Vermont Yankee’s MK I Containment – Upgrades and Mods

One of the results of the accidents at the Fukushima Daiichi nuclear power station has been a legitimate effort to seek answers to the question – “Can it happen here?” Responsible nuclear professionals would not stop there, they would proceed to a series of questions. If so, what should we do right now to reduce the chances of the event? What should we do to reduce the consequences of the event if it manages to happen even if we try to prevent it. (The word you would hear repeatedly during the “what if” conversations is “mitigate” as in “What can we do to mitigate that consequence?”

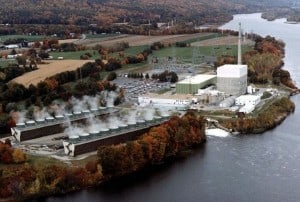

Howard Shaffer is a registered professional nuclear engineer in three states. He has been working for several years as a volunteer to share information about the Vermont Yankee Nuclear power plant with interested people in Vermont and New Hampshire. The below is a brief summary that he put together to explain the differences between the Vermont Yankee nuclear power plant and the similarly designed plants at Fukushima Daiichi.

Vermont Yankee’s MK I Containment

Some critics of nuclear power quote a letter from the ‘80’s saying the MK I had an 80- 90% chance of failure, then leave the statement hanging, as if nothing had been done. A lot has been done.

The GE MK I Containment was designed in the late ‘50’s and ‘60’s based on model tests. Its purpose, the “Design Basis” was to contain and control the effects of a break of the largest pipe connected to the Reactor Vessel. It would also contain the products from a damaged core. The attached cooling systems (Emergency Core Cooling Systems- ECCS) were designed to replace the water lost from the Reactor, cool the Reactor, and cool the Containment. They also provide connections for flooding the Reactor and Containment with river water.

In this original plant design, it was assumed that the grid was lost, so diesel backup was provided. There is 100% backup in cooling and diesels. In addition, there is a direct line to the Vernon dam, bypassing the grid.

The containment was tested when built in place, and is tested by pumping up to design pressure every ten years of so, with compressed air.

In the ‘70’s GE was performing model tests on the MK III Containment. Those tests and some operating experience showed that the MK I Containment needed improvements. The NRC was notified, and required changes. Model tests and advanced calculations resulted in changes in all US MK I plants.

In 1975 the first PRA – Probabilistic Risk Assessment- study was done for Reactor plants. This technology was developed for reactor studies and is a method for “calculating the odds of various accidents happening.” The PRA also studied very rare, but possible, accidents that were not included in the original design of plants – “Beyond Design Basis” – because they were believed to be so rare. The studies proved they are rare events, but with large consequences. The events studied were “blackout” where all a-c power is lost, and Anticipated Transients Without Scram. Further study showed that design measures to deal with these rare events were practical. A “hardened” Containment vent was installed. Periodic venting of the Containment during favorable weather conditions, with an Evacuation having taken place days before, maintains integrity during a core melt event when cooling can’t be restored.

Post TMI, the Containment was inerted with nitrogen to prevent hydrogen explosions in a core damaging accident.

There are strainers in the torus pool to protect the cooling pumps. Their adequacy was questioned and they have been upgraded.

After 9-11, plants were reviewed for the ability to withstand terrorist attack, and prolonged blackout. Changes were made but are classified.

With these modifications, US MK I plants should withstand events causing damage similar to that at the Fukushima Daiichi plants.

Howard Shaffer PE

March 29, 2011

Though Howard did not mention it, I am sure that the Vermont Yankee owners are not complacently resting on what they have already accomplished to modify and strengthen their facility. They are very interested in learning all they can from the post accident investigations and seeing if there is anything else that they should be considering or implementing. The Nuclear Regulatory Commission and the Institute of Nuclear Plant Operators (INPO) have both issued orders requiring a detailed review of systems and procedures in light of the accidents to ensure that no lesson goes unlearned.