Nuclear-Powered Trans-Ocean Shipping – 3rd place in New York Advanced Energy contest

I received an update from Benjamin Haas, the SUNY Maritime student who has been working on nuclear powered ship designs from a complete systems perspective for the past three semesters. He and his team have not just focused on the technical aspects of designing a power plant and a ship that could take full advantage of that plant; they have also paid careful attention to regulations, politics, and economics.

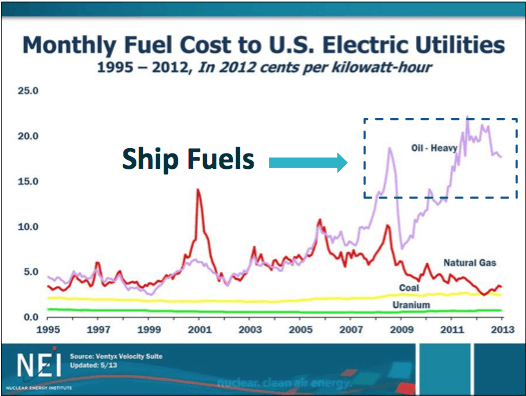

Benjamin entered a poster summarizing their conclusions into a contest at the New York Advanced Energy Conference and earned 3rd place. Here is one of the most thought provoking graphics from the poster.

Nuclear-Powered Trans-Ocean Shipping

Benjamin sent me and Guilian Crommelin (a retired Dutch Navy Captain with whom I have been communicating since 1994 about our shared interest in nuclear heated gas turbines) a report on his experience at the conference. He gave me permission to share that report with you.

Please note the discussions with visitors to his poster display. There is a great deal of interest in nuclear energy; I hope more people are inspired by the effort Benjamin is making to share what he has learned about the value of nuclear energy as a tool for solving some of humanity’s most challenging problems.

From: Benjamin Haas

Rod, Gulian,

I am pleased to report that I received 3rd place among the undergraduates for the New York Advanced Energy Conference poster session. I have been busy with finals and completing our ship design report since last Monday. The conference was very useful for me because I got experience speaking to people, some of whom are professionally involved with energy, about nuclear power.

The venue was fairly large and mostly a New England demographic. The plenary speaker was an author of a book titled “The Coming Energy Revolution”. He discredited Malthusian claims and conveyed optimism for the economic and social gains of enabling energy usage for the developing World.

I felt like I was among friends because the people I spoke with, students and professionals, are very concerned about how to get environmentally benign, low cost energy to the rest of the world. My impression is that that they would be open to learn about nuclear power from the standpoint that it can solve many of the problems that deeply concern them, but they simply don’t hear this narrative about nuclear power. A topic addressed at the conference was that renewables are not making fast enough gains. My interpretation of this is that all they hear about are renewables, batteries, and efficiency and are running into their limitations; most of the graduate posters were about batteries and net-zero homes (houses that are completely self sufficient for heating and electricity). Definitely a very important concept for developing nations, but not when countries increase their standards of living, or for industrial activities.

Students and professionals asked me about terrorism and safety. I explained the gas-cooled reactor concept, careful not to give them the impression that light water reactors are unsafe. I spoke about my ideas from the perspective that PWRs are not good for competing directly with oil and gas in replacing the diesel engine and gas turbine. One challenge I had was introducing the commercial maritime industry to people who are unfamiliar with it. I found that a common ground was the upcoming IMO’s sulfur emissions limitations, to which a number of people nodded their head, impressed with the information, and said, “That’s good!”

Here are some paraphrased conversations that I had with people at the conference about my research. I focused on keeping my tone firm but educational:

Student: “I think nuclear power would work great for ships and what you have here is a great idea, but there’s one reason these would never be accepted: terrorism.”

Me: “What kind of nuclear accident do you believe terrorists can cause with these reactors?”

Student: “There’s spent nuclear fuel inside.”

Me: “They can’t access it. It is sealed inside the reactor vessel. Even if they did open it up, the radiation would kill them. It’s like it is protecting itself.”

The student started to reconsider his concerns. Towards the end of the event (he was part of the poster session), he seemed cautious, but not discouraged about nuclear shipping.

Professional: “This is very interesting. I was a public policy major in school and I interned at the NRC When I see nuclear power I think of the social concerns, the stigma it faces.”

Me: “That’s cool you got to work for the NRC. I hear they are one of the most effective federal agencies. It’s interesting you mention public policy because the misconceptions and fears about nuclear power are starting to look like a social problem; it’s taught growing up, you see it in the media, TV shows, hear it from friends and family.”

Professional: *Nodding his head* “I see what you’re getting at. That’s interesting.”

Patent attorney: “I’m a patent attorney and I’m a graduate from King’s Point. I don’t usually see innovative ideas like this from the maritime industry. Typically they adopt technologies from elsewhere. Here is my card.

Me: “I believe that the adoption of nuclear power for ships is the intersection of the commercial maritime industry with broader world problems.”

Student: “I spent a lot of time learning about nuclear power myself and I know it is capable of so much and we should use more of it. I just wish there was some way of dealing with the waste.”

Me: “There is; nuclear waste can be recycled. Spent nuclear fuel can be reprocessed and put into fast reactors and turned into electricity. It is currently available technology. Geologic storage of the remaining waste is a viable solution.” I then spoke about Oklo Africa and stabilizing the materials into glass. His eyes lit up when he heard that nuclear waste can be used.

I handed a few of those Radiation is Safe within Limits pamphlets. I only handed them out to people who were interested; they were expensive and I did not want to waste them!

We’re almost done with the nuclear ship design. I am proofreading, checking the math, and formatting it now; 140 pages, over 30,000 words, 3 semester of work.

Gulian, during our presentation to the class on our NEREUS-powered container ship, a material scientist/mechanical engineer said aloud that (the NEREUS reactor) is the most innovative idea he has ever seen.

Sincerely,

Benjamin Haas

Congrats to Benjamin Haas. It is encouraging to see the extent of issues which he has confronted. I am inspired by his solid approach to the issues surrounding his group’s project.

Thanks for sharing this story.

Great work Benjamin, good to hear about your success and your positive discussions.

Tell Ben I’ll send him more Radiation is Safe within Limits brochures if he emails me an address.

” I explained the gas-cooled reactor concept…”

Gas cooled reactors are great for space craft propulsion, too:

http://www.lanl.gov/science/NSS/issue1_2011/story4full.shtml

http://www.personal.psu.edu/djm5200/NERVA.html

https://www.youtube.com/watch?v=WoiVej1rccs

Ben did a fantastic job. It is hard to think on your feet to field questions and “Monday morning quarterbacking” a discussion/debate/argument is all too easy.

Still, Ben’s answer about nuclear waste (“There is; nuclear waste can be recycled. Spent nuclear fuel can be reprocessed and put into fast reactors and turned into electricity. It is currently available technology. Geologic storage of the remaining waste is a viable solution.”) could be expanded at a future opportunity to include DUPIC (Direct Use of PRW In CANDU) fuel — there the spent nuclear fuel is not merely used in “currently available technology” but in currently EXISTING reactors. Also, much of the “remaining waste” can be used and not stored (Sr-90 in RTGs is the clearest and biggest example).

@Rick Armknecht

Nearly all of the isotopes in used nuclear fuel have unique, useful physical properties. For another example, Cs-137 has been used in irradiators; it is a good source of gammas that can perform similar tasks to C0-60.

NNadir, a professional chemist, has written extensively about the ways one could extract value from what people no consider to be dangerous, expensive to store “waste” material.

I spoke with him about his research and ideas in several different Atomic Show podcasts.

Here is one example: – https://atomicinsights.com/the-atomic-show-106-nnadir-discusses-ruthenium-rhodium-palladium-plus-other-valuable-nuclear-wastes/

Rod,

I listened to the podcast. Thanks.

As for extracting full value from spent nuclear fuel, I wonder if Sen. Reid could do something useful. It is no secret that he absolutely hates the law requiring disposal of nuclear waste in Nevada. If there is a higher value for fission products than disposal (and there is), then the disposal at Yucca Mountain becomes a moot issue. DUPIC is one possibility (perhaps the Canadians can take it, use it and keep it for 20 years or so before returning it — sort of a radioisotope “float,” to borrow a term from finance). I’m sure that there are plenty of other opportunities. Here in Utah, the Huntsman Cancer Institute uses an Sr-90 “cow” to obtain Y-90 which they place in spheres that are placed in lobes of cancerous livers. Pretty good results.

I was at a dinner for a local Maritime society last week and I was speaking with a woman who runs a company that handles quarantined items coming from ships. She was telling me how they were deciding on whether to use Co-60 or Cs-137 for sterilization. She said they were probably going to go with Cesium. Can anybody speak about the benefits of using Cesium over Cobalt? All I can think of is that you need much more Cesium.

@Rick Armknecht;

Thanks for the reminder. I will remember that for the future. My feeling is that many people have a latent curiosity about nuclear energy, but it goes unsatisfied. I am interested in finding out what the actual value of current spent fuel is. Attaching a $/gram figure to it could really open peoples’ eyes.

I assume you’ve seen Kirk Sotensen’s wonderful Google Tech Talk on this subject?

http://www.youtube.com/watch?v=rv-mFSoZOkE

The big advantage you get using Cs-137 instead of Co-60 is that the Cs-137 has a much longer half life so you don’t need to replace your source anywhere near as often. The big disadvantage is that the radiation from Cs-137 has a much lower energy so it’s harder to get uniform irradiation due to increased self shielding. Co-60 can also be cheaper than a Cs-137 in the short term, but depending on the situation exact costs are highly variable so it can go either way.

My wife and I went on a Carribean cruise in March, and when I saw the sickly brown plume spewing from the funnel and hanging like a venomous fog over the crystalline sea as hundreds upon hundreds of miles fell away behind us, I leaned against the back railing and thought about the Adams Engine, and felt sad.

God willing, people like these students and their mentors will dispel that fog some day.

I am also advocating nuclear propulsion for cargo ships. What this article perhaps accidentally omitted was that the current (since 2007) hot trend of shipping is “slow steaming”.

Slow steaming means ships are getting bigger but also slower. Cost of the fuel is the limiting factor here, there is no other option than to slow to 18, perhaps 14 knots or less. Financially this means that the producers and traders are once again having warehouses which were determined to be ineffective a long time ago. Now the only difference is that the warehouses are floating slowly around the seas.

Could there be a new business opportunity here?

Nuclear energy would be a new “ecosystem” in maritime industry. As I am a Finn I say that non-nuclear shipping companies would face their “Iphone” moment which Nokia faced here in Finland – i.e. sudden realization that the competition is doing something much much better than they ever can.

Now, what other advantage nuclear propulsion would have, other than cheap fuel?

Speed.

If one can have a 250MW nuclear power plant instead of 80MW diesel engine then the sailing is definitively something else than “slow steaming”. I am not a maritime engineer so I do not have formulas available but if a nuclear powered aircraft carrier can achieve 35 knots then I am quite certain that a well designed nuclear cargo ship can reach the same speed.

This would be the double killer “app” for any company interested either building cargo ships or operating them. It is a no brainer to realize that if there is zero-carbon energy source which makes things go at double or triple speed you are going to win every deal in shipping.

Well, perhaps the most hard core greens would establish their own “Eco Diesel” shipping companies just to avoid the evil of the fission! However I am certain that ordinary consumers and producers would vote with their wallets.

I hope someone takes the risk and builds a fast nuclear cargo ship and proves that all this is easily achieved. It is very likely that the nuclear propulsion may have many other unseen advantages, just like the smart phones.

@Tuomas Huovinen

Thank you for your comment. It is always good to hear from new readers with new perspectives.

You are right about the importance of speed. For a ship that means more power – it takes 8 times as much power to move at 30 knots than to move at 15 knots. That means that the specific fuel consumption increases by a factor of four. If burning bunker oil that is a considerable cost problem; it is even worse if burning refined, low-sulfur diesel fuel. From an environmental point of view, fast ships burning bunker oil are terrible, it’s a little better if they are burning refined diesel fuel.

If the fuel is uranium or thorium, however, fuel cost is exceedingly low and air pollution is non existent — remember, nuclear power is clean enough to run inside sealed submarines!

You might be interested in reading some of Benjamin’s more detailed work, available with links from the following:

https://atomicinsights.com/suny-maritime-student-advocates-commercial-nuclear-ship-propulsion/

He and his SUNY classmates are well aware of the importance of speed in merchant ship productivity.

The data I can find on the Emma Maersk container ship is that the engine is rated at 80,080 kW giving a service speed of 25.2 knots. What fraction of maximum power this is, is not stated.

If cruise is at 75% power and power is proportional to speed cubed, operating the Emma Maersk at 40 knots would require just over 240 MW. A nuclear powerplant operating at 25% thermal efficiency would require a thermal output just under 1 GW.

This report on TRISO fuel claims a power density of 6 W/cm³, or 6 MW/m³. Sqeezing 960 MW out of such a reactor requires a core volume of 160 m³, or a cube roughly 5.5 meters on a side.

I find a source claiming the Emma Maersk burns 16 tons of fuel per hour. Given that bunker fuel is roughly the density of water, it would burn a volume equivalent to that core in about 10 hours. I suspect that a ship the size of the Emma Maersk would gain quite a bit of useful volume and cargo-carrying capacity if it was nuclear powered, as well as being able to cruise some 60% faster than its oil-burning cousin.

@E-P

That’s a good bit of analysis that does not conflict with the work that I did in support of the Adams Engine. One bit of refinement is that each core of a pebble bed reactor based power system should be limited to about 300 MWth in order to remain well within the limitations of completely passive decay heat removal in the case of a station blackout or other loss of coolant flow. The Chinese HTR-PM project has imposed another margin of safety by aiming for 250 MWth on the first installation – but I suspect they indent to perform testing that will enable that limit to be raised.

Another number that is a useful thumb rule is that a good marine diesel engine can achieve a thermal efficiency of roughly 50%, giving it a specific fuel consumption of roughly 160 gms/kw-hr. For back of the envelop calculations giving diesel the benefit of the doubt, I use 150, if I was designing a ship and needed to make sure it had enough fuel to go the distance, I would use 200 or 250 gm/kw-hr.

An alternative to multiple cores is to change the form factor for better heat dissipation. I can see heat pipes going to the outer hull as a way to keep the shield from exceeding temp limits.

@E-P

Heat pipes might work just as well, but I’m a bit of a fan of the multiple reactor idea. It is analogous, at least in my mind, to the way internal combustion engine total power is often built up by adding more cylinders. This is especially true in very large marine diesel engines where there are physical limitations that prevent making ever larger cylinders.

Rod,

I have a very basic question about the Adams Engine: why not use CO2 instead of N2? Is it just that CO2 behaves too differently from air to use existing gas turbines? (Having read enough of your work, I understand that my use of the word “just” in the preceding sentence might be understating something very significant.)

@Rick Armknecht

There are two reasons:

1. N2 gas properties are nearly identical to air and can use the same turbomachinery without modification as long as proper attention is paid to the potential for nitriding. (That is pretty straightforward.)

2. CO2 will begin to break down into CO and O2 at temperatures not much higher than those that might exist in an HTR under both operating conditions and accident conditions http://carbon.atomistry.com/decomposition_carbon_dioxide.html

There is, of course, a deep well of experience in using CO2 as a reactor coolant in the UK.

One interesting note: Several engineers I’ve spoken to over the years about the Adams Engine lose a little interest when they realize how firm I am about the need to use ‘off-the-shelf’ components. Either they like the process of creating something entirely new or they want to develop technology that has a potential for strong patent protection.

The only part of the Adams Engine that I could think of that was not prior art was issued a patent, which I allowed to enter into the public domain about ten years ago.

http://adamsengines.blogspot.com/2009/08/throttle-valve-control-for-fission.html

Rod,

As I understand it, an AGR produces CO2 at 640 degrees C and at 580 psi and an Adams Engine produces N2 at 300 psi. In your estimation, is that an insufficient margin to avoid decomposition of the CO2 in an accident?

As for operation of turbines designed for air with CO2: is the relative weight (28g/mole vs. 44g/mole) the issue? Would it cause a catastrophic failure if CO2 were used — or would it diminish efficiency a bit?

@Rick

You neglected to mention temperature. We want to start with a core outlet temperature of at least 800 C and believe that an improvement path is steady material improvements that allow that temperature to continue rising. That is the same efficiency path taken by combustion turbines, by the way.

I’m digging deep into memory banks for a decision I made more than 25 years ago, but I think the other big consideration was the fact that N2 is one of the cheapest industrial gases around with a ready store of gas almost as good to use for emergency coolant if required.

http://adamsengines.blogspot.com/2009/09/nitrogen-n2-gas-cooling-for-closed.html

Rod,

OK — 800 C is how hot the Adams Engine would get. I hadn’t known that.

Yes, that is far from 640 C.

Still, new materials are being developed. The UK has developed NIMONIC Alloy PE16, which has been proposed as cladding in a CO2 cooled fast reactor. In that design, the peak clad temperature would be 730 C.

No doubt that CO2 is more expensive than N2 — but compared with Helium, I suspect that they are similarly cheap.

@Rick Armknecht

Remember I said that 800 C was the goal for the first series of Adams Engines. That is an undershoot of the 950 C achieved in the German AVR program.

The path of improvements in efficiency and power density – leading to lower costs – is through even higher temperatures. It makes sense to pick basic components and chemicals that have room to move up the ‘S’ curve and are not already pushing limits at the entry point.

That is also one of the reasons that I like low pressures. In fact, the operating pressure of the initial versions would be roughly atmospheric pressure – 101 kPa – for most of the system. At 800 C the optimal Brayton cycle pressure ratio is about 7 or 8 to 1, so the highest pressure in the system would be substantially less than 1 MPa. If needed pressure reduction would be a simple matter of turning off the compressor.

By the way, we looked hard at a rather unconventional Brayton cycle that was not an aeroderivative engine. It used electrically powered centrifugal compressors that look a lot like turbo-chargers that were completely separate from the turbo expanders (http://www.ge-energy.com/products_and_services/products/turboexpanders/) used to produce the power. That layout removes a number of constraints associated with aeroderivative machines but still uses off-the-shelf components in wide industrial use. We just looked on a different shelf than usual. (And yes, there is a little ‘royal we’ in that last paragraph.)

Rod,

Your off the shelf philosophy of engineering is why I think that your design is one of the best. I look forward to the fuel being available. This will drive the cost down and make factory manufacturing really possible.

How close is the fuel to being ready for use?

O.K., Rod — thanks for setting me straight on that.

Your concept is so elegant and it is a shame that it should snag on Nitrogen’s 75 millibarn thermal neutron capture cross-section and it’s occasional transmutation to Carbon 14. I was looking for a way to get most of the benefits of the Adams Engine without those snags.

As regards the problems seen with N2:

(1) Has there been any consideration of mitigating the thermal neutron affinity by operating the reactor as a fast reactor or as a reduced moderation reactor?

(2) Would it be feasible to scrub the Carbon 14 from the N2? If N2 becomes CN (and not separate Carbon 14 and Nitrogen 14 atoms), then the inherent reactivity of cyanide should present an opportunity to “fix” the CN for disposal or some useful function.

@Rick Armknecht

Another reader suggested to me that there is another naturally occurring isotope of nitrogen – N-15 – that has essentially no neutron cross section. It is pretty rare, with a natural abundance of 0.368%.

There are chemical ways to separate the isotope and it is in industrial use in agricultural research and as a target for O-15 production.

I never got around to performing any research on production costs.

It is also feasible to separate C-14 from N-14. I do not think that CN is the result of the interactions.

@Atomikrabbit;

Thanks for the video! According to Kirk Sorensen, current SNF may be practically worth about $1.0/gram, after reprocessing and separating, and most of that would be from Plutonium. That isn’t small; $1 million/tonne.

@Tuomas Huovinen;

I am glad to hear your support of nuclear shipping. If you refer to the graph on the bottom right of my poster, you will see the freight rate of the slow steaming comparison vessel on the U.S.-Europe route. Slow steaming is not simply a result of rising fuel prices; for a long time, slower speeds would have resulted in lower freight rates, but cargo owners wanted faster delivery times and the supply-demand balance was in favor of higher freight rates. The current oversupply of ships is the biggest influence on slow steaming.

I believe high speed (30+ knots) will be the exception, not the rule, because the financing and fuel costs increase at a much faster rate than the revenue from carrying more cargo per year. My research looked at a container ship on the U.S.-Europe route that is only 33% faster than a slow steaming vessel. The results are that it can be cheaper than slow steaming depending on the LNG/Low Sulfur Oil price, not including additional value for the faster service. Other than being nuclear, it is a conventional service option that does not depend on cargo owners paying a premium for speed. The problem with past proposals for high speed shipping was the dependence on having a large enough customer base who would pay that premium.

Nuclear shipping should primarily be marketed as being cheaper than all other hydrocarbon options in conventional services. High speeds and trans-Arctic routes would come AFTER it has been accepted by the general shipping industry. That is the simplest way because it creates the largest possible market from the start. It also makes the nuclear reactor these ships will use compatible with the shoreside diesel engine/gas turbine markets (5-30 MWe). The NuScale, for example, is not going on a ship.

@ Benjamin Haas

Has there been any investigation of the feasibility of a nuclear powered “integral tug” for merchant vessels? What I envision is a vessel that provides crew spaces (and all associated hotel services), navigation and maneuvering capabilities, and (nuclear) propulsion — but does NOT include cargo space. The bow of the nuclear ocean-going tug has devices that permit a secure pairing with a second vessel that has ONLY cargo space. The stern of that second vessel has compatible devices for securing to the bow of the nuclear ocean-going tug (although “pusher” would be a more fitting term than “tug”).

There are benefits and disadvantages to the concept. The disadvantages are that the pairing of “tugs” and “containers” is an added complication both in terms of the technical aspect (the physical pairing) and the logistical aspect (having a “tug” at the port when the container is to be moved). The benefits are that the propulsion COULD be used at a higher capacity (if the logistics are well run) and the cost of having a ship in port would be diminished if it is only the “container” portion of the ship. Another benefit could be that an “anti nuke” port could be reached by the container: the nuclear tug de-couples a few miles out of port and diesel tugs bring the container that last few miles.

@ Rick Armknecht

Some professors from the University of Southampton took a brief look at exactly what you are talking about. The paper is available online via search engine and is titled: “CONCEPTS FOR A MODULAR NUCLEAR POWERED CONTAINERSHIP”.

I have not read through it completely, but it discusses the different kinds of connections between the “pusher” and the barge.

There is another kind of vessel called the LASH carrier that carries barges, like the Russian nuclear ship Sevmorput, but they were not economical against containerization. That is another potential arrangement other than having a detachable pusher.

Nuclear power units distinct from the load could be

1. Tugs, towing ships or rafts.

2. Pushers

3. Towed power units towed by electrically propelled ships..

All could be useful under different conditions. The ships could be the fastest trans-ocean carriers.