Russia continues sustained fast breeder reactor effort

On June 26, 2014, the 60th anniversary of the start of the 5 MWe Obninsk reactor that was the first reactor in the world to routinely supply electricity to a commercial power grid, Russia started up the latest in a series of sodium-cooled fast reactors, the BN-800.

This new nuclear plant is an evolutionary refinement of the successful BN-600 that has been operating in Russia since 1980 and “is said to have the best operating and production record of all Russia’s nuclear power units.”

Here is a quote from a promotional brochure about the project published in 2011 by Atomenergoproekt, the joint stock company that built the power plant.

BN-800 power unit (under design) for Beloyarskaya NPP accommodates all principal concepts and solutions used in its predecessor BN-600, substantiated by over 20 years of its successful operation at high performance (capacity factor 80% at efficiency 42%).

BN-800 Power Unit is designed primarily for the production of heat and energy. The Power Unit as part of the grid operates with constant rated load (basic mode).

However, BN-800 characteristics and physical features dictate its multi-purpose usage. Viz, the reactor is used for:

- electric and heat power generation

- plutonium consumption and, if necessary, production

- processing of long-lived supertransuranics accumulated in the radwastes of reactor of any type

- production of isotopes.

No other reactor type combines so wide a range of functions.

Equipment of the reactor and its system involved in the handling of fuel assemblies containing isotopes and supertransuranics is designed to perform the above-mentioned functions.

The system builds off some of the successes of fast reactors designed and operated in Russia and the rest of the world and also incorporates features that avoid some of the characteristics that have led to failures in fast reactor programs. In other words, the BN-800 is the result of learning and the progress that can be made with sustained effort in any challenging, but potentially rewarding field of endeavor.

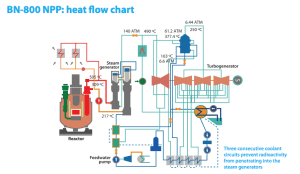

As shown in the below process heat flow diagram, the BN-800 uses a large pool of sodium and three separate heat transfer systems to provide passive safety. This is a concept that is similar to the one that was well-proven in more than 30 years of operation and testing at EBR-II and at previous BN-series reactors.

The BN-series reactors continue to use oxide fuels because they have achieved reasonably good results with that type of fuel and the responsible designers do not see any compelling reason to change. My friends who remain strong advocates of the Integral Fast Reactor have convinced me that a new fast reactor program started today should carefully consider the use of metal alloy fuels because they enable the use of an improved pyroprocessing technique for recycling the used fuel rods. It would be more difficult for a program that has a large investment in the capital equipment and human knowledge required for manufacturing and recycling oxide fuels to make that revolutionary technology choice.

While reading a terrific biography of Leo Szilard titled “Genius in the Shadows”, I found the following quote that illustrates the confused view of nuclear energy that is prevalent among the portion of the American intelligentsia that write books and perform historical research and commentary. It is relevant to this story about incremental progress in fast breeder reactor development.

Szilard’s faith in the peaceful benefits of atomic energy has certainly been rewarded in the development of medical technology, although his hope that nuclear power would help developing countries to prosper has proven impractical. Overstated, too, was Szilard’s faith in his breeder reactor, which has proven to be a dangerous and costly electricity producer in every country that has tried to build one.

My answer to the author of that passage is that virtually every technology ever devised by man would have been considered a costly failure if the inventor gave up after trying to “build one“. As the old schoolyard saying goes, “If at first you don’t succeed, try, try again.”

In the foreword to _Plentiful Energy_, Till & Chang’s book about the integral fast reactor, Barry Brook compares the IFR to the Wright Flyer. He notes that is took many decades of failures & partial successes before the Wrights made an aircraft that worked. Brook sees the IFR as similarly the breeder reactor that learns from all the previous failures to get it right.

My first reading of your post left me with the impression that the Wright brothers spent decades before their first 1903 flight. It seems that they started after Otto Lillienthal’s death in 1896. Building on the work of their predecessors and doing their own research on the behavior of airfoils, they applied the newly invented gasoline engine and developed their propeller and aircraft controls.

Where is France on those lists with Phenix and Superphenix?

Super Phenix

http://econtent.unm.edu/cdm/singleitem/collection/nuceng/id/2/rec/3

@JohnGalt

And in the case of Russia, China and India, the programs are continuing in earnest.

I cannot speak for the UK, Japan, Germany or Italy, but I have a pretty fair understanding of why the US program cost so much money and made so little progress. A good bit of the blame can be laid on the doorstep of a single man who stubbornly thought he was the second coming of Rickover and refused to pay attention to those who tried to tell him he was pursuing a bad technical direction.

Of course, Shaw also received some obsequiously glowing reports from the contractors that were on the receiving end of his stubborn insistence that fast breeders should use a loop type coolant system, single tube steam generators and oxide fuel.

I think this is a little too convenient an “explanation” for the failure of the breeder (or liquid metal reactor) in the US–in the sense of commercialization. The “loop” concept pretty much died with the demise of the Clinch River Breeder Reactor; since that time, the reference design for US R&D on LMRs has been a pool configuration with metal alloy fuel. (Though it should be noted that, even if it was not a power reactor, the loop-type FFTF did operate quite well during its all-too-brief lifetime.)

There are lots reasons for the lack of progress in developing a commercial LMR in the US. The on-again, off-again policy with regard to closing the fuel cycle (it makes little sense to deploy breeders if you’re not going to reprocess); lukewarm political support for much of the past 30 years; and that old standby, economics. This is also a case where the US regulatory system has had a dampening effect: the current set of LWR-oriented regulations is challenging to adapt to LMRs, and the NRC has not shown a lot of enthusiasm for doing so. (If you look at the countries where the work is “continuing in earnest,” their regulatory systems are somewhat more flexible. But those are also countries where the government takes a hand in building the plants and regulating them, a practice that can lead to compromises in safety.)

I spent the first part of my career working on LMRs, and I still like the technology. But I don’t see a technical or economic case being developed for LMR deployment in the US for at least another 15-20 years, and it may not happen that soon. The only way that I can see it moving faster is if Congress were to make it a national priority, and provide the funding needed to bring the technology to market and to make the necessary changes to NRC regulations. And it’s hard to see that happening, given the current poisonous political atmosphere in Washington, D.C.

@oldnuke

You’re right. The explanation is more complicated and the factors that you mentioned all had important roles to play.

The reason I put so much blame on Shaw was that the program he ran cost a great deal of money and produced no results. When people then “adjust” the dollars spent on the Clinch River Breeder Reactor for inflation, they can successfully portray what appears to have been a large effort that failed, thus “proving” that liquid metal breeder reactors are not a viable development path.

They aren’t viable if we prohibit recycle – so we should not prohibit recycling. They are not viable under NRC light water-centric regulations, so we should push for regulatory revisions. They are not going to succeed in the US given the current poisonous political atmosphere in Washington, but if we cannot change that atmosphere, very little will succeed in the US.

I’d like to see several PRISMs built so we can gain experience, prove that used nuclear fuel is valuable raw material, and learn whatever else we need to learn to develop LMRs into a reliable and affordable technology option. (I feel the same way about liquid fueled breeder reactors.)

PS – The ideal way to fund this effort is to make it very clear to the multinational petroleum companies that if they want to continue dominating the energy business, they had better figure out how to successfully use their capital to become good at nuclear technology. Back in the 1950s, one of the most successful tactics was for people like Al Gore Sr. to tell private energy companies that the government would develop nuclear power plants if they continued to refuse to invest.

Wow, that is some rich irony. What a contrast between what Al Gore Sr. did and what his son AG, Jr. has done, both with the killing of the IFR development during his Vice Presidency (1994) and with shining more light on the global warming/climate change issue than almost anyone (with the film “An Inconvenient Truth”) while simultaneously being generally opposed to what would be far and away the best solution to the issue (atomic power, of course).

@Joel Riddle

You might enjoy reading a piece I wrote almost 20 years ago http://www.fee.org/the_freeman/detail/the-first-atomic-age-a-failure-of-socialism.

It mentions Al Gore Sr.’s role in promoting nuclear energy.

Not to imply that the IFR killing was anything close to being solely Al’s decision.

Also, it should be noted that Watts Bar Unit 1 reached commercial operation during Al Gore’s Vice Presidency.

http://fortune.com/2014/06/27/government-watchdog-u-s-slipping-in-nuclear-energy-innovation/

“The driver here is not the technologies, but the political will,” said ANS’ Brady Raap.

DOE stopped developing a high temperature, gas-cooled reactor in 2011 because it was unable to agree to cost sharing with industry after spending over $500 million.

Carlgh Comment:

GenIV International Form (GIF) was initiated by DOE in 2001 with six reactor types. DOE selected the Sodium-cooled Fast Reactor (SFR) as the GenIV reactor type to go forward. Following the Energy Policy Act of 2005, Global Nuclear Energy Partnership (GNEP) was formed around the SFR “Burner Reactor” with the recycle of used fuel.

Politics got involved with Idaho and the DOE labs. So with a slight-of-hand, the Idaho based – Next Generation Nuclear Plant (NGNP) became the DOE GenIV reactor type project of choice. GenIV’s very-high temperature gas reactor (VHTGR) uses helium as a coolant, renamed NGNP. This GenIV reactor has sex appeal for the manufacture of hydrogen, if hydrogen were to become a green transportation fuel. NGNP has difficult material, construction and containment issues due to the high operating temperature of the helium gas that tries to leak-out everywhere. NGNP has issues at the NRC, huge cost & delay, no industry partner, and political ill-will. So DOE-NE is left with an empty bucket.

Aside: A DOE awarded study published in April 2007 (to support the GNEP EIS) stated that Fast Flux Test Facility (FFTF), SFR test reactor, could be restarted in 5 years at a cost of $500 million. The draft GNEP EIS was dead-on-arrival at Obama’s DOE. End aside:

There has been some progress in modifying design guidelines so that advanced reactors and small reactors can be licensed (if I summarized this correctly); my info is from the links/downloads in this thread:

http://www.energyfromthorium.com/forum/viewtopic.php?f=50&t=4358&start=0

Perhaps there is room for hope, after all.

@oldnuke

Thank you for you assessment of the near future of liquid sodium reactors. One thing that is not happening is liquid sodium R&D projects emerging from the private economic sector,. In contrasts three privately financed MSR projects are underway in North America and another is waiting in the wings in Japan. In addition, a very large government financed MSR R&D program is underway in China.

@Charles Barton

How does the size of the “very large government financed MSR R&D program” in China compare to the size of their LWR construction program, their HTR-PM demonstration project which is following their HTR R&D program, and their fast breeder reactor construction program using BN-series technology purchased from Russia?

http://www.world-nuclear.org/info/Country-Profiles/Countries-A-F/China–Nuclear-Power/

I have no qualms about MSR technology development. I’m cheering for the privately funded projects that you mention and even providing some assistance to more than one when approached. As is well proven, I like light water reactors. I’ve been an active member of an IFR community group for several years. I believe our government needs to enable far more variety in technical approaches and should look north to find a real “gold standard” in nuclear regulations and the gold standard in leaders of a regulatory body.

Aside – Here is an example of how a regulator with courage and strength of conviction should handle a public meeting where antinuclear activists get out of control.

http://www.vice.com/en_ca/read/activists-are-lashing-out-at-the-canadian-nuclear-safety-commission End Aside.

I’m a fission fan. It is a viable combustion replacement and there really is plenty of money in the energy business to develop a number of different paths so we do not hitch our wagon to just one way of doing things again. Within each technology path, however, I advocate a complete understanding of the value of standardization and series production. The least economical type of production is one-of-a-kind.

Why is Argonne National Laboratory seldom mentioned in the

development of fast neutron breeder reactors. They were the

pioneers in this technology. Does anybody remember their

breeder reactor and their project leader Enrico Fermi?

@Kenneth

If you are interested in more breeder reactor history, please see

https://atomicinsights.com/pursuing-the-unlimited-energy-dream-some-history-of-the-integral-fast-reactor/

https://atomicinsights.com/recalling-the-integral-fast-reactor-ifr-passive-safety-experiments/

https://atomicinsights.com/cloistered-nuclear-scientists-needed-sun-tzus-advice-know-your-enemy/

https://atomicinsights.com/responses-to-brc-on-americas-nuclear-future-from-fast-reactor-experts/

https://atomicinsights.com/hydrocarbon-fueled-establishment-hates-idea-plutonium-economy/

http://www.osti.gov/includes/opennet/includes/Understanding%20the%20Atom/Breeder%20Reactors.pdf

There are more, but this reading list should get you started.

My answer to the author of that passage is that virtually every technology ever devised by man would have been considered a costly failure if the inventor gave up after trying to “build one“. As the old schoolyard saying goes, “If at first you don’t succeed, try, try again.”

In the first two decades of the atomic age, it was fairly common to physically build prototype reactors and acquire valuable nuclear know-how while doing so. Starting in the late 1970s, it became more common to model nuclear reactors on computers, and to study the most important aspects of new designs through detailed computer simulations.

Designers initially thought that using computer simulation would allow them to explore safely a greater range of advanced nuclear designs; more designs than we could ever find the means to physically build.

But over time, it seemed decade by decade we just built fewer and fewer physical reactors, as fewer and fewer good reactor ideas seemed to progress beyond simulation, get built, and become innovative new reactors.

I have repeatedly argued that Molten Salt Reactors offer several advantages over LNFRs. Most important is the superior scalability of MSRs, and the much higher cost of LMFBR start up charges. Safety is another issue. Both the IFR and the MSR are very safe, and feature passive safety solutions. The coolant for MSRs is safe but liquid sodium is not. My review of IFR research and development reports, suggests on going safety concerns for the IFR. A review of liquid sodium fast reactor safty concerns by Sandia National Lab, suggests the same thing.

Oxide fuel reprocessing is expensive, so the metal fuel of the IFR offers lower cost fuel reprossing compared to the BN-800. Metal fuels are potentially safer. than the BN-800 oxide fuel.

The Indians are planibg to produce about 5 Oxide fueled LMBRs during this decade, and then switch over to Metalic fuel breeders. S-PRISM was designerd to be a burner rather than a breeder, although it is capable of operating in a modest breeding range. In contrast, the Indians are planning a second generation LMFB, that uses metalic fuel, and produces both Plutonium and U-233. The U-233 can be used to fuel Heavy Water thorium thermal breeders. I have argued that the United States offer to work with india to jointly manage this potentially valuable technology.

I am far from being an enemy of the LMFBR, but I do encourage its advocates to look carefully at its limitations and consider its highest and best use. If anyone is interested in my perspective on LMFRs, I will be happy to offer links to Nuclear Green Posts.

I think Charles Barton does service in pointing out some of the serious safety issues of SFR safety (and to a lesser extent the historical demonstrated cost of SFR reactors).

The total inventory of radioactive nuclides in current Sodium Cooled Fast Reactor designs is LARGE. When operating in a closed fuel cycle Minor Actinide (MA) burning mode and possibly loaded with additional separated MA from LWRs and after being loaded with about 5X the Plutonium-U-238 startup fuel as a conventional LWR, the total amount of radioactivity present in the reactor is LARGE. Significantly higher than any other competing active reactor design (including LWRs, LFTRs, MSRs, etc.).

Sodium Liquid Metal coolant is also dangerous and there is a truly large amount of this coolant in modern pool style designs with “passive safety features”. None of the SFR reactor designers release information regarding the amount of sodium in their reactor designs, and this fact makes accurate third party safety analysis difficult. Those wishing to access the potential of a sodium fire/hydrogen explosion based on earlier SFR designs that did not include all of the passive safety features which significantly increases the size of the main sodium coolant pool, like the French Superphenix. The French Superphenix used 5500 metric tons of sodium for a 1.2 GWe reactor – exact figures have not so far been provided for other mature SFR designs like GE PRISM or BN-800, but scaling the Superphenix numbers is about the best analysts can do given the reticence of current SFR designers to reveal to the public and decision makers the numbers that would allow fair and accurate analysis of the potential hazard of the SFR designs they promote.

“Explosive Driving Force” Comparison (GE PRISM versus LFTR) –

A 300 MWe GE PRISM could produce a combined sodium fire/hydrogen explosion releasing 2.03 x 10^7 MJ of energy (estimate based on the explosive potential of 1650 tons of hot sodium and 803.4 million liters of hydrogen produced by reaction with cement or water)

A 300 MWe LFTR could not produce an explosion with materials found in the reactor or with water

2.03 x 10^7 MJ of energy from a combined sodium fire/hydrogen explosion is a lot of energy. I will stop short of making comparisons with other large explosions (Hiroshima) but suffice it to say that 2.03 x 10^7 MJ is LARGE, even relative to known large explosive events. A SFR sodium fire/hydrogen explosion may not produce the same blast effects as a nuclear explosive, but the potential for a really large explosive accident is always lurking with this SFR technology.

When you combine the largest radioactive inventory of all current reactor designs together with the largest stored energy in highly reactive sodium metal coolant, you have the potential for a LARGE accident.

The world will not tolerate an additional LARGE nuclear accident greatly exceeding the magnitude of any INES scale level 7 accident that has yet occurred. The safety of SFR technology, if built, would jeopardize the future of nuclear power generation. Safer reactor technology alternatives exist, including Thorium MSRs or DMSRs. When choosing a desirable nuclear future, safety should be our first consideration.

———————-

Sodium Safety –

Sodium reacts exothermically with liquid water or steam to generate sodium hydroxide

and hydrogen:

Na + H2O -> NaOH + 1/2H2 + heat

Heat of reaction: ~ 162kJ/mole-Na

(around 7.05MJ/kg-Na)

Hydrogen tends to accumulate in the roof area of a reactor containment building and if the conditions are right, hydrogen air mixtures can detonate.

Reference – G. Manzini and F. Parozzi “Sodium Safety”

https://www.thefpa.co.uk/mainwebsite/resources/document/sodium%20safety.pdf

Robert, Great comment.

@Robert

If you keep sodium separated from water and air, there is no explosive potential, no matter how much sodium there is in the system.

This is one more example of fratricidal FUD among fission fans who think their way is the only way.

It isn’t FUD, it is a fact of chemistry. Any incident would likely need to be intentional, but it is certainly not impossible, and the outcomes are truly frightening. (Let us not forget that nuclear has powerful enemies within as well.) A vat of salt by comparison is truly benign. There is no physical means for causing a significant dispersal, even if an MSR were bombed.

Either way, the more important practical issue is scalability. Fast reactors make poor use of fissile resources. It is more sensible to instead start 5-10 times as many MSRs or LWRs with the same fissile. When stocks of spent fuel and weapons surplus inevitably run out, they will require considerably less fresh mining as well. (Eventually none at all, beyond byproducts of other mining…)

The defense in depth of containment buildings makes them very “hard” targets for attack. Other features like intermediate coolant loops provide physical separation between the main sodium coolant pool and any substantial source of water. Passive convective cooling of the reactor proper means that shutdown is the end of the issue; nothing else needs to be done from that point forward to make the system safe.

“None of the SFR reactor designers release information regarding the amount of sodium in their reactor designs, and this fact makes accurate third party safety analysis difficult. ”

Sure they do. The BN800 has a primary coolant inventory of 910 tons, for example:

http://www.spbaep.ru/wps/wcm/connect/spb_aep/site/resources/6d77898047832831a7a9ef9e1277e356/BN-800_2011_EN_site.pdf

Found by googling ‘BN800 sodium inventory’…

One thing that I failed to mention about liquid sodium nuclear technology is that it frightens me. Liquid sodium is inherently dangerous, and a major LSFR accident would be a huge blow to the future of nuclear technology. LSFR accidents may be rare, but they are not impossible. We need to weigh the risks and benefits carefully.

A bit of contradictory logic. Of course “We need to weigh the risks and benefits carefully.”, but statements like “Liquid sodium is inherently dangerous…” and “One thing that I failed to mention about liquid sodium nuclear technology is that it frightens me.” are entirely qualitative and/or subjective and entirely unhelpful to the discussion.

@Charles Barton

Live steam is inherently dangerous. It was implicated in numerous fatal accidents, many of which received front page coverage by the mass media of the mid 1800s. Then the American Society of Mechanical Engineers and the Hartford Steam Boiler Insurance Company cooperated to establish detailed standards for high pressure boilers and piping systems. Using ever improving techniques, we have virtually eliminated boiler explosions and steam pipe ruptures as a significant cause of human misery. That does not change the basic premise that live steam is inherently dangerous, but it does allow us to use it as a valuable tool to make lives better.

https://www.hsb.com/HSBGroup/History.aspx

By the way – live steam frightens the heck out of me if it gets out of its containment systems.

Aviation is inherently dangerous. It is also one of the safest ways to travel.

Live steam does not contaminate vast swaths of the countryside for centuries (or millennia) if it escapes its containment. It may cause local injury or death to local operators, but will not harm anyone or anything else, as it is water vapor and harmlessly disperses into the atmosphere. Big difference.

@Harm

And what part of a sodium cooled reactor has the ability to contaminate vast swaths of the countryside for centuries? As is the case for molten salt reactors, sodium cooled reactors operate at low pressure and don’t have a driving head that disperses the material. Granted that if an interaction with water occurs, there can be an explosion, but containments can be designed. In fact, the very first containment vessel I ever entered was designed to contain the worst case even in a sodium cooled reactor. That containment had been repurposed and held a water cooled reactor at the time I worked there.

There is sufficient experience in the handling of sodium as a reactor coolant to understand that it does not pose grave dangers if it leaks. The fires that have happened have been contained and extinguished without difficulty. One thing that many seem to forget about sodium is that it requires substantially higher than “room” temperature to remain a liquid. When it leaks out it tends to cool and solidify.

For all of the people with a serious interest in this topic, I highly recommend reading “Plentiful Energy,” which was written by people with direct physical experience with liquid metal cooled reactors, not just experience in reading scary, worst case analysis by people that were already convinced they did not like the idea of sodium near water.

@ HARM. No, but FUD does. It causes the death of millions and impoverishes the masses.

Perhaps Rod misinterpreted your bent. I think the chances of your picking up “Plentiful Energy” are about NIL, unless you ever decide to actually seek some technical expertise, which *will* force you to nuance your fears. If you ever do seek such knowledge, then “Plentiful Energy” is a good way to gain deep understanding of IFRs. Best to you sir.

Rod, Not only is steam dangerous, but assuring the safety of reactors that produce steam is also dangerous. A loss of coolant accident will lead to emergency cooling procedures. If not brought under control we can see hydrogen explosions as a consequence of water cooled accidents, witness Fukushima. But as bad as the consequences of a loss of water coolant accident are, the potential consequences of a loss of sodium accident are much worse.

This Sandia literature Review tells the story.

http://prod.sandia.gov/techlib/access-control.cgi/2007/076332.pdf

Rod, I agree with what you say about live steam, but nore that is expensive to make steam safe, and that virtually is not the same as always. Obeying the rules of nature is the way to do it always. Steam means finding ways to get around the rules of nature.

I believe that all fast neutron solid fuel reactors should be immediately shut down and defueled, because they have not been proven safe against high reactivity rate super prompt criticality accidents, by fundamental principles of physics. We have discussed this before.

https://atomicinsights.com/plutonium-power-for-the-people/#comment-26731

https://atomicinsights.com/kirk-sorensen-why-didnt-molten-salt-thorium-reactors-succeed-the-first-time/#comment-14957

Here is an interesting video of the destruction of the BORAX II reactor by a super prompt critical burst.

https://www.youtube.com/watch?v=8WfNzJVxVz4

Here is an essay providing a FASCINATING inside view of the project. In addition to info on the BORAX project, it touches on the EBR-1 meltdown, the politicization of nuclear R&D, and the importance of good public relations.

http://www.ne.anl.gov/pdfs/reactors/Story-of-BORAX-Reactor-by-Ray-Haroldsen-v2.pdf

Rod Adams interviewed the author here.

https://atomicinsights.com/atomic-show-68-ray-haroldsen-atomic-tinkerer/

Now imagine running this experiment using a BN-800 core, which is different in many ways.

1… 120 tons of fuel.

2… 20% enrichment vs. 5%

3… Sodium coolant vs. water coolant

In water moderated reactors, neutrons loose speed colliding with hydrogen and oxygen atoms making them more likely to be captured by a uranium atom. In fast neutron reactors the density of fuel atoms is high enough that a fast neutron is likely to be captured and cause a fission before it leaks out of the system.

In a fast neutron reactor, neutron lifetime is about 1000 times shorter than in a thermal reactor, making extremely fast power rise times, and nuclear explosions, possible.

As water is ejected from a thermal core like BORAX II, the average neutron speed increases, reducing the probability that a neutron will cause a fission, thus reducing the multiplication factor and ramp rate of power, slowing and eventually terminating the pulse.

Sodium is a weak neutron absorber. As sodium is ejected from the core of a solid fuel fast neutron reactor, it makes more neutrons available for fission, accelerating the ramp rate of power, the exact opposite of what is desired.

Supporters of solid fuel fast neutron reactors claim that they can probably contain a very low reactivity rate criticality accident, but they have not analyzed a high reactivity rate accident, and they have not proven that a high rate accident is impossible.

I believe that a high reactivity rate criticality accident in a solid fuel fast neutron reactor could vaporize the entire core and eject it into the atmosphere, creating an accident an order of magnitude or more worse then Chernobyl. This would harm billions of people, not from radiation, from killing nuclear power for another generation or two.

Solid fuel fast neutron reactors are complex machines requiring a great deal of time and money to build and maintain. Their kWhr’s will be expensive even if the uranium cost is negligible.

Simple molten salt reactors can be mass produced at low cost and operated in such a way that the waste stream is only fission products, waste storage time less than 500 years, by recycling plutonium and other actinides until they fission. They use uranium more efficiently than conventional reactors, making sea water uranium affordable and unlimited for at least a few hundred years.

Why make a Faustian bargain when there is no upside to the bargain?

I support R&D for fast and thermal neutron molten salt breeder reactors because I believe they can be proven safe from high energy criticality accidents from basic principles of physics. Fuel atoms and coolant atoms are mixed on the atomic scale, and I see no way to rapidly eject the coolant atoms and concentrate the fissile atoms.

To prove fast neutron solid fuel reactors are safe, model an accident that envelopes all possible criticality accidents. Start with a core early in startup, very low power, K slightly above 1.0 now crush the core into a pancake in 0.1 seconds, squeezing out all the sodium. If the resulting energy burst is reliably contained I’m satisfied. Feel free to do this with a well designed water moderated reactor or MSR (fast or thermal).

@Bill Hannahan

Since you reference Ray Haroldsen’s story about blowing up BORAX, I presume you actually read it. Do you recall the portion where he described in detail the creative engineering he had to invent in order to cause the rod ejection, high reactivity rate to begin in the first place?

There are many protections that prevent such an even from happening in any reactor that can be licensed and built today.

Rod wrote. “There are many protections that prevent such an even from happening in any reactor that can be licensed and built today.”

Rod, here is a summary of reported criticality incidents in the U.S. There have been many more around the world.

http://abomb1.org/accident/critical.html

If we had a time machine and went back before each accident and described the incident to the people involved as a hypothetical event, I think most would be dismissive, perhaps even annoyed at the suggestion that they or their people would let such a thing happen.

If we interviewed the TMI crew before the accident, they would scoff at the idea that a relief valve could cause a meltdown, pointing out that they have enough emergency pumping capacity to handle a double ended break of the largest pipe on the reactor six times over.

There is a misperception that there is a huge difference between a reactor running at steady power, on delayed neutrons, and a reactor on a very short period on prompt neutrons alone. In reality, there is a very narrow band of multiplication factor separating those two regions, especially in a fast neutron reactor where delayed neutrons are fewer and the consequences of getting into the prompt region are potentially much more severe. Ejecting a massive control rod is not the only way to add a lot of reactivity to a core.

Consider page 18 of this report, Fig. 3.3, showing that the Phenix reactor experienced 5 big reactivity and power swings in 1/3 of one second, due to a phenomena that was and is still unknown to the designers.

http://uu.diva-portal.org/smash/get/diva2:402326/FULLTEXT01.pdf

This graph alone should shake your confidence in solid fuel fast neutron reactors. It is natures way of telling us we are on risky ground here.

Here is a report describing the work that needs to be done to build a future solid fuel fast neutron reactor. It does not say much about criticality safety, but all the issues discussed impact criticality safety.

http://www.plinius.eu/home/liblocal/docs/May2014%20seminar%20presentations/11%20-%20PLINIUS2_CEA%20Roadmap%20for%20SA%20ASTRID_V2.pdf

Reading between the lines, it is clear that these things are not fully understood today. So why take the chance just to make expensive kWhrs in an expensive complex machine that takes a long time and a lot of money to build?

@Bill Hannahan

If we interviewed the TMI crew before the accident, they would scoff at the idea that a relief valve could cause a meltdown, pointing out that they have enough emergency pumping capacity to handle a double ended break of the largest pipe on the reactor six times over.

The stuck relief valve didn’t cause the TMI meltdown. The underlying root cause was that conventional wisdom did not recognize that a small leak in the steam space of the pressurizer would inevitably make indicated pressurizer level INCREASE rather than decrease. If simulators had been properly programmed and training modified after the 1977 precursor at Davis Besse, TMI would have never happened.

I agree Rod. Direct level indication in the reactor vessel would also have prevented the accident.

The point is that designers and operators can never be assured that they have covered every possibility. That is why inherent safety by fundamental principles of physics is most desirable.

@Bill Hannahan

The point is that designers and operators can never be assured that they have covered every possibility. That is why inherent safety by fundamental principles of physics is most desirable.

Bill – please read your own statement and think very carefully about the notion that it is possible to design a powerful energy producing system that is completely safe.

IMO anyone who claims that “absolutely nothing can ever go wrong in MY system” just has not lived long enough or read enough.

The IFR type fast reactor can be safe enough; not perfectly safe, but safe enough to be allowed to provide many billions of kilowatt hours in beneficial production.

@ Rod Adams

Bill – please read your own statement and think very carefully about the notion that it is possible to design a powerful energy producing system that is completely safe.

Rod, it is beneath your usual standards to create a straw-man. The issue is about a class of reactors that might produce a nuclear explosion. See my response to EP below.

Thermal neutron reactors are protected against nuclear explosions (not steam explosions) by fundamental principles of physics.

The issue is not complete or absolute safety.

@Bill Hannahan

The problem I have with your position is that you have to propose mechanically fantastic effects to conclude that a reasonably well designed fast reactor is capable of a nuclear explosion. The series of events might be possible in some other world; you have not convinced me that they are even remotely possible on earth.

Rod wrote;

The problem I have with your position is that you have to propose mechanically fantastic effects to conclude that a reasonably well designed fast reactor is capable of a nuclear explosion. The series of events might be possible in some other world; you have not convinced me that they are even remotely possible on earth.

Rod, it is amazing to me that you can dismiss the handwriting on the wall so easily. Let’s review the evidence.

1. Hans Bethe calculated a very high energy density from a slow reactivity rate gravitationally induced criticality in a tiny fast neutron reactor.

2. The Phenix reactor experienced 5 big reactivity and power swings in 1/3 of one second, due to a phenomena that was and is still unknown to the designers. That is a huge red flag that these machines are sensitive, not fully understood and potentially very dangerous.

3. The Chernobyl reactor criticality accident released a great deal of energy. What would the yield be if that same amount of reactivity was introduced to a reactor with a neutron lifetime 1,000 times shorter?

I recall that you calculated that Fukushima released a few kg of cesium 137. What would the environmental impact be of dispersing 2 metric tons of Pu 239, 240, 241 in addition to a ton of fission products? Theoretical calculations claiming 10E-7 probability for this class of accident are not good enough.

4. NUREG-1368 was written by people who believe in, support and were employed in the IFR project. Reading the report is a bit like watching the Wizard of OZ, except that in the report, we never get to see behind the curtain.

We do not know, details of the accidents modeled, details of the results, how potential deaths were calculated, margin for error of the code.

They did acknowledge up to 124 prompt fatalities, indicating an accident far worse than Chernobyl, from a low reactivity rate, gravitationally induced criticality accident.

While the prompt death toll at Chernobyl was over 30, those were needless deaths of firemen sent in out of fear, embarrassment and ignorance after the reactor was completely destroyed. They could have quickly set up unmanned spray nozzles throughout the plant, controlled from remote valves, to maintain a mist of water treated with chemicals to prevent recriticality and precipitate cesium, without prompt fatalities.

I admire the bravery of the firemen, but with good leadership, the prompt death toll from radiation at Chernobyl would have been at or near zero. So the worst case NUREG-1368 accident from a low velocity low reactivity rate criticality accident, is far worse than Chernobyl.

BORAX, SL-1 and Chernobyl are thermal reactors destroyed by criticality accidents. These provide benchmarks to test accident computer models for thermal reactors. Where is the benchmark for validating LMFBR accident codes? The results in NUREG-1368 could be far off the mark.

Before the world allows fast reactors to operate, we should dig two large deep holes at the Nevada test site, install full size LMFBR reactors, one ceramic fueled and one metal fueled, run them up to low power, K=1, and rapidly crush them. The result of that experiment will resolve the issue, one way or the other.

In reviewing the links I see that I did not respond to an interesting comment by EP; I’ll do so here since comments are closed there.

EP wrote; ” Hans Bethe analyzed the explosive potential of a fast reactor meltdown and came up with a worst-case figure of 160 kg TNT equivalent. This is about 670 MJ, or about 200 msec of full-power output of a 3.3 GW(t) reactor.

It would be a real mess inside the containment, but that’s where it would stay.”

Three points;

1. The reactor Bethe evaluated was 53 cm tall and 23 cm in radius, 91 litres. The Superphenix core was about 6,000 liters. Assuming the same energy per liter, the energy yield in Superphenix would be equivalent to 10,000 kg, 10 metric tons of TNT.

In a nuclear bomb core compressed to a few inches in diameter, a few thousandths of an inch diameter change makes a big difference in reactivity, yet a great deal of energy can be released in the short time it takes to disassemble itself. In a large irregular superprompt critical assembly, much larger dimensional changes are required to make the assembly subcritical, and that takes more time, allowing for more energy to be released.

Assuming the energy density in the criticality accident will increase in proportion to the volume of the core, the yield for Superphenix would be 655,000 kg, 655 tons of TNT.

2. Bethe assumed a slow, gravitationally induced reactivity insertion rate; I am concerned with a high speed, high reactivity rate criticality.

3. Large fast neutron reactors contain enough fissile material to produce hundreds of critical assemblies, yet proponents only discuss the possibility of a single low velocity criticality accident. What happens if a medium energy criticality creates a high velocity shock wave that crushes the remainder of the core in a few milliseconds?

Hes just being honest Brain. Its not a material that probably the most technical nuke engineer now would routinely encounter.

These reactors are part of the next step in the technology. More exotic materials and complexity really shouldn’t be such a turn off, but seen as more of a positive challenge to be overcome and then celebrated. That direction of complexity also does solve/address several important sustainability and safety issues.

In a very off topic note, but one related probably to climate, the upcoming holiday, and a area some of you reside/vacation in, and of course Rod you may it interesting : All the Ways a Hurricane Could Ruin Your Fourth of July Weekend ( http://www.slate.com/blogs/future_tense/2014/07/01/tropical_storm_or_hurricane_arthur_could_ruin_your_fourth_of_july_celebration.html )- Have a nice fourth all and stay safe out there.

Just on…the Russian movement toward Fast Breeders…Russia has an extensive plan for a nuclear build-out. Not as ambitious as the Chinese and Indian, but about 3rd in the world in new builds planned.

Rod has commented and I’ve always thought that such advanced plans by Russia had dual aspect of this, which is essentially to assure a supply of gas to sell to Western Europe, China and Japan. The more nuclear less gas they have to burn and more to sell. I think this has to be taken into consideration when discussing the Russian BN-800 (and larger models as well).

David

Very interesting article Rod, really enjoyed reading it and the comments. I wish other places had Russia’s confidence in rolling out new designs. I know China is getting ready for rollout of their PBMR — that’ll also be interesting if/when it happens.

It’ll be interesting to follow this machine’s performance — I wish they would put it on the web in real time.

I’m curious about who will use that 505 °C process heat, and what for.

@Steve Aplin

Thank you for the kind words. Did you see my earlier article about the Chinese pebble bed, designated as HTR-PM?

https://atomicinsights.com/htr-pm-nuclear-heated-gas-producing-superheated-steam/

Russian Bn-800 and Indian PFBR programs were running neck and neck but the Russians seem to have got ahead by a head. Indian reactor may now be six months behind.

IFR is the right concept for adequate power for the world but some sodium fires and halting at low hanging fruit of LWR seem to have stalled development of nuclear power in the US and NATO. It is proceeding steadily in rest of the world.

I wish some safer coolant like lead or salt mixture would have been selected for fast reactors instead of putting the program in abeyance.

Salt coolant reminds me that a Fast MSR with IFR reprocessing could be good option for recycling the LWR used fuel.

@Jagdish:

The “spent” fuel burning MSR links you are looking for are Trans Atomic Power Nuclear Reactor Design and TAP White Paper. This may be the most advanced MSR concept in the U.S., as TAP has commissioned Babcock & Wilcox to produce a working design.

Russia is the world’s leader in lead and lead-bismuth eutectic (LBE) reactor designs, and used them in their Alfa class submarines back in the bad old days. Russia maintains an LBE research program. However, there is good engineering reason for Russia’s choice of liquid sodium coolant for their BN-800 and its BN-1200 commercial follow-on: molten lead is corrosive, whilst molten sodium is a good reducing agent and very benign under reactor conditions. Commercial operations look for 60 – 80 year lifetimes for the primary components. Its a matter of reliability and safety.

WNN’s BN-800 page states that reactor is capable of operating with metal fuels, but mentions only oxides and nitrides for BN-1200. GEH has a fully developed and ready-to market metal fuel IFR design in PRISM, but has yet to sell one. Its a chicken-and-egg problem: GEH doesn’t want to pay the freight at NRC without a paying customer in hand, and paying customers don’t want to pay for something that is not yet fully licensed. ‘Cuz who knows how long that’s going to take?

Then there’s the matter of scale. At 300 MWe PRISM is a SMR that can only make economic sense if enough customers sign up for one to enable GEH to plan a mass production run. There’s also IFR’s fuel cycle and its fit with national fuel policy. At present U.S. policy — a relic of the Carter Administration — prohibits reactor fuel recycling. GEH and TAP are both pitching their wares to Congress as “spent” fuel burners that will (eventually) significantly reduce the amount of actual long-term civilian power waste. But its something that will require Congressional action 😮

GEH has similar proposal before Her Majesty’s Government, where it is under review. But Britain is a very different case: as part of the international non-proliferation program, they have taken upon themselves the task of reprocessing the world’s spent fuel and returning recovered Uranium and reactor-grade Plutonium to the countries of origin for reuse, along with vitrified HLW for disposal.

The Pu bit has been controversial, and a bit of a headache. U.K. has recently decided to-heck-with-it and will keep a good portion for itself — see UK increases control of civilian plutonium. Their current preference remains to burn the Pu as MOX fuel in their LWR fleet, but are open to other proposals if they offer better value to the UK taxpayer.

And that’s the bottom line. The unreliable contingent is vehemently opposed to any nuclear expansion and anything that smacks of — or can be contorted into — “unlawful government subsidy.” This is EU-wide, not just UK. Speaking of which, I see the Gang of Ten has formally petitioned EU Energy Commissioner Gunter Oettinger to please get serious about national energy requirements and their impact upon climate change.

“There’s also IFR’s fuel cycle and its fit with national fuel policy. At present U.S. policy — a relic of the Carter Administration — prohibits reactor fuel recycling.”

It’s no doubt a relic of that administration, but it’s a product of the Rand Corporation. A group who firmly believes every world problem must have a US military solution option. And they influence every administration to that end. Beware of anything flavored Rand.

@Rod Adams

Rod asked me several questions that I have failed to ask.

How does the size of the “very large government financed MSR R&D program” in China compare to the size of their LWR construction program, their HTR-PM demonstration project which is following their HTR R&D program, and their fast breeder reactor construction program using BN-series technology purchased from Russia?

Rod, The the MSR program in China originally envisioned a staff of aboiut 125 to 140 PhD level scientists, and I assume an equal number of PhD level graduate students, plus a significant skilled labor force. The total work force for the original 25 year project was to run to 750.

Recently the Chinese changed their time horizon for the LFTR to 10 years. This will require a significantly larger work force. As many as 750 PhD level scientists will reportedly be involved. The entire staff would probably be comprable in size to the entire staff of ORNL.

To replicate this very ambitious development program in the United States would probably cost ONR BILLION DOLLARS A YEAR FOR ABOUT 10 YEARS. This is not hugely expensive when compared with recent R&D costs for new lkong hall aircraft. and certainly far less than the cost of developing a new jet fighter.

The current Chinese investment in old technology nuclear plants, and the chinese have not been forth coming about their recent nuclear plant costs. The R&D programs for LMFTs is probably far more modest than for the MSR, and ditto for grtaphite gas cooled fast reactors. In both cases I have no reports that would help me to investigate the size of these programs and their costs.

From Ed Leaver-

‘WNN’s BN-800 page states that reactor is capable of operating with metal fuels, but mentions only oxides and nitrides for BN-1200.’

From reading ‘ Plentiful Energy ‘ I had the impression that experience with EBR II and the FFTF had pretty much sorted out the problems with metal fuel, but the French, the Russians and the Indians seem to be sticking with UO2, or working on carbides or nitrides. Also Fermi II switched from metal to oxide fuel after its mini-meltdown. The Korean Kalimer 600 is to use metal fuel, but why is everyone else so slow to adopt it? I know the melting point is lower, but with better heat conductivity, better neutronic behaviour, and easier processing, it should be possible to design around that. Is it just conservatism, with all the fuel fabrication plants and the licensing in place based on oxides?

@John ONeill

Perhaps the issue is that the people at Argonne who were involved in the IFR and solved the issues associated with metal fuels did not share all of the key details with all comers. Often there are very small differences between a successful design and one that does not work so well. That is the nature of “trade secrets.”