexity adds so much weight that the resulting lower system efficiency cancels out the increased energy conversion efficiency. And the few things that work out to add net system efficiency often cost so much that they never pay for themselves with reduced fuel cost.

@ donb,

Very well summarized. This is the point exactly that Nuclear fuel is cheap to use because of the massive amount of heat per kg of material. We used to not care too much about insulating our homes because the fuel to heat them was fairly inexpensive. As that cost has grown the need to insulate has increased so that the cost of insulation is repaid by savings from energy consumption.

In the same way, if the energy is abundant and inexpensive using complex machines to maximize efficiency only makes sense if the cost of that optimization can be repaid in fuel costs. In this case – the billions spent in designing helium turbines will never be repaid in fuel costs.

@donb

There is a certain engineering joy in maximizing the operating efficiency of a system. But the problem to be solved is to provide is to provide mechanical energy (turbine output) inexpensively.

Your first statement contains numerous implications; I believe it comes from the misplaced emphasis on mathematics in engineering courses to the detriment of old fashioned “tinkering.” It might be one of the reasons that I was discouraged in my conversations with engineering professors during the brief period we were given to choose a major as plebes at the Naval Academy.

They did not talk much about experimentation and building things, but they did talk a lot about heavy use of calculus and lots of homework using equations. The math didn’t scare me, but it didn’t excite me either.

My joy in problem solving comes from using commonly available materials to solve challenges that stump other people. I’ve just been doing a lot of reading about how scientists and engineers worked in the 1900s-1930s, before “Big Science” and “Big Engineering” with huge flows of government money became the norm. It was an exciting and productive time, especially in atomic physics.

In my opinion, the Manhattan Project set nuclear science and engineering back about a half a century.

I’m not sure if your focus with this particular comment is new designs or established designs, but with established designs there is not a lot of system tinkering to be done. With mathematics however the total output of established US nuke plants has been uprated to the equivalent tune of at least a dozen new 1000 MWe plants. Mainly by pencil whipping conservatism out of initial licensing calcs. Works great for base load, however maneuvering has been lost because expected operational transients, like a RCP trip at 100%, can no longer be survived because RPS trip windows are so tight. The real mental tinkering to be done with that idea is to see if there has been a net loss in generation. If there is, it is not progress. Another biggie that comes to mind with me is forcing an auto Rx trip on a Turb trip (by regulation).

Your comment on the Manhattan Project begs an explanation. That conclusion is not obvious to me.

@mjd

Your comment on the Manhattan Project begs an explanation. That conclusion is not obvious to me.

I’ve been reading about the discoveries of Curie, Fermi, Szilard, Rutherford, Meitner, Joliot, and Chadwick. The pace at which they moved from almost no understanding of atomic structure to discovery of naturally occurring radioactive elements, neutrons, induced radioactivity, atomic fission, and chain reactions is rather astounding compared to the glacial pace with which fundamental knowledge has moved in the 65 years since the government became main controller of progress through regulation and controls on funding.

That may not quite be fair. When a field of investigation is brand-new, novel results come fast and easy. But there may be only so many discoveries to make; like an oil field, they can be depleted leaving nothing new to recover.

Finding what’s new below the scale of the nucleon (quarks and whatnot) is much more difficult, and one must make allowances.

@E-P

The sequence of discovery that I described proceeded from discoveries that helped people understand the basic structure of atomic nuclei up to the “chain reaction,” a process that opens the door for engineers and technologists who want to apply the discoveries in applications useful for mankind.

Scientists working in the privately funded labs that were the norm before WWII seemed to have been capable of making that journey from discovery to application far more quickly than those working in Big Science. They also seem to me to have been better experimentalists who did amazing individual and collaborative work with far fewer resources.

As you can tell from this line of comments, I am not a fan of the national lab system or the process by which physicists were distracted with big colliders and Tokamaks from doing work that was actually useful for the people who were forced to pay far too many people who enjoyed the steady work and the idea of being part of something big and mysterious.

Rod-

I remember all too well the engineering classes I took 40 years ago. Most of them were courses in applied mathematics. I remember one instance particularly well. The discussion of the day was Faraday’s Law concerning the open circuit voltage induced into a loop of wire. The mathematics were shown — a vector perpendicular to the loop whose length is proportional to the loop area, in dot product with a second vector representing the strength and direction of the magnetic field though the loop, then taking the time derivative of the whole mess.

Mathematically correct and elegant. But of little practical use, and hardly advancing understanding of what’s happening.

There is a much simpler (but still correct explanation). The open circuit voltage is simply the net amount of magnetic field through the loop, times its rate of change (time derivative). Now go ahead a apply whatever math is easiest for the problem at hand.

Math is a tool to be used to advance the understanding of an engineering problem, and to provide exact answers, after one understands what the basic problem is all about.

@Rod June 27, 2014 at 4:24 AM, @EP June 28, 2014 at 12:53 AM, @Rod June 28, 2014 at 4:46 AM

The original subject was innovation (I think) and the pace of progress. I agree with EP that the pace of progress by (all non-US) theoretical chemists and physicists early on was rapid, but natural. When the new door was opened there was just a lot of new stuff to be seen. The practical application story stagnation is messier. It is no doubt stagnant today because of regulation. But I am always amazed by discussions of very advanced reactor designs to find out most have roots in work done in the ’40s and ’50s, including several small working model innovations (Piqua, EBR, Elk River, Sodium Reactor, even Pebble Bed, etc), But the fact remains utilities locked in on two LWR designs by early ’60s, PWRs and BWRs, both of which were born of military applications, both before extreme regulations. The key argument today is there is no shortage of innovative ideas, but rather who should pay for development. I do agree development is beyond the resources of utilities, and also huge corporations without customers; but I don’t have an answer. I do think DOE can’t solve the problem of what to do with “something” inside a boot, with the directions written on the bottom.

@mjd

The high cost of development and market entry has its roots in the Big Engineering issue I’m talking about. The big boys like GE and Westinghouse had strong ties to government funding and worked hard to keep others down and out of their business model.

One of the items on my “do list” is more research on how GE pushed ALCO out of the reactor business. ALCO built a couple of very innovative small reactors.

“One of the items on my “do list” is more research on how GE pushed ALCO out of the reactor business. ALCO built a couple of very innovative small reactors”

Good luck with that one; add Alice Chalmers to the list too. Here’s a list of innovative reactors in the Army program: http://en.wikipedia.org/wiki/Army_Nuclear_Power_Program. Note especially they are all SMRs. Program died because AEC, still in promotion mode, determined no payback and cost of Viet Nam war. Live by the sword, die by the sword. But today SMR attitude is changed.

“The high cost of development and market entry has its roots in the Big Engineering issue I’m talking about.”

The high cost is due to the nature of the technology, just flat expensive on front end to do right, even Rickover knew that, and he was his own regulator.

“The big boys like GE and Westinghouse had strong ties to government funding…”

There’s the root of the problem plus add the whole Military Industrial Complex. GE, W, MIC, and Government are all one-and-the-same, then and now. They virtually all hatched out of the same egg; build a bomb, then cheaper bomb fuel. Rickover extended the tech to a different military app but still military. Eisenhower tried to change it with Atoms for Peace. The group of “They” couldn’t stop him, but they fought that idea with bomb proliferation fears.

I’m looking forward to your view. But I see it as “They” are one entity, with one vision.

@JohnGalt

The little guys might have gotten some scraps from the government, but the big boys dominated the crowd at the trough and have also worked hard to make sure they were involved in writing the rules that everyone had to follow. I believe they were following the ‘B’ school prescription of raising the barriers to entry to limit competition.

That is fine, but it is also fine for me to point it out and to work hard to ensure that as many people as possible recognize the true nature of competition as practiced by the dominant players.

I’m curious how you propose to deal with radioactive elements produced as a result of fission or fusion after you have changed their atomic weight in any nuclear reactor?

By definition, a nuclear reaction releases energy by creating basically unstable isotopes, which then break down over time releasing extremely carcinogenic radiation. If these particles are spread throughout our environment, it will turn life on this planet to a kind of “Russian roulette” in which you hope these particles aren’t lodged in your body.

Many of the isotopes are analogs of the elements which are building blocks of life – such as iron and calcium, so are concentrated in the biosphere.

You seem to be in denial of these basic facts. I’m curious how you deal with this reality – do you simply ignore it?

@Donald Grahame

Thank you for visiting Atomic Insights. This is a good place to find answers to questions like yours.

One thing that you need to understand about the radioactive by-products of fission is that they are extremely compact compared to the amount of heat energy that is released by the process. Since the volume of waste per unit of heat is so tiny, we can afford to design nuclear reactors that routinely contain all of the waste products in a controlled, carefully protected environment. That statement is true to more than “five 9’s” of accuracy.

Despite the characterization that has been pounded into the public, we have accumulated a small amount of this byproduct material during the nearly 60 years that we have been operating commercial nuclear power plants and naval nuclear propulsion plants. All of the US Navy’s used fuel is stored in a single facility in Idaho that occupies a small space on the Idaho National Laboratory site.

The rest is carefully stored and monitored in licensed spend fuel pools or dry cask storage systems on the same site where it was generated. Those storage facilities take up a small portion of the space at those facilities, essentially the size of a small warehouse or staff parking lot.

The next thing that you need to know is that radiation is not as carcinogenic as you have been taught. At high doses and dose rates, there are certainly dangers and proven negative effects; at lower dose rates and doses, the risk from exposure to radiation disappears into the background of normal risks that lead to the probability that about 40% of the human population will get cancer at some time in their life and about half of those who get it will eventually die from it.

There is mounting evidence that moderate doses of radiation are actually good for people because they stimulate adaptive response and repair machanisms.

There are dozens of articles on Atomic Insights that deal with waste issues and dozens more that deal with health effects.

If you look in the header of the home page, you should see a menu item that says “More.” Hover your cursor over that menu and then select “Archives.” For articles that talk about nuclear waste, select that heading under Topics. For articles that talk about health effects, select that heading.

Happy reading.

Once again, welcome.

There is another approach to using nuclear energy and a combustion turbine: use a closed-system helium cooled reactor to drive a turbo-compressor that drives the decoupled air compressor of a combustion turbine. This is a patented, brand new thermodynamic cycle.

From a technical standpoint, the working and cooling fluids of the combustion turbine are separated, which allows both processes to be optimized. The hybrid is significantly more powerful and efficient than the parents from which it is derived. The hybrid-nuclear cycle is the most efficient (~80%) use of fossil fuels ever created.

Nearly all the combustion turbines output is directed towards driving a generator. With today’s very large and efficient combustion turbines, a hybrid-nuclear plant is able to produce well over 900 megawatts using a single combustion turbine, a single steam turbine and a small reactor (at `620 MW thermal reactor output, the hybrid is an SMR). The ensuing economies-of-scale are stunning and directly lead to a highly competitive power plant.

The integrated hybrid-nuclear power plant has been in development for a several years and concept report will submitted to the Nuclear Regulatory commission late this summer in support of initial licensing activities.

For those interested, please send me an e-mail at m.keller@hybridpwr.com and we will forward a 1-page summary of this entirely US owned technology. We also have more detailed information that was submitted to the DOE earlier this year.

Your idea is clever, but it produces a unit with the disadvantages of both nuclear (regulatory and political problems) and fossil (fuel cost, GHG emissions) plants. 80% fuel-to-electric efficiency is on the order of CAES systems (not surprising, given the similarities) but fails to provide carbon-free base load. It would make more sense to use the nuclear power directly to run a generator, then use surplus electricity to pump up reservoirs for CAES. CAES can burn natural gas for peaking at about the same 80% efficiency, but it would only need gas when peaking power was being supplied.

Up to date, at least two-thirds of the energy generated in thermoelectric and nuclear fission power plants is wasted as heat, because they use conventional steam turbines with limited conversion efficiency. It is possible to produce an enormous quantity of electricity directly without steam turbines by making charged particles to work against electric/magnetic fields. http://www.youtube.com/watch?v=u8n7j5k-_G8