Diamond batteries would turn C-14 into a valuable byproduct of Adams Engines

Researchers at the University of Bristol have excited geeks around the world by announcing they had successfully demonstrated artificial diamonds that produce an electrical current when exposed to radiation. Their research has been inspired by a fact that is almost unique to the UK. There is a large stockpile of radioactive carbon-14 available as a result of operating a number of graphite-moderated, gas cooled reactors starting in 1956 and continuing today.

When faced with a large inventory of potentially hazardous material that no one seems to want, people have two primary choices. They can fret about ways to store or dispose of the waste or they can find ways to extract value from the material.

The University of Bristol researchers have produced a short video to explain how they have chosen the second path and to describe the destinations to which it might lead.

The development has the potential to address an issue has been one of many obstacles to building Adams Engines. I’ve been wondering how to convince others to accept C-14 as a potentially useful byproduct that needs to be handled instead of thinking of it as an insurmountable barrier.

What is an Adams Engine?

Adams Engines have been under conceptual development since 1991. The fundamental idea is to use proven nuclear fuel capable of heating a flow of moderate pressure gas to ~ 800 ℃ or higher. That flow of gas would be piped directly to a simple cycle gas turbine to produce electricity. A variant would eliminate the power turbine and instead produce a hot stream of gas useful for process heat applications.

This path breaks from precedent but seems to be a path toward a radically simplified power system using atomic fission as a heat source.

High temperature reactors

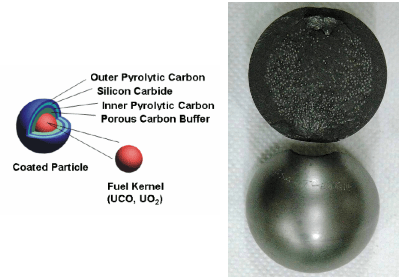

High temperature gas cooled reactors have been under development since the late 1940s. Several, including Dragon, AVR, THTR, Peach Bottom 1, Ft. St. Vrain and HTR-10 have operated with varying degrees of success. Technolgists in the field have almost universally decided to use a tristructural isotropic (TRISO) coated particle fuel that contains fission products even when raised to temperatures in excess of 1600 C.

Almost everyone in the field of high temperature gas reactors selects high pressure helium as the heat transfer medium to move thermal power out of the reactor.

Using helium locks out the direct use of commercially available compressors and turbines. That doesn’t seem like a very big obstacle, but developing turbo machinery that is well suited for high pressure helium has proven to be challenging enough to kill several promising development projects.

A few designers have considered using a helium to air heat exchanger and a piping loop with a helium circulator to enable the use of conventional, air breathing turbomachinery, but that idea locks in a higher number of components. The heat exchanger, which is easy to insert in a drawing, has material and manufacturing challenges that will fundamentally change the system cost structure.

The Adams Engines concept avoids the challenges imposed by helium and instead uses nitrogen as the reactor coolant. The same hot nitrogen that transfers heat from the reactor serves as the working fluid in the turbo machinery that converts fission-originating heat into motion. Using nitrogen at appropriate temperatures, pressures and flow rates gives Adams Engine designers access to a wide range of proven machinery that has been designed and manufactured for the combustion turbine industry.

Why does everyone else use helium?

From a reactor engineer perspective, helium is an almost ideal coolant. Though its ability to move heat is limited by its low natural density, helium has a high specific heat transfer coefficient per unit mass. That gives it a reasonable volumetric heat remove capacity, especially if the system is operated at 50 – 100 times atmospheric pressure. It’s inert, eliminating corrosion inside pipes and tanks as a concern.

Its real beauty as a nuclear reactor coolant is that it doesn’t absorb neutrons. Helium doesn’t affect reactor core reactivity and it doesn’t become radioactive.

From a heat transfer engineer’s perspective, there are other gases that can move heat from a reactor just as well. Two of those available gases, atmospheric air and nitrogen, are useful in commercially available gas turbine machinery because they have the gas properties (density, specific heat transfer coefficient, etc) for which those machines are designed.

Atmospheric air has three drawbacks.

- Air contains oxygen that has the possibility of reacting with materials in the reactor and in the piping systems when at system operating temperature.

- Air contains a small amount of Ar-40, which gets activated to Ar-41 when exposed to a neutron flux. That isotope decays with a penetrating gamma emission that can cause exposure hazards. It is a short lived isotope with a 1.8 hour half life, so it is not a long term pollutant.

- Air contains nitrogen.

Using just the nitrogen component of atmospheric air eliminates the first two issues. Challenges associated with the third issue are increased a bit due to the marginally higher concentration of N2.

The main reason that almost all other high temperature gas reactor projects have chosen helium over nitrogen is that N-14, the most abundant natural isotope of nitrogen, has a moderate cross-section for neutron absorption. It undergoes a neutron absorption/proton emission reaction that produces C-14 and hydrogen. Hydrogen is stable and not a challenge to eliminate in the tiny quantities that it is produced.

Neutron absorption has a small effect on core reactivity, but that issue can be mitigated.

The issue that other designers have chosen to avoid is that C-14 is mildly radioactive. It decays with a 5,730 year half life by emitting a single low energy beta particle that turns it back into N-14. C-14 isn’t a general area radiation issue because its weak beta is readily shielded and will only travel a few centimeters even in dry air. There are concerns, however, that C-14 may cause health problems if enough of it is ingested to give the host a dose large enough to cause harm.

If the University of Bristol researchers successfully create battery products that use C-14 as a raw material, a former barrier could turn into a potential revenue opportunity. That’s an outcome that would stimulate a small celebration.

A lot of cool stuff can be made out of a low-energy beta emitter if it is available in macroscopic quantities. But the cost of extraction (=decontamination) of C-14 from irradiated graphite is prohibitive.

The U of Bristol announcement is misleading.

The authors opted for a cute video instead of providing some facts & perspective.

At about 1.3 tonnes of synthetic diamonds per Watt of electricity, who in their right mind would ever consider actually building such a ridiculous battery ?

Some calculations:

A Russian report gives approximately 8% energy conversion efficiency.

http://www.naun.org/main/NAUN/circuitssystemssignal/2015/b182005-012.pdf

Average Carbon-14 decay energy is 50keV (1eV = 1.6E-19 joules).

Multiplying by 6.02E+23 and dividing by 14 gives 344MJ/g total decay energy.

Half of that energy, 172MJ/g, is released in a 5730-year half-life, so the power per gram is 172E+6 J / (5730 x 365 x 24 x 60 x 60 seconds) = 0.95 mW/g

With an 8% energy conversion efficiency, that comes to about 0.076 mW/g of pure C14.

If the graphite from decommissioned nuclear reactors contains 1% C14, then without isotopic separation, the expected electric output of the synthetic diamonds would be 0.00076 mW per gram.

Or about 1.3 tonnes of synthetic diamonds per Watt of electricity.

How much energy does it take to produce a tonne of synthetic diamonds ?

——————————-

PS. I’m still trying to get at the C14 concentration in graphite moderator blocks.

Pure C14 has a specific activity of 4.5 Ci/g or 0.167 TBq/g or 167,000 TBq/tonne.

If we take the Magnox graphite C14 production figure of 10.8 TBq/GWe-y and combine that with typical operating parameters (about 6.9 GWe-y lifetime) we get:

10.8 TBq/GWe-y x 6.9 GWe-y = 74 TBq of C14 total per Magnox reactor.

With an inventory of 3,500 tons of graphite (3,175 metric tonnes), that comes to an average C14 activity of about 0.025 TBq/tonne of moderator.

Therefore the average C14 concentration is:

0.025 TBq/tonne of moderator ÷ 167,000 TBq/tonne pure C14 = 1.5E-7 or 0.000015%

That’s extremely low !

Ten thousand times less than just assuming that all C13 (1.1%) gets converted to C14.

Did I make a mistake somewhere in the algebra ?

@Jaro

Your math may be correct; I haven’t had the chance to work through it yet. But what if there was a source of reasonably pure C-14 available?

I thought the video indicated that a radiation field was required to operate the battery, implying that the electric power produced was not due to C-14 decay alone. Could this be a kind of photovoltaic cell that uses radiation produced by a reactor rather than sunlight? Could be very useful for direct conversion in a nuclear fusion reactor.

The C-14 decay creates the radiation field internally.

@ Jaro

The video is also wrong where (at about 1:35) it says that “carbon-14 will eventually turn back into regular carbon.”

Um — NO.

As Rod CORRECTLY says: “C-14 is mildly radioactive. It decays with a 5,730 year half life by emitting a single low energy beta particle that turns it back into N-14.”

Indeed, and this may be another fly in the ointment, as the constant creation of nitrogen changes the semicondicting properties over time. N is a deep donor in diamond. In a pure C14 diamond the N concentration would increase by 120 ppm per year, and in semiconductor physics, each ppm matters a lot.

You’re averaging over 5730 years of life. The initial power output, and the output over the useful life of anything it powered, would be somewhat higher:

344 MJ/g * ln(2) / (5730 *365.25 * 86400) = 1.32 mW/g

At 8% conversion efficiency this comes to about 105μW/g electric output.

That’s plenty of power for a great many kinds of sensors and other things that you might want to plant e.g. on the sea floor or in a glacier and leave for a period of decades. Storing energy in capacitors could supply bursts of power for data transmission.

I’m assuming that we’re good enough at isotope separation that we could generate 90% or so pure C-14 if we really wanted to.

Cryogenic distillation of CO is used for carbon-13, it would work for carbon-14

Jaro, I agree with your calculation, with EPs correction. 20 μW electrical output per carat of synthetic pure C14 diamonds. I am dismayed enough by innumerate hopes into the latest battery breakthrough by renewables enthusiasts, but this really tops it as far as ridiculous battery proposals go.

Sounds expensive, but if beta-voltaic diamonds are a viable alternative to Pu-238 RTGs I’m all for them.

I have to admit, the use of diamond diodes excited by their own internal beta radiation instead of externally applied photons is a stroke of genius.

Oh, the irony. Potential battery evolution touted as a boon to the nuclear industry.

Never mind that battery evolution, energy storage, has consistently been criticized here as pie in the sky, in order to tout NE as the only real answer to our future energy needs.

Envisioning a future where radiation makes large scale storage of energy (produced by renewables) possible, has a sweet irony that cannot be ignored.

I was a bit skeptical that this could work as advertised at first. Id like to learn more about the process. Its solely beta decay that enables this?

Interesting, but I believe that the Adams Engine would be better with nitrogen-15.

I know, I know — that would require an entirely new industry to obtain the needed amount on nitrogen-15. Still, half of that industry may already be in place and operational:

What if the air liquefaction plants currently in operation were to add an N2 distillation (or diffusion or centrifuge) step to their plants?

Centrifuge enrichment of ammonia.

OK — there certainly is an existing NH3 industry for the feedstock.

Also, that method could provide the basis for some D2O production.

Poa, a certain amount of irony but not a lot. No one is suggeting *mass* battery storage this way. It’s not even akin to a “nuclear battery” which is not a battery at all but simply a reactor with, say, 30 years of fuel in it, as all the US Navy’s new reactors operator. *Effectively* a battery but not really. Not rechargeable anyway.

I look forward to real utility scale storage “batteries” though they will always be too expensive to seriously deploy beyond “first of a kind” (and last of a kind) experiments or remote areas. Why? Because *any* successful storage will *always* work better with nuclear than with renewables. This is why Helms Pump Storage, at 1200MWs, was built: to work with Diablo Canyon Nuclear Power Plant.

Energy storage can be gravitational (a dam), electrical (battery or capacitor), mechanical (flywheel, compressed gas), thermal (molten salt), chemical (fossil fuel) and nuclear (reactor core). With one exception, each becomes more dangerous with greater energy storage density (assuming increasing densification can even be achieved).

The exception is nuclear.

” *any* successful storage will *always* work better with nuclear than with renewables.”

That sounds plausible, but can you link to a solid argument for this?

In order to store energy, it must first be produced. Renewables often have trouble with the producing part.

I just read an interesting article about a new design wind turbine that can withstand and produce power in sustained gail force winds.

To hear many of you tell it, renewables have reached their apex of development.

When I was a teen, I built a hot rod ’31 Model A pick-up. Put a flathead 8 in it. My last build was a ’67 chevy one ton flatbed. Put a fuel injected 396 in that one. Good thing you guys weren’t designing our early cars, or we all would still be driving those Model A’s, there wouldn’t have been a flathead to stick in one, and a fuel injected 396 would be science fiction.

@poa

There are certainly improvements that can be made in wind turbines.

Is this the article that you recently read? http://www.smithsonianmag.com/innovation/can-we-capture-energy-hurricane-180960750/

No, Rod. Heres the article…

http://inhabitat.com/innovative-new-wind-turbine-from-iceland-is-tough-enough-for-the-strongest-gales/

Now if only we could create gale force winds on demand.

In Iceland, you don’t need to demand them. Kinda shoots down the intermittancy argument, don’t it?

yea, because we all really want to move to Iceland to enjoy somewhat less intermittent gale force winds

Chuckling, John. Thanks, kinda refreshing.

But, uh….if ya lived there….remotely….which would be more sensible to put on your Christmas list….a nuclear reactor…or a wind turbine?

Hmmmm….eenie meanie miney mo…..

A nuclear battery may be the most realistic, versatile, reliable and desirable for individual needs in the not too far future.

Yeah, Tucker. But today, we gotta live in the real world.

And no one buys a windmill when they need a gas generator.

Apparently, in parts of Iceland, you don’t need a gas generator if ya got a wind turbine.

Buy gas….or listen to the wind spin your lights on….

Eenie, meanie…miney moe….

Hydro is what really helps out Iceland. Geothermal too. Those have much better capacity factors than wind.

With 75% hydro and 25% geothermal, Iceland can also integrate some wind and build more Al smelters. Not every country is that lucky.

Fow gas cooled reactors to make sense economically they have to be a direct cycle. otherwise the savings made on simpler decay heat rejection using radiation is offset in larger reactors and larger heat exchangers to pass the heat on to another working fluid.

If a direct cycle is used than an expensive and large heat exchanger/steam generator is removed (these are often as large or larger than the reactor). the savings therefore make it potentially significantly cheaper than a LWR.

I agree with Rod if you are to achieve this it is hard enough designing a new reactor never mind designing a whole new turbo machinery. thus a new reactor operating on direct helium cycle is unlikely ever to get off the ground due to cost associated with two high risk development streams (this is shown by the south African attempt which failed due to difficulty in delivering both the turbo machinery and reactor).

The two approaches are therefore build a helium cooled reactor with heat exchanger to power conventional turbomachinery. once that is an established technology then at a later date design the helium turbo machinery for evolution two of the reactor. other option change the coolant to nitrogen and use existing turbo machinery and bear the risk of developing control methods for C14 production which are acceptable to the regulator. I agree with the latter approach due to the greater competiveness of the initial product.

Also I would be considering the use of such a system for ship propulsion. a direct cycle gas reactor would be compact enough for use on a ship (comparable to LWR once the power conversion technology is included). The gas cooled reactor has the advantage that it can reject its decay heat without relying on convection, and as ships can capsize convection can’t be relied to work if the reactor was put into different orientations. Such a system would be intrinsically safe in all circumstances and can use the hull of the ship as the ultimate heatsink which is always connected to either the atmosphere or the ocean.

Or you could design a direct cycle gas cooled reactor running on CO2 as the first step: lower temperatures and concomitant lower efficiency, but there is an immense experience amount of experience running CO2 cooled reactors (in the UK, of course).

unfortunately when you start looking at efficiencies with real gas turbines temperatures have to be in excess of 650C just to make it turn without much net power out, and generally in excess of 800C for a simple cycle to have reasonable efficiency (25%) (an ICR engine can operate with good efficiency down to around 700C). CO2 coolants require the carbon moderator to be too cool for it to work with TRISO fuel due oxidation problems for it to be any use in a direct cycle. And again you would need to design a new set of turbo machinery.

Or you could operate an Adams Engine in the fast spectrum, perhaps?

Would that greatly reduce the formation of carbon-14?

interestingly there was another reactor concept which uses steam as the coolant so that liquid water never exists in the reactor. It never quite progressed to a working reactor but still it has a number of interesting properties, firstly the pressures are much lower than that of supercritical reactor which it would be most closely related and far lower corrosion issues to that of supercritical reactor. The steam is dry and of higher temperatures than in a conventional LWR offering better turbine efficiency. No issues with boiling water causing a variation of thermal conductivities, and if used in ship propulsion no issue of free surface effects in the reactor.

The basic design has the steam constantly circulating through the reactor, a takeoff of steam from the hot leg is then used to drive a turbine, which is then passed through a condenser and then injected back into the steam circuit heading back into the reactor causing it to immediately vaporise. Not sure why it was never investigated further

Yes, that certainly is interesting: a gas cooled reactor where the gas is superheated steam.