Update on Babcock and Wilcox mPower Modular Reactor

During the ANS Winter Meeting, I stopped by the B&W booth and had a chat with some of the booth representatives about the progress that the company is making on its mPowerTM modular reactor. We had a good conversation about steady progress and a project that is meeting its planned milestones. I received a promise for an updated set of materials and graphics, but in the meantime I also stumbled across a detailed article on Nuclear Engineering International titled B&W’s Baby that provides a good deal of information that has been released in the months following the company’s initial announcement in June.

The article talks about the fuel cycle, the steam generator configuration, the way that the primary system is fully contained inside the pressure vessel with no external piping, the way that the fuel storage system will work, the way that the control rods are integrated with the fuel assemblies to eliminate the need for dissolved boron, and the advantage that B&W has as an American manufacturer with the already certified capability to manufacture large pressure containing vessels the size of the one that they propose to use for the mPowerTM. (The pressure vessel for that system is essentially the same size as a steam generator for one of today’s operating light water reactors.)

Here is an interesting passage from that article that made me smile and supports my optimism that the mPowerTM is on a trajectory that will lead to a successful licensing application and initial market introduction during the next ten years.

B&W’s biggest customer, the US military, continues to rely on the company for nuclear submarine reactors. Mowry says that US military technology protecting its nuclear reactors will not be transferred to the mPower reactor project, partly because they are secret, and partly because the performance requirements of civil nuclear reactors are much less stringent than in submarines. Still, the company is in a privileged position to use the same manufacturing lines, and the same brainpower, that build the Navy-spec NSSS. “The factories are already there. Our additional investment for the initial stages of market adoption are minimal,” Mowry says, adding that if the project takes off, the company would be prepared to invest in new manufacturing lines.

I can offer just a bit of color to that description that is based on my professional associations with B&W’s primary customer. There is little chance that the company would have made that statement without having received permission from Naval Reactors; that relationship is too valuable to put it at risk. Despite all of the frustrations that I have had over the years in dealing with NR, it is an organization that encourages its contractors to take great care and do a lot of homework before making any delivery promises. It has also developed a solid reputation as an organization whose contractors deliver real equipment that works reliably, not paper reactors.

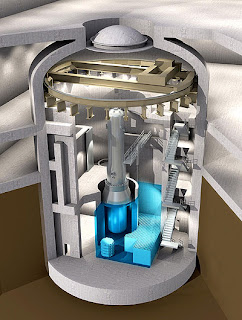

Image Credit: Image used with permission from B&W. Here is the caption provided – A single B&W mPowerTM nuclear reactor module inside its own independent, underground containment.