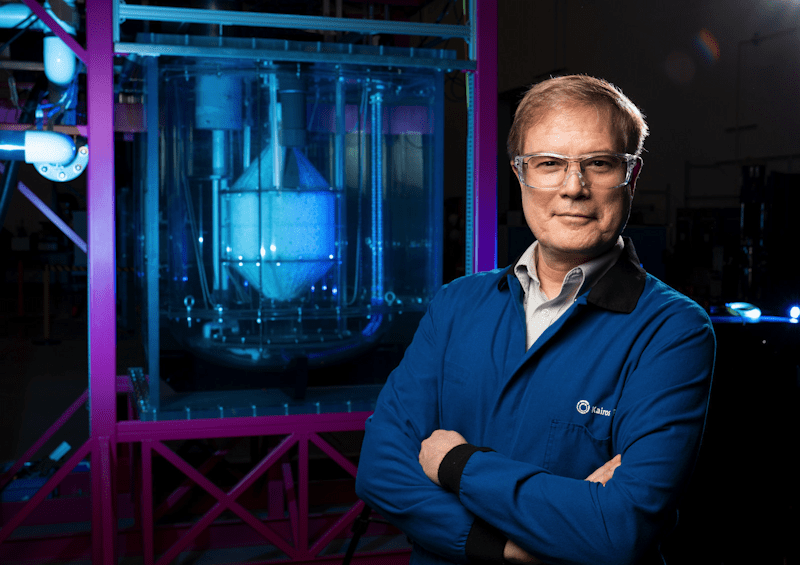

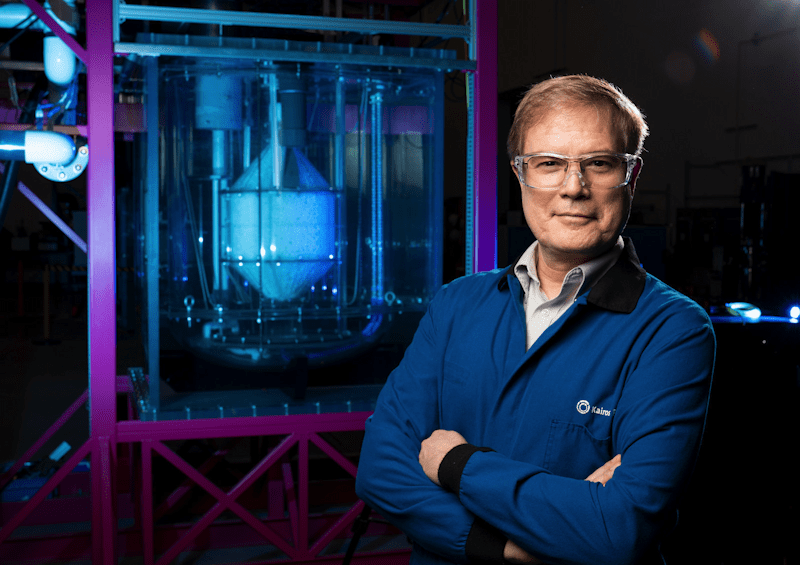

Atomic Show #288 – Per Peterson, CNO, Kairos Power

Image provided by Kairos Power

Kairos Power Is developing a truly new nuclear fission power technology. Their KP-FHR (Kairos Power – Fluoride Salt Cooled, High Temperature Reactor) combines the solid fuel form usually associated with gas-cooled reactors with the fluoride molten salt often associated with fluid-fuel reactors.

For Atomic Show #288, my guest was Dr. Per Peterson, Kairos Power’s chief nuclear officer (CNO). Per explained the technical logic leading his company to make its ground-breaking choices.

Before describing process of making technical choices, Per provided a brief summary of the KP-FHR technological development history. The FHR originated in a conversation with MIT’s Dr. Charles Forsberg and later became the subject of an integrated research program between MIT, University of Wisconsin, and Dr. Peterson’s academic home at University of California’s Berkeley campus.

As Per was careful to point out, the program was primarily funded with Department of Energy (DOE) academic research grants and involved a number of both graduate and undergraduate research students from each of the participating institutions.

This type of project grant program is aimed at giving students practical design experience and providing purpose for experiments, equipment design and testing. Sometimes, as in the case of the FHR, members of the research team recognize that they have a product that can be commercialized because it has characteristics that are superior to similar products in the market.

Three members of the FHR integrated research project team, Per Peterson, Ed Blandford, and Mike Laufer founded Kairos Power in 2016 as a venture-funded Silicon Valley company to refine their ideas and commercialize the technology they had helped to develop within the academic setting.

In 2018, I talked with Ed Blandford and Per about Kairos Power, this show is part of my promise to provide updates on an intermittent basis.

Brief description of the KP-FHR

The nuclear fission heart of the KP-FHR is a pebble-bed reactor with 4 cm diameter fuel elements that each contain thousands of TRISO fuel particles in a graphite matrix. Fission heat generated in the reactor is moved by a pumped flow of fluoride salts through a heat exchanger that transfers the fission heat into nitrate salts similar to those used in concentrated solar thermal power systems.

The nitrate salt is pumped through a second heat exchanger (steam generator) that functions as a water boiler to produce steam with temperature of 585 ℃ and pressure of 19 MPa. As Per explained, that combination of temperature and pressure is equal to the most modern coal fired steam plants.

In fluoride salt the fuel elements have a slight positive buoyancy. To provide long operating periods without a large amount of excess reactivity at the beginning of core life, the KP-FHR includes an online fueling system that removes pebbles at the top of the core and replaces them with fresh or slightly used pebbles at the bottom.

The pebbles move slowly and have very low frictional contact with each other in the bath of molten salt. The reactor operating temperature is approximately 1000 ℃ lower than the temperature at which the TRISO fuel particles would begin releasing even small quantities of fission products, giving the reactor a broad thermal margin. As Per described it, the pebbles are so relaxed that they are almost meditating during their residence time in the molten salt.

What happened to the gas turbine concept?

Some listeners might remember that Kairos Power initially planned to use a Brayton cycle heat conversion system with the potential for using natural gas co-firing to produce peak power. Like many academic ideas, the system that looked good on paper or on computer screens turned out to be more complex and difficult to develop than expected. The current design is the result of numerous studies done with both technical and market parameters included.

Per provides a more complete version of the story and also shares the excitement that comes from working with a large, growing team of talented and motivated technologists.

What is Kairos Power’s near term plan?

One of the more exciting developments that Per shared was the fact that Kairos has been selected as a recipient for a grant under the DOE’s Advanced Demonstration Reactor Program (ADRP). Kairos will be filing a construction permit application in approximately one year to build a reduced scale version of its KP-FHR that it calls the Hermes project.

The project will be constructed on a site at the East Tennessee Technology Park near the Oak Ridge national laboratory.

DOE has promised to provide a little more than $300 million over a five year period (subject to future appropriations); Kairos will provide at least a 1:1 match of that DOE money for a project total of a about $600 million.

As might be expected, Kairos hiring and will continue to expand as it moves past laboratory scale and into a nuclear construction project.

I hope you enjoy the show. As always, comments are welcome. The conversations here often stimulate new ideas and thinking.

Podcast: Play in new window | Download (Duration: 49:09 — 56.4MB)

Subscribe: RSS

This is a superb interview.

I rarely have the patience to listen to podcasts, but I listened to every minute of this one. Not only is Dr. Peterson a top professional in his field, he’s a wonderful communicator. And you could tell both he and Rod were enjoying the conversation.

It was a privilege for this semi-informed laymen to listen in.

I agree with Huon.

Next time ask about costs like Flibe cost, rebar construction costs, and cost per pingpong ball sized fuel balls. Oh, how many balls?

Excellent questions. The best non-proprietary estimates for Flibe and for rebar inputs for FHRs is in the Mk1 Final Design Report, http://fhr.nuc.berkeley.edu/wp-content/uploads/2014/10/14-002-PB-FHR_Design_Report_Final.pdf. For KP-X fuel, the recent National Academies presentation gives quantitative information, https://www.nationalacademies.org/event/01-11-2021/docs/D45ACC785C0E01A2B174C9167BD66E1176F19060C51A. For KP-X, each 1 foot diameter, 6 foot tall used fuel canister can hold 2100 pebbles, producing electrical power equivalent to burning 72 railcars with 120 tons of coal each.

Per:

Thank you for sharing the references. The table on page 16 of the NAS presentation includes a footnote “PBMR, 4-loopPWRandS-PRISMvaluesfrom”TechnicalDescriptionofthe‘Mark1’Pebble-BedFluoride-Salt-CooledHigh-TemperatureFluoride-Salt- Cooled High-Temperature Reactor (PB-FHR) Power Plant,” UC Berkeley, Report UCBTH-14-002, 2014.”

Can you share that report or tell me where I might be able to find it? I’m curious about the PBMR values.

Enjoyed the podcast. Always great to listen to people who know what they’re talking about! Dr. Peterson is that rare gem of both an expert on many fields and a good communicator. Kairos is lucky to have him.

Being a thermal-hydraulics guy myself I’m very impressed also with Dr. Peterson’s related research work.

Which brings me to my question – has full-power natural convection core flow been seriously considered? The salts have good natural convection properties, owing mainly to the quite large density change on heatup, giving a high driving force when paired with the large allowable dTs possible with fluoride salt coolants.

Some quick calculations show this to be quite feasible, given the low power density core (higher than PBMR, but much lower than NuScale) and small reactor size. Even with a quite large reactor (for SMR definitions) it should be quite feasible given a short flow path length, which is feasible in various ways. The reactor could be of a radial flow or mixed radial/axial flow type for example, with a radial flow HX, or possibly a “pancake” type HX such as commonly used by the automative and HVAC industries etc. The HX would be a bit bigger of course, as the convection coefficient would be lower on the primary side, but this likely has only modest impact on cost and would be offset by no pump and pump power costs, not to mention no pump development and qualification/endurance testing costs and related project timelines.

Removing the need for a primary pump has some serious advantages, such as eliminating pump transients/accidents, generally simplifying the plant design, and importantly avoiding the need to design and qualify a pump to run for decades in molten salts, or provisions to repair the pump (given the toxicity of beryllium fluoride and the large tritium inventory this would be a non trivial task).

Perhaps Dr. Peterson could comment more on this. To me it seems like an obvious avenue of investigation for the particular reactor size and application envisaged.

Rod, you can find the PBMR reference on page 33, http://fhr.nuc.berkeley.edu/wp-content/uploads/2014/10/14-002-PB-FHR_Design_Report_Final.pdf

Cyril this is an excellent question. The Mk1 PB-FHR provides a good, nonproprietary case study. Natural circulation is excellent for decay heat removal in pebble-bed FHRs. One can reduce flow resistance with radial flow (short flow path) in the core, but this raises other issues. Forced circulation ends up being the best approach for power operation for simpler core geometries, but the circulating power input is still quite small compared to most other reactor types. The key issue for natural circulation is the set of incentives to have the heat removal heat exchangers be at an elevation comparable to the reactor vessel, so the elevation difference available to drive natural circulation at full power is limited. Given a decision to use forced circulation, one wants to then maximize the benefits including capability to control flow rate with variable frequency drive.

Huon is 100 percent correct.

Years ago I had one nuclear engineering course while attending college. That ever a very boring class. If Dr. Peterson had been my instructor years ago, it may have taken me a lot less time to realize its value.

From what I could see, the Terrestrial MSR offers the best opportunities to try out your idea, and offer easy replacement and disposal of heat exchange apparatus.