Nuclear Infrastructure Council and Argonne teaming up for a trailblazing nuclear tech summit

Interest in alternative nuclear energy technologies continues to strengthen, despite the challenging financial environment and despite the regulatory hurdles that need to be moved out of the way. Atomic energy innovators continue to be inspired by the technical promise of highly concentrated fuel, tiny waste stream and zero air pollution or CO2 production. The potential suppliers to the industry remain interested in the potential for significant new markets for their high quality products.

On February 8 and 9, the growing community of nuclear technology trailblazers return to Argonne National Laboratory, the site of the first in the series of Advanced Reactor Technology Summits, for the fourth annual event. The event is being organized under the auspices of the Nuclear Infrastructure Council in conjunction with the Argonne National Laboratory. Atomic Insights will be there to cover the talks, ask hard questions and get the inside scoop whenever possible.

Event co-sponsors include General Atomics and Terrestrial Energy. Trailblazing sponsors include Muons Inc. NuScale Power and Studsvik. X-Energy is a contributing sponsor.

The confirmed speaker line up is an impressive roster of company leaders, thoughtful analysts, financial backers and government sponsors. This year’s event includes both sponsorship opportunities and a new technology showcase designed to give suppliers a unique opportunity to present their products and services to “a captive audience of 200 key industry and government leaders.”

Registration for the event is open now. The attendance fee will increase by $200 on January 20. That’s probably designed to help people make an prompt decision to attend.

The agenda is still under development, but here is the current outline of topics to be covered.

Advance Agenda Topics

Keynotes:

- U.S. Department of Energy

- U.S. Nuclear Regulatory Commission

- Nuclear Energy Industry

- National Laboratories

- Reports From Leading Advanced Reactor Technology Developers

- Progress On Overarching Issues: Capital Costs, O&M, Fuel Cycle Strategies, Licensing Timeframes, Demonstration And Deployment

- Test Reactor, Prototypes And Demonstration Concepts

- Government / Private Sector Collaboration & Leading First Movers

- DOE, National Laboratory And Private-Sector Incubators, Including The Gateway for Accelerated Innovation in Nuclear (GAIN)

- The Economic & Environmental Nexus For Advanced Reactors

- The New Administration And Congressional Landscape

- U.S. And International Markets

- Moving Forward

It’s worthwhile to read Third Way’s reports on the advanced nuclear energy industry as preparation for the event. There is no real substitute for making face to face contact with other members of the advanced reactor community if you have a strong interest in keeping up with the technology, want to participate in new developments or want to determine if the technology is ripe for your investment dollars.

See you there?

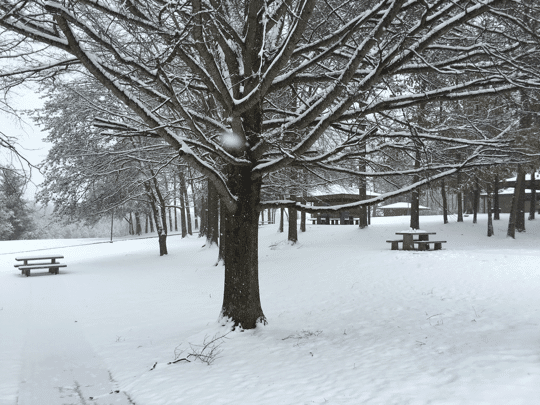

PS – Yes, I know that ANL is in the heart of the snow belt and perhaps a risky place to hold a meeting in February. Last year, the Advanced Reactor Summit organizers held their event at ORNL in Oak Ridge, TN. Perhaps they hoped to reduce the potential for disruption caused by the snowfall experienced in Amherst, MA during the second annual event.

It didn’t work. Here is a photo I took on my drive from Lynchburg to the 2016 summit.

I’ve been following this site (and other nuclear innovation related sites) for quite some time.

Many good ideas are presented in the realm of technology, but one idea (somewhat outside of technology) has been very well presented on this site: the inherent superiority of small plants over large ones.

While large ones can benefit from “economy of scale” per UNIT, the economy of scale inherent in a “production run” is also valuable.

Moreover, smaller plants can feasibly have a prototype.

Anyway, I am glad to see that that aspect of nuclear energy development is on the agenda.

@Rick Armknecht

Your insight and comments are Spot-On. If indeed the size of some of the GEN IV Nuclear Reactors can be small enough to be modularly built in a factory setting it could indeed contribute to higher quality and lower cost.

Having been involved in electronic and electro-mechanical manufacturing for the automobile industry beginning in the late 70’s I participated in the catharsis of the American automotive industry as the Japanese and Germans produced higher quality, more fuel efficient and in many cases lower cost cars. The need for change was evident.

Enter W. Edwards Demming and Joseph Juran and the adoption of Statistical Process Control (SPC) to American automotive manufacturing. Demming had successfully introduced the principles, practices and techniques of SPC, initially developed by physicist, engineer and statistician Walter Andrew Shewhart, to Japan with great success resulting in the Demming Award being the highest accolade for Quality Manufacturing in Japan.

The use of Pareto Analysis, Failure Modes and Effects Analysis (FMEA), Significant Characteristics Analysis to name only a few of the techniques of SPC, lead to a renaissance in American automotive. Tremendous quality improvements and cost containment resulted in products that were world class and competitive. There were, of course, structural financial burdens such as UAW contracts and legacy costs which were not addressed for some years, but that’s outside the realm of SPC.

Being small, standardized and modularly built in a factory setting is NO GUARANTEE that quality would be improved or costs reduced but it provides an environment in which SPC can thrive and thus provide those guarantees. Let’s hope the physicists, engineers and managers in Nuclear heed the lessons taught to Automotive by Demming and Shewhart.

Interesting piece when it comes to energy and emissions:

How fertiliser helped feed the world

“the Haber-Bosch process today consumes more than 1% of all the world’s energy. ”

( http://www.bbc.com/news/business-38305504 )

Fritz Haber was a genius who gave the world bread from the air.

His life also presents a very poignant study in the ethical use of science and concomitant personal tragedy.

Its stunning. A weird, wonderful and tragic mix – on several layers and from multiple perspectives.

“When the Nazis took power in the 1930s, however, none of this outweighed his Jewish roots.

Stripped of his job and kicked out of the country, Haber died, in a Swiss hotel, a broken man. ”

I’ve been told many times that it ain’t whatcha know, it’s who ya know. This is another extreme example.

Back to the main article. Are the massive requirements that now apply to the huge nuclear plants going to apply to these proposed smaller plants? Will they have to spend the 5 million dollars that was noted in a previous Atomic Insights post? Could they be largely be remote controlled with roving maintenance and operation crews that could handle multiple sites?

Note: 5 million for security only.

My understanding is the costs are being evaluated for scaling down, based upon the inherent design features for many of these new types of Rx. Clearly, the same level of security should not be required if the plants are designed appropriately to incorporate the safety/security interface (Rx modules underground, passive safety features, fuel types, etc.). If we haven’t learned to require some realism from this go-around with the current LWR/BWR generation, we have no one to blame but ourselves if these advanced concepts don’t succeed.