Experience Power with a healthy dose of microgrids, hydrogen and nuclear energy information

Each year since 1998, POWER Magazine has hosted a conference titled Experience Power that brings together utilities, suppliers, customers and energy leaders to discuss trends in the electric power sector. The event is currently organized as three colocated conferences, one focusing on electric power insights, one on distributed power and one on hydrogen.

The 2023 edition of the event was held in Savannah, GA, an appropriate and timely location selection. Several major construction sites surrounded the conference hotel and numerous large cranes could been seen downtown and at the rapidly expanding port up the river from town. Attendees that arrived at the conference from the west via I-16 described their awe at the scale of the construction activity at what I later learned was called the Bryan County Megasite. It’s where Hyundai recently began building a $5.45 B Megaplant. This massive new facility will have the capacity to produce 300,000 electric vehicles and to employ more than 8,000 workers.

Two weeks before the conference, Georgia Power, the utility sponsor for the event, placed Vogtle unit 3 into commercial service. The second new unit, Vogtle 4 should achieve the same milestone by the end of the first quarter of 2024. When the expansion project is complete, Plant Vogtle, just 60 miles up river from Savannah, will be the largest nuclear power plant in the United States.

Conference attendees were thus faced with looming reminders of the growing need for electricity to service expanding customer demand while also learning about new power sources that would help serve the needs of those customers for clean, reliable, abundant and affordable electricity for many decades.

The conference organizers at POWER chose to open this annual event with an afternoon of talks and panels focused on nuclear energy and its prospects for expansion as we strive towards a net-zero electricity grid. Most of the conference attendees worked outside of the nuclear energy sector of the electrical power business; they were treated to a set of facts and perspectives that they had not thought much about.

Project Vogtle Update

Jeremiah Haswell, the director of project oversight for Vogtle Units 3 & 4, provided an update on his project. Haswell arrived on the construction site in 2012, right after the expansion project received its Combined License. He experienced everything from the first nuclear grade concrete pour in early 2013 to its beginning of commercial operation at the end of July 2023.

Nearly every aspect of the Vogtle project was big. It was the largest construction project in the history of Georgia. Construction used the largest derrick crane in the world. Some of the modules lifted into the containment were equivalent to a five story building. The first of four steam generators lifted off the delivery ship set a record for the largest single lift in the history of the Port of Savannah at 680 tons. Its shield building supports a 750,000 tank of water above a steel containment dome, providing 72 hours worth of cooling without any additional water. It’s workforce peaked at 7,000 workers on site; more than 13,000 workers played a role at some time during the construction program.

Unit 4’s construction is complete. Acceptance testing will be completed sometime in the last quarter of 2023 or the first quarter of 2024. Once that unit is commercial, the Vogtle site will be the largest nuclear plant site and the largest generator of carbon free electricity in the United States. After both units are operating, nuclear will represent 1/3 of electricity in the state.

Haswell described the go, no-go uncertainty that the project faced in 2017 when Westinghouse declared bankruptcy. All four owners (GA Power, City of Dalton, Municipal Electric Authority of Georgia (MEAG), and Oglethorpe Power) had to agree to move forward. They needed permission from the Public Service Commission. Haswell extended his personal respect and gratitude for the courage of the commissioners. Tim Echols, the leading advocate for the project on the Commission, was in the audience and acknowledged the comment.

Those decision makers were motivated to push forward because they understood that the new units would be able to operate under almost any weather condition, they would produce carbon free power, and they would help to moderate fuel price impacts on customers. They also knew that operating Vogtle 3 & 4 would reduce ratepayer vulnerability to carbon prices, though the monetary value of that feature has been undercut by external political choices.

Even though completion was difficult and expensive, the new units will be adding their production to the grid at a time when it is in high demand. Georgia is growing, partly because power customers appreciate having steady, clean power. Haswell concluded his presentation by showing a short video highlighting an employee who grew up in the shadow of Vogtle Units 1 & 2. She raised her family in the same town and is proud to have been involved in building and operating the expanded plant.

New developments in nuclear from INL & DOE

Three speakers, two from the Idaho National Laboratory (INL) and one from the Department of Energy, talked about some of the new technological developments happening in nuclear energy. They acknowledged the important accomplishment of finishing the Vogtle project but also spoke about the ways that the new technologies were aiming to overcome some of the challenges faced by that trailblazing project.

Jhansi Kandasamy, the Director of the INL’s Net-Zero program, provided a talk that bridged interests across the individual conferences making up the main event. She is in charge of a program that is striving to achieve net-zero emissions for INL by 2031. She talked about micro-grids as part of a distributed generation system, about the usefulness of clean hydrogen in helping to propel zero emission vehicles and about the net-zero impacts of the purchased electricity delivered by an external utility. Emissions from purchased electricity represents more than half of INL’s total CO2 production.

She worked to persuade Idaho Power and Idaho Falls Power to consider adding nuclear power to their generating portfolio. It wasn’t easy since both have currently have some of the cheapest electricity in the country. During the persuasion phase, Idaho experienced a drought that reduced hydro output. Along with projected demand growth, both suppliers saw the need for new clean, firm power and have now agreed that they should strongly consider nuclear as part of their future generation.

INL has small and micro reactor projects that will be able to be integrated into a micro grid that will generate electricity, provide heat, and also produce hydrogen. The micro grid will be able to work with local utilities or as an island that only supplies lab loads. A micro reactor called MARVEL will be integrated into net-zero planning even though it will only generate 100 kWe. It will supply a vehicle charging station and a guard shack with power by the end of 2024.

Nick Smith is the deputy director of the National Reactor Innovation Center (NRIC). He gave a quick overview of INL projects and programs supporting nuclear energy, both for middle -aged operating reactors and for new nuclear power systems.

He mentioned support for integrated plant operations, accident tolerant fuel testing and the long term project to test and analyze performance for Triso fuels. He described how the MARVEL micro reactor project uses technology developed as part of the NASA Snap-10A and how Project Pele is a high temperature gas cooled reactor using Triso-based fuel in a system that is designed to be transportable with the primary mission of reducing logistics risks. He talked about lab facilities that are being repurposed by NRIC to support the demonstration of new reactor designs for private sector companies.

His favorite current project is the Molten Chloride Reactor Experiment (MCRE). It is a new reactor concept that has never before been tested. It uses a fast neutron molten salt reactor designed for online refueling and the ability be partly supplied with used nuclear fuel. The project will use a repurposed facility called LOTUS that has Level 1 safeguards controls. It is designed to use purified U-235 as the critical driver to make the system compact enough to fit inside the existing structures and to minimize the amount of waste material that will need to be handled after the testing is complete. The test program is designed to last just 6 months.

Primary goals for the project include confirmation of reactor kinetics and dynamics coefficients to verify models and simulations. It will help develop protocols for handling liquid fuels and to develop methods to verify fuel inventories and locations. It will stimulate supply chain development and produce high quality data that can be used to support commercial licensing. The project is being authorized by the DOE but the process includes participation by NRC employees to expand their ability to be independent regulators for commercial applications.

Smith is directly involved with the project’s fuel production. There is no direct experience to draw from, so the developers had to gather information from refining and recycling projects and experiments that use similar materials. The fuel synthesis program started with tiny quantities of just 10 gms of fueled salt and has now worked its way up to the full scale of 9 kg batches. It will take a lot of batches to produce the 1.3 metric tons of fuel salt needed for reactor operations. The core volume is roughly the size of a dishwasher. The reactor will produce just 100 kw of heat that will be absorbed by the building’s ventilation system.

As befitting a reactor whose purpose is to gather quality assured data, MCRE will be heavily instrumented. The project recently received an environmental impact finding of no significant impact, and has started procuring necessary equipment and materials. The fuel is already on site and full scale fuel synthesis is scheduled to be complete by the end of the next fiscal year (Oct 2024).

Mike Goff, the prinicpal Deputy Assistant Secretary for nuclear energy at the DOE, shared a long list of reasons why he is more optimistic about the future of nuclear energy than he has been at any time in his 35 year career at national labs and as a direct DOE employee. There is bipartisan and bicameral support in Congress, the Administration is strongly supportive and the Secretary of Energy, Jennifer Granholm, regularly describes the vital role that nuclear will play in the transition from near complete dependence on fossil fuels to a better energy system.

The DOE has several priorities, with continued operation of the existing fleet being at the top of the list.They want to keep deploying new reactors and are pleased to see that Vogtle 3 is now commercial with Vogtle 4 close behind. They’re helping to develop a secure and sustainable fuel supply with reduced dependence on unreliable suppliers. And they are expanding international cooperation with major efforts in Poland, Canada, the UK, and Romania with more to come.

The DOE’s nuclear energy budget has seen significant increases in the past few years. The Bipartisan Infrastructure Act and the Inflation Reduction Act have provided funding for programs like the Advanced Reactor Development Program (ARDP), the Civil Nuclear Credit program that provides production tax credits for operating reactors that are at risk of closing due to temporary market conditions, and added nuclear to the list of clean energy sources eligible for production and investment tax credits.

He described his recent appearance at a Congressional hearing where 28 representatives asked questions with none of them asking “why nuclear?” Instead they asked how they could help nuclear, most of them wanted to help nuclear projects move faster. He said that the industry has a great opportunity to prove it can deliver.

Regarding the operating fleet, he described how the DOE, industry and the Electric Power Research Institute (EPRI) are cooperating to ensure that plants continue to operate safely and reliably. Several have already received subsequent license renewals that allow the plants to operate for up to 80 years, but there is no reason to believe that is the ultimate limit. There is already discussion about the activities needed to enable operation to 100 yrs.

The DOE is supporting efforts to enable new revenue streams for both existing nuclear plants and for new nuclear plants. There are four current demonstration projects to use heat from operating plants to produce hydrogen, initially for internal use.

He reminded the audience that advanced nuclear is a broad term that encompasses improved light water reactors with passive cooling, and reactors that use different cooling fluids and fuel forms. He told them that reactors will come in a wide variety of sizes including micro reactors <10 MWe, small reactors from 10-300 MWe, and large reactors up to the GW scale and beyond. The size selection enables a broader range of customers and applications.

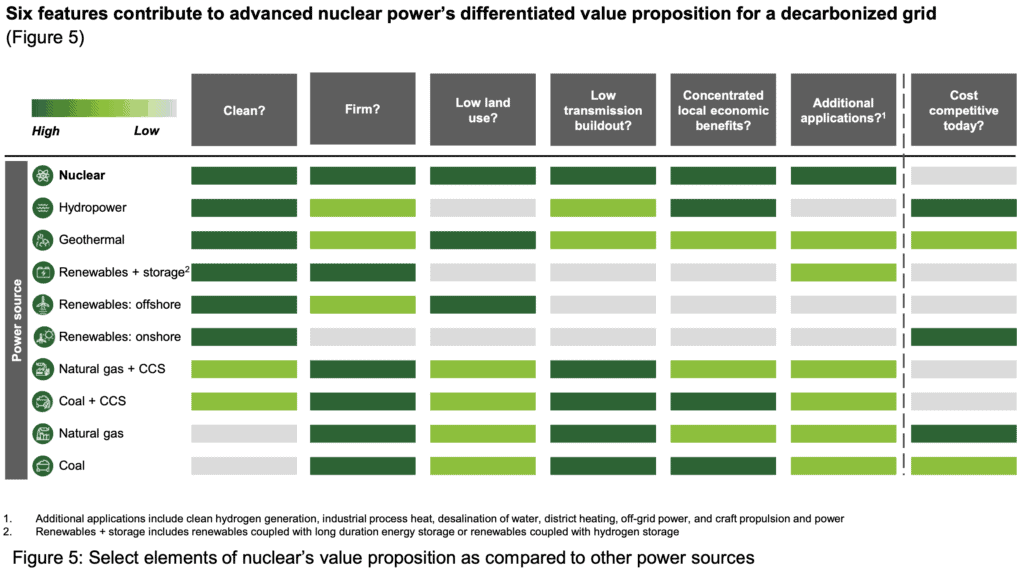

He acknowledged that there is a lot of work to be done and pointed the audience to the recently issued Pathways to Commercial Liftoff report that was led by the Loan Program Office. He showed a table that compared nuclear to nine other energy sources on seven different features. The only one where nuclear fell short was “Cost competitive today?” That’s the area where it needs dramatic improvement, but it is an area that is most clearly under human control.

Then Goff made some statements that noticeably captured audience attention, based on both looking around the room and engaging in a number of conversations after the session. He told us that recent DOE studies show that the US needs 300 GW of total nuclear capacity by 2050. Getting there will require keeping as much of the existing fleet as possible while also building at a rate that exceeds the fastest achieved rate from the 1970s during the period from 2030-2050.

Product and service suppliers care deeply about market growth and the potential for increased sales volume. But the optimism was tempered with caution because the projections don’t indicate a significant order volume before 2030.

The ARDP, funded by the bipartisan Infrastructure Act (the Infrastructure Investment & Jobs Act), was created in response to Congressional direction with a structure that followed their guidance for a three-tiered approach that included two full-scale demonstrations of products that were close to commercial service, five projects designed to retire risks for technologies that showed excellent prospects but needed 5-10 additional years of development before being ready for commercial deployment and two more projects of a more “blue sky” concept development nature. All of the projects were structured for varying levels of public-private partnership funding.

Goff suggested that the audience might have heard something about the two biggest demonstration projects. The Natrium project is a sodium-cooled fast reactor that will be built near a retiring coal plant site in Wyoming. The Xe-100 project is a high-temperature gas-cooled reactor with TRISO-based fuel that will supply heat and electricity to a Dow Chemical production facility in southern Texas.

He informed the audience that the DOE is only funding a portion of the reactors currently under development, but that it is capable of providing technical support and sites for testing and demonstration.

The DOE is striving to strengthen US nuclear fuel production in order to reduce and then eliminate dependence on Russian supplies of uranium and enrichment services. It has received funding under both the Bipartisan Infrastructure Act and the Inflation Reduction Act to stimulate the US industry to establish the necessary capacity. The specific assistance programs are still being fully developed.

Goff acknowledged that the waste issue is still a hurdle that must be addressed. He described how the industry has safely and effectively managed its waste on the sites where it was generated for the past 70 years and said that practice could safely continue for the foreseeable future. But he stated that DOE is making progress towards a more permanent solution. The first step is to site and build a consolidated interim storage facility using a consent-based siting process. In June, a total of $26 M was awarded to 13 different groups as part of the planning and capacity building stage. That’s the first of three steps in the process.

Goff concluded with a description of the All-of-Government approach to international cooperation and project development support. There is general agreement that the US should not cede the international nuclear power plant market to Russia and China. The US wants to be a leader so that it can gain a larger influence on the international norms for safety, security and non-proliferation. He said we have a strong outlook for new nuclear but that the industry needs to deliver on the promise.

Wall Street Perspective

Jim Schaefer, senior managing director of Guggenheim Partners, provided a strong message about the need for nuclear power for meeting decarbonization goals and the pressing need for the industry to improve its ability to deliver projects on time and on budget.

He leads a team of 100 clean energy-focused bankers that have completed 350 deals during the past 8 years. Most of those deals have been in solar, wind and battery storage. He and his team have realized that those technologies are not sufficient for meeting the goal of decarbonizing the grid. Investors and industry need to reallocate dollars towards clean firm technologies that can work all the time.

They have concluded that there is no doubt that hydrogen has a role; geothermal has a role; but that “advanced reactors are kind of it.” He said “Right now, to me, the greatest demand for any kind of energy product that has ever existed is the future need for advanced reactors.”

He sees growing recognition of this insight among investors, in DC, in the electric utility sector, and in the chemical and oil industries. There are hints that the demand signal might begin to appear but that the real demand signal will come after firm orders are being placed.

The current cost and schedule picture of the industry raises real concerns and is inhibiting order placement. Even though there is a growing recognition of the technical merits of nuclear energy, there are good reasons to be wary. Because of recent performance, the financial community has adopted a “show me” posture that is waiting for the completion of demonstration projects that achieve reasonable performance and predictability.

There is no appetite for more projects that put participants at risk of bankruptcy. He pointed to Vogtle 3 & 4, congratulating the team on its impressive achievement of completing the difficult project. He highlighted the fact that Unit 4 showed significant improvements, as the second unit of a kind in the US, and guessed that the 3rd, 4th, 5th, 6th and 7th units would have done even better. But the learning curve was cut off after the second unit, leaving us to wonder what might have been.

Schaefer believes that the US has the best technology in the world and that we have every opportunity to recapture our international industry leadership. He said that capital in our system can move very rapidly if it gets the correct signals. He compared our nuclear enterprise to a football team full of stars that is handicapped by starting its drive on its own 5-yard line with an additional handicap of a 10-foot wall on the 15-yard line.

He expressed appreciation for the leadership being provided by Jeff Lyash of TVA and Ken Hartwick of OPG. Both have stepped forward and indicated a strong appetite for numerous BWRX-300s. He pointed to Dow Chemical as a leader from a new customer base (industrial process heat users) and also talked about the municipal utilities that form the Utah Associated Municipal Power Systems (UAMPS), which plans to build a 462 MWe carbon free power project.

Though he believes that the federal government has provided a lot of support in the form of grants, partnership funding, investment tax credits and production tax credits, he does not think it is enough. He believes that there should be a follow-on ARDP and perhaps other forms of additional funding. He also believes that the industry needs to invest more and begin issuing firm orders.

His optimism is strong but he believes that lack of support and action could result in more of the same slow progress that the industry has been experiencing for a long time. He sees new demand growing, especially with electric vehicles.

He concluded his remarks by stating that “this technology is incredibly important.”

Rod, a wonderfully detailed and very insightful conference summary, which makes me feel like I was there (so now very glad I wasn’t). Thanks for writing and sharing this.

Jim Schaefer’s quote, “Right now, to me, the greatest demand for any kind of energy product that has ever existed is the future need for advanced reactors,” seems to me to be particularly salient and accurate, however awkwardly phrased. Highlights in a subtle way the arbitrage-like investment opportunity for forward-thinking investors who recognize this inevitable future need despite the current market dislocation.

Rod and Valerie,

Yes I agree! Rod, thanks much for a very encouraging and detailed report. I’m also interested in getting more detailed reports on fuel recycling and waste storage which are related important subjects. To be more specific:

Regarding fuel recycling: is there any progress on IFR-style, salt-based, electroplating-based, uranium-and-actinide-separating reprocessing, as in Oklo? My understanding is that the PUREX-style aqueous process was designed to purify Plutonium isotopes, but that the IFR-style process would be useful for separating weakly-radioactive unused Uranium and TRUs from strongly-radioactive fission by-products. This separation, in turn, could be useful for reducing radiotoxic storage lifetime requirements from many millennia to a few centuries. IFR-style reprocessing might also be more useful from a proliferation-reduction perspective.

Regarding waste storage: if used fuel reprocessing results in a waste stream with shorter radiotoxic storage lifetime requirements, would that simplify the search for viable geologic tunnel or deep borehole sites?

It seems that updates from previous Atomic Insights guests could shed light on these subjects.

Thanks again for this week’s update!

@Chris Aoki asks if there is any news on IFR-style molten salt fuel reprocessing, which was to be on-site, in a three-year cycle. If you are thinking of the Molten Chloride Reactors, the reprocessing might be off-site and delayed by many years.

Reprocessing in the IFR was necessitated by accumulated radiation damage to the casings. Without casings or moderator in a MCR, it is the fuel itself that takes the impacts of fast neutrons. Being a liquid, momentum transfers from neutron impacts are instantly healed. We have yet to find out from the MCR Experiment what ages inside a liquid reactor to require a fuel cycle period.

However, in an MCR, fission products would accumulate at a rate of one tonne per year per gigawatt. Much as Rod might say, the most secure place for short-lived fission products is inside a working reactor, so the operators are motivated to keep the reactor going, sealed up, rather than risk spills during a fuel conditioning process. If the breeding ratio is high enough to overwhelm the growing absorption by the FP’s, the reactor might be able to operate for many years. At end of life, its heavily used fuel would mature and cool down slowly inside the decommissioned reactor until its temperature dropped down near the 770° C melting point of KCl. With its burden of plutonium isotopes in fast-reactor equilibrium, the fuel might be deemed valuable enough for earlier reprocessing – off-site.

So another optimistic report. Great!

Let me repeat my somewhat vague questions. How easy would it be to site one of these new reactors? Would they need a small army of Security people? Years ago nuclear plants had to be 40 miles away from major metropolitan areas. Could they actually receive permission to occupy old coal plant sites? I just wonder if the regulations have been revised to be more realistic for the coming era.