Avoiding Hurdles By "Going Small"; More Reasons for Smaller Nuclear Power Projects

On the second day of the Nuclear Construction Summit, I listened to a series of speakers including independent project consultants, financial services providers, lawyers, ratings agencies, and bankers. In nearly every presentation, I heard or saw evidence supporting the idea that very large, expensive, complex projects can be risky without a lot of attention to detail. The presenters talked about the importance of proper planning, the almost imperative need for strategic partners, the utility of good contract language, the importance of clear negotiations about risk sharing and the need for effective government support to enable it all to happen.

Following almost every presentation, I asked the speaker what they thought of the notion that they had just made an effective case for considering small or medium sized reactors in order to reduce the project physical and financial complexity. After all, if a huge stumbling block is that a project is too large to be financed within the balance sheet capacity of an investor owned utility with a market capitalization of a few tens of billions of dollars, one way around that is to propose a significantly smaller project with a price tag that is 5 or 10% of the current proposal.

If the management of a matrixed organization is challenging, co-ownership or joint ventures can be even more problematic, so choosing a project size that allows independent action has a benefit. If there is concern about the impact of market changes over a 8-10 project decision cycle, one way to reduce risk is to build a smaller increment of power capacity in a shorter amount of time. If there is concern about the ability to keep a stick-built project on schedule, one way to reduce the risk is to complete most, if not all, of the power generation machinery in a factory with a well trained work force.

About half of the speakers acknowledged the attraction of thinking about smaller projects and cautiously expressed their interest in seeing how systems like those proposed by Hyperion, NuScale, Toshiba and B&W are received by the NRC. Most of the rest indicated that they did not think it was a good idea to go small; from their point of view that did not get rid of the most important sources of uncertainty and complexity since the smaller projects have not yet started the process of obtaining an NRC license.

In the hallway during breaks, I had a number of interesting conversations initiated by people who appreciated my line of questioning and wanted to learn more. I am not sure how many of them have carefully studied what is happening in the small and medium sized reactor space; some thought that the concept was simply a bit of hype spread by people who just do not understand how difficult nuclear power can be. One guy was very insistent that I knew nothing about the industry since I had never worked at a commercial plant and seen the challenges up close.

There is still a lot of skepticism in the industry about any real effort to build; many of the attendees at the conference were long time industry veterans who have been hearing about a “Nuclear Renaissance” for more than a decade but had not yet seen strong indications that it was happening. They have a hard to overcome certainty that somehow the NRC will halt any significant innovation and they are placing much of their hope on government action related to carbon emissions and loan guarantee programs to get just a little motion started.

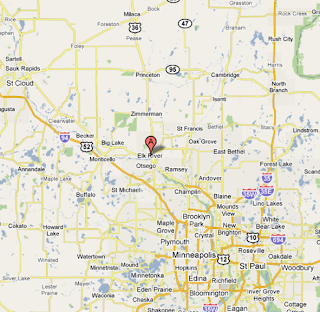

At one coffee break, I engaged with a group of people who were talking about the environmental and emissions control challenges faced in their company’s fossil fuel division. I asked if they had ever heard of the concept of coal to nuclear conversions (see Jim Holm’s thought provoking site at http://www.coal2nuclear.com). They scoffed, so I mentioned a specific plant that had once been a coal plant, converted to a nuclear plant, and then converted to a waste to energy plant. They looked at me like I was from Mars and then became sure that I was nuts after I mentioned that I could not remember the exact name of the plant but I knew it had the word “river” in it and that it was located in Minnesota.

No one likes to be thought of as crazy, but I did not have time to do the research during the coffee break. However, last night, I did a bit of searching and recovered my memory from the distributed resources available on the Internet.

The plant I was trying to describe to that experience bunch of nuclear industry professional skeptics was the Elk River Station. It began its life in about 1950 as a coal and oil burning power plant. In about 1958, the plant owner – then the Rural Cooperative Power Association – engaged in an agreement with the Atomic Energy Commission. The AEC would provide a 58 MW thermal atomic steam source, the RCPA would provide a site and turbine generator. The idea was to demonstrate how an atomic heat source could provide a reliable source of power in areas where fossil fuel costs were higher than average due to the expense of delivery to rural or remote areas.

The nuclear heat source was built by the company that later became known as Allis-Chalmers. It started operation in 1964. It was a boiling water reactor with fuel consisting of about 4% U-235 dioxide and 96% thorium dioxide. The total core size was 1.5 meters tall by 1.5 meters in diameter.

The Elk River Nuclear Station operated as an AEC demonstration plant from 1964-1968. At that point, the demonstration had been completed and shown that atomic heat could indeed be used in a conventional steam turbine even at a relatively small size to supply the needs of an area with relatively expensive fossil fuel. However, the plant was never cost competitive with fossil fuels, partly due to its unique design and its associated AEC research projects. The plant was converted back to coal and oil heat in 1968.

The nuclear island for the plant was dismantled and removed from the site in the early 1970s. Though this demonstration project does not prove the economic case for small nuclear plants, it does prove the technical possibility that a nuclear heat source could be used as the boiler replacement for a coal, oil or gas fired power station and make use of the existing turbine, generator, transformers, water supply and transmission lines. It was not right in 1968, when oil sold for about $3 per barrel, there was no Clean Air Act in effect, and no one had even started to think much about global CO2 emissions.

However, since most of those initial conditions have changed considerably, it is worth doing some additional analysis to see if a series produced – vice one of a kind – nuclear heat source could be a better choice to repower existing coal plants than a completely untested concept like direct removal of most of the CO2 from a combustion product waste stream. According to some recent research by people who have a strong interest in developing Carbon Capture and Storage (CCS) systems, that process is going to be very expensive.

Clean coal would add 78 percent to the price of electricity, according to a report released Wednesday from the Global Carbon Capture and Storage Institute.

The institute, established by the Australian government, includes the United States, the United Kingdom and J

apan among its members.Without policies and legislation to assign a value to carbon dioxide, the report says, the energy sector has a “limited incentive” to install carbon capture and storage facilities. What could make CCS work, it said, is the “field of dreams” or the “build it and they will come” option: governments “working in partnership with industry and the community to develop, finance and build common user transport and storage infrastructure.”

Even if you could develop CCS, safely storing billions of tons per year of CO2 seems like a much harder task than storing hundreds of tons per year of used nuclear fuel.