PBMR Project Winding Down – Entering Intellectual Property Protection Mode

As long time Atomic Insights readers know, I have been following the developments of the South African Pebble Bed Modular Reactor (PBMR) project for many years – since before the company was formed, in fact. As a result of many factors, the government of South Africa has decided to stop funding the project. Though the details have not been released, the company’s efforts to find customers and additional investors have also failed, so the project team is being reduced from about 800 scientists, engineers and technicians to an interim head count of about 25 people.

As far as I can tell, none of the remaining members have “update the web site” as a task that is high on their priority list. The most recent press release posted is from March 8, 2010, announcing the resignation of Jaco Kriek from the position of CEO.

There was an article published on July 15, 2010 on timeslive.co.za titled Government pulls plug on PBMR that provides some additional information about the current status of the company, some key expenditures since project inception in 1999 that added up to 9 billion rand ($1.19 B), and the remaining assets.

The Pebble Bed Modular Reactor Company (PBMR), which was established in 1999 to build small nuclear power reactors, faces imminent closure.

In a letter dated July 5, Public Enterprises Minister Barbara Hogan told the National Union of Mineworkers (NUM): “The minister of finance has clearly stated that there will be no further funding for the company, and I would like to reiterate that this position has not changed.

“It is clear that the remainder of the cash on hand is to be utilised solely for the winding down of the company as well as the preservation of the intellectual property.”

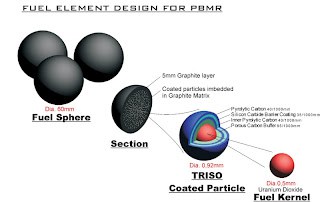

Though there are many factors that led to the demise of this project, it is important to understand that the failure does not mean that pebble bed reactors using high temperature fuel made up of particles coated with several protective layers is an inherently bad idea. It most certainly does not mean that smaller reactors or reactors targeted for the process heat market are doomed to failure.

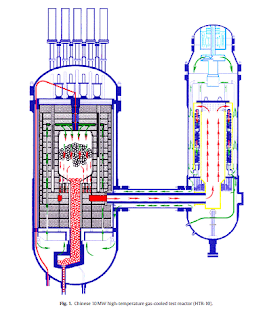

There is a 10 MWth research and test reactor operating in China today called the HTR-10 that is performing well enough in testing to encourage the construction of at least two additional larger units in Shidaowan, near Rongcheng in Weihai city. This commercial demonstration station will consist of two 250 MWth HTR-PM modules feeding a single 210 MWe steam turbine.

In contrast to the technical choices made at the beginning of the PBMR project to design and build both a pebble bed reactor heat source AND a unique, helium cooled direct cycle compressor-turbine unit “balance of plant”, the Chinese engineers decided to refine a physically proven system using helium circulated and heated by a graphite moderated nuclear reactor to produce steam for a conventional steam plant. That combination produced significant quantities of power in the past at the 330 MWe Ft. St. Vrain nuclear power station in Colorado and at the 300 MWe Thorium High Temperature Reactor (THTR) in Germany. Though neither one of those examples had operated for a full commercial lifetime, both were far more than “paper reactors” or test platforms.

The combination that the PBMR engineers chose had never before been constructed; in fact, the 165 MWe helium turbomachine envisioned for the project existed only on paper. Unfortunately, it took the project leaders many years to recognize the technical difficulty and cost challenge of designing and building a unique turbomachine using helium from scratch. After about ten years of various design changes and contractor shifts, the project leaders decided last year to abandon the direct cycle gas turbine part of the project and focus on using the pebble bed reactor as the heat source for industrial processes.

That decision apparently came at the wrong time to save the project. (Either it was too late and the funding decision makers within the South African government had lost patience, or it was not well received by potential process heat customers because they have other choices available that are cheap enough.) Probably because of the uncertain status of their PBMR partners, I recently learned that Westinghouse has declined to participate in the US NGNP detailed concept design, even though they were initially chosen to receive half of a $40 million DOE project award. At this point, the remaining option for NGNP is the prismatic core design that General Atomics prefers.

I hope, for the sake of the South African taxpayers, that the people left at PBMR Co. Pty. do a good job of obtaining some value for the intellectual property that they developed. There was a time when many people around the world were looking to South Africa to produce the first of a kind high temperature gas cooled direct cycle nuclear power plant, and the team took some important steps. From a very long distance away from the project, it appears now that the steps were not well considered or focused on moving in a fertile technical direction. There are some lessons to be learned here about the value of evolutionary vice revolutionary design and the importance of getting products to market before funders lose patience.

For the record, I am still fascinated and enthusiastic about the potential applications of what an old friend and mentor used to call my “hot rocks” concept of reactors that are formed by filling a “bucket” full of a suitable number of balls containing a mixture of graphite moderator, heavy metal fuels, and adherent coatings that prevent fission product releases. Someday, I hope to have the opportunity and the resources needed to show the flexibility of this fuel/reactor concept using nitrogen, an inert gas that works well in conventional combustion turbomachinery.

Rod, you might be interested in attending the “Fluoride Salt-Cooled High-Temperature Reactor

Workshop at ORNL on September 20-21. https://www.ornl.gov/fhr/

This workshop will focus on proposals to combine Molten Salt and Pebble Bed technologies. The big advantagea are that it yields a much more compact core, and both technologies are well developed. The major advantages include a much more compact core, and thus materials costs would be significantly less, plus molten salt would be easy to work with as an industrial heat source.

Thanks for the tip, Charles. I have registered for the workshop. Is this the technology that Per Peterson has been working on?

Rod,

I believe you are a bit oprimistic on the success of the Chinese HTR10: There are no official reports about operation but inofficial information talk about 2 weeks operation time in 2008. There seem to be huge problems with pebble flow in HTR-10: If you look in the official AVR (German PBMR) list of problems you will find a lot of reference to oebble circulation, too.

Rainier

@Ranier – Thank you for the information. Do you have any sources that you can point me to. As you said, there is a dearth of information on the web about the current operations. I have some video of an Australian Broadcasting Corporation Catalyst program that visited the site, and several friends of mine have also been there, but not in the past couple of years.

At the time of the information that I have things were functioning well, but I would not be surprised if there were some technical issues to overcome. It is, after all, a test bed and when you are working with real equipment there are occasionally engineering challenges to address and failed equipment to fix.

I will say that I have never been a fan of the continuous fueling concept. There are ways to make the bed of pebbles fixed and to use rotating drums and control rods inserted through guide tubes to control reactivity and account for fuel depletion over time.

Rod Adams

I’ve focused on the turbine problem. This is a major area of R&D that has, according the PBMR Westhinghouse rep on Rod’s podcast a year or so ago, noted was the biggest stumbling, and therfore, money block, to the full range, gas cooled, gas driven, PBMR-Brayton Turbine reactor set.

*Everyone* who follows Gen IV reactor developments needs to take note, as Rod has, of this problem. The *closed* cycle Brayton turbine is a new species, a mutated version of the open cycle gas turbine we use to power CCGTs, SCGTs and ever jet plane that flies. Of any “$5 billion” to develop, for example, a LFTR, we will have to devote at least $1.5 billion or more to developing a working closed cycle Brayton turbine. I think the real costs will be closer to $10 billion. Certainly worth it from a host of levels we can discuss. But it’s a real issue.

David

Rod, The concept is shared by Per Peterson and ORNL. it uses the Molten Salt technology developed by ORNL during the 1950’s, 60’s and 70’s in its various MSR projects. I am sure that Kirk will show up for this workshop. if you come, we could have a nuclear blogger’s convention in a Knoxville dive.

I think South Africa has also faced international opposition from the US Govt on it’s PBMR plan. It violates the whole “GNEP” concept that “countries that don’t currently have fuel cycle facilities shouldn’t be building fuel cycle facilities.” An important aspect of PBMR for South Africa is that South Africa wouldn’t just be mining U ore, but would be enriching U, fabricating fuel elements, and shipping the rest of the reactor technology — getting much more value out of its natural resources than it would otherwise.

@paul_houle – please say it ain’t so. You mean that the “pro-nuclear” Bush Administration was actually fighting such an interesting nuclear development as the PBMR? I’m shocked, shocked I say.

“I think South Africa has also faced international opposition from the US Govt on it’s PBMR plan.”

Oh, I seriously doubt that. PBMR has been in a financial tight spot for about a decade, and as I recall, South Africa didn’t publicly speculate on reviving its uranium enrichment capability until 2007. By that time, there was little significant that the US could do to influence the fate of this company one way or another through pressure alone. Nothing short of a bailout would have had much effect.

Certainly, the Bush administration, which only had another year in office by 2007, would not have exerted any pressure because of GNEP, since GNEP was pretty much already the walking dead a year after being announced in early 2006. Much of the funding proposed for GNEP ended up in NGNP, and as the article here mentions, PBMR’s design was seriously considered as the concept for the NGNP until Westinghouse recently pulled the pebble-bed design from consideration.

Dear Rod

There is recent news of a Thorium MSR reactor going into production soon see http://www.itheo.org/articles/itheo-presents-ithems

In the article it says they just need 333 Million $US to get started. For Nuclear that seems small. Any idea or feelings about the probability of such a venture? I know that if the US nuclear renaissance is to get a kickstart

that a US investment here would make sense.

David Walters says, “The *closed* cycle Brayton turbine is a new species, a mutated version of the open cycle gas turbine we use to power CCGTs, SCGTs and ever jet plane that flies. Of any “$5 billion” to develop, for example, a LFTR, we will have to devote at least $1.5 billion or more to developing a working closed cycle Brayton turbine.”

Brayton turbines are closed-cycle by definition. They exist at small scales. According to the Times article — the Johannesburg Times? South Africa Times? — 503.2 million rand was in fact paid to Japan’s Mitsubishi Heavy Industries for a helium turbine.

(How fire can be domesticated)

David means closed system versus open system.

@G.R.L – yes, Mitsubishi and Westinghouse have been paid several tens of millions of dollars for work associated with producing a helium turbine, but there is no turbine. I would not expect there to be any turbine for that amount of money; when GE, Rolls Royce, or Pratt & Whitney refine an existing combustion turbine design to produce a new model, they often spend several billion dollars before the first production units are fully manufactured and tested.

It is not the closed cycle part that is a challenge – what is a challenge is the nature of the working fluid. Not only have closed cycle gas turbine concepts normally envisioned using helium, but they envision using helium at very high pressures – perhaps 1000 PSI in the high pressure part of the system and more than 400 PSI in the low pressure part.

The combustion turbines that have performed so well to addict electric utilities on natural gas or the ones that power aircraft operate with the low pressure section at atmospheric pressure and the high pressure section at perhaps 15-25 atmospheres (less than 400 PSI).

If you choose a gas that is just like air (a mixture of N2 and O2) and keep the pressures and pressure ratios close to those that exist in proven open cycle machines, you can readily adapt existing machinery to closed cycle use. If you try for a different working fluid condition for other reasons, you buy into an expensive gas turbine design and manufacturing challenge. Mind you, it is not “impossible” but it might just be enough to kill any economic advantage that you might obtain from trying to simplify the system in comparison to a light water reactor-steam plant combination.

http://adamsengines.blogspot.com/2009/09/nitrogen-n2-gas-cooling-for-closed.html

So, GA is the winner of the NGNP competition by default, then?

Last I heard, the NGNP project has not made the decision on whether it will proceed to the next phase. There might be no “winners,” except those companies who have pulled in some keen taxpayer-funded revenue to produce studies on designs that they never actually, realistically expected or intended to build.

Those companies shall remain nameless, of course.

In short, you might be right, but not for the reasons you think.

Ouch. That would be the worst possible outcome.

Didn’t AREVA get “voted off the island” – so to speak (for reasons unknown – or at least unclear)? Perhaps they could be asked to get back on board?

HTGRs are useful reactors. It would really suck if the plant was cancelled and everything was ceded to the Chinese.

I had another idea. If it’s infeasible to proceed with GA and their partners du jour, and AREVA isn’t interested, then let a contract to B&W to develop a supercritical water reactor as the NGNP. B&W actually has built a lot of plants, knows what they’re doing, and their core competence is steam. The SWR is evolutionary, with revolutionary aspects (materials, I hear.)

“B&W actually has built a lot of plants, knows what they’re doing, and their core competence is steam.”

The problem with that idea is that the company that built all of those old B&W plants now is AREVA.

What is called Babcock & Wilcox today is just the Navy Nuclear section of the old Babcock & Wilcox company. The French bought up the commercial side of the business beginning in the late eighties.

The expertise of B&W (formerly known as BWXT) is naval reactors and the fuel for those reactors. Thus, it’s not surprising that they took what used to be a design for a maritime reactor and decided to turn it into a small, modular power reactor, which is what the mPower design is.

Brian – I am not sure what your point is here. Are you saying that naval power plants are anything more than just shock mounted, responsive steam plants with specially designed long lived cores?

Yes, part of the commercial side was sold to Framatome (now Areva), but the portion that is now B&W retained an extensive capability and expertise in steam and steam plant components. They also have retained a significant level of expertise in fuel manufacturing, producing not only naval fuel but also research reactor fuel, including converting many research reactors from HEU to LEU. They have also been the fuel manufacturer that has supplied the test pellets for the NGNP testing program.

As Chris Mowry told me during the press conference announcing Generation mPower, the decision on who will supply the fuel for the mPower has not yet been made.

“Brian – I am not sure what your point is here.”

Dave commented that “B&W … has built a lot of plants.” I just wanted to let everyone know that it wasn’t that B&W that designed and built those plants.

In any case, steam and supercritical water are two very different fluids. Knowledge of steam is not going to help much in designing and developing a supercritical water reactor. Experience with supercritical fossil-fuel-fired boilers would be much more useful.

@Brian – you may be correct, but B&W’s product listing on their web site includes supercritical coal fired boilers.

http://www.babcock.com/products/boilers/

That is not a web page created before a portion of B&W’s commercial operations were sold to Framatome – in the early to mid 1990s. It is a current web page.

Here is a link to a document with a pretty decent description of B&W’s manufacturing capabilities in their Canadian subsidiary.

http://www.babcock.com/bwc/manufacturing/docs/mfgcapabilities.pdf

And here is one more link to a description of their supercritical boilers offerings:

http://www.babcock.com/products/boilers/supercritical.html

“B&W’s product listing on their web site includes supercritical coal fired boilers.”

Not surprising, because B&W made a name for itself in the boiler business long before fission was even a concept.

Yup, as the introducers of the water-tube boiler, B&W made a quite a name for themselves. Probably the single biggest advance in boiler technology since the introduction of the safety valve for pressure vessels by persons unknown.

Just as the safety valve (crude versions being used by 17th century proto-chemists) turned operation of pressure vessels from a near suicidal activity to a thrilling, suspenseful, and dangerous activity, the water tube boiler turned boiler operation from a thrilling, suspenseful, and dangerous activity into a somewhat routine, relatively safe affair. If something went wrong in a B&W boiler, it would likely go wrong in a single water tube, and the boiler would forcibly blow down into the combustion chamber, killing the fire, rather than a seam rupturing on a large-volume tank and the boiler taking off like a rocket or exploding like a grenade, causing massive loss to property, likely deaths, and certainly injuries. B&W gave industry boilers that were very safe provided maintenance schedules were followed, whose critical, fire-exposed surfaces were completely descalable and replaceable – without having to enter the boiler itself (manual descaling taking on an extraordinarily importance in the days prior to chemistry control; entering the boiler even when it was off in a multi-boiler plant was not very safe; there were no OSHA lockout-tagout regulations in those days) and were designed soundly and efficiently.

The water-tube boiler allowed steam to power the reciprocating prime movers of the first electrical light plants reliably at a relatively low cost, and eventually, with the introduction of the alternating current and the Parsons turbine, the modern central station.

INL is also working on a graphite-core reactor–Triso particles.

http://www.inl.gov/technicalpublications/Documents/4074980.pdf

The new South African government, like the Obama Administration, has no understanding of physical economy,

specifically the concept of a science driver to increase the nation’s productivity and future prosperity. Investment in the Apollo Program, for example, was a science driver, putting back into the economy at least $10 for every dollar spent. Investment in next-generation science and technology is not “cheap,” but it’s essential as the only way to assure that an economy will flourish in the future. The de-funding of the PBMR (and the proposed de-funding of a Moon-Mars program and lack of nuclear investment here), is a sure way to a new dark age. Likewise, throwing billions into useless so-called “green” technologies will only serve to keep Africa in the dark, and speed the collapse of the U.S. economy.

For more on the transformative power of advanced technologies–like nuclear–for the entire

economy, see “The Astounding High Cost of `Free’ Energy”

http://www.21stcenturysciencetech.com/Articles%202008/Energy_cost.pdf