Why is nuclear energy an important influence on both natural gas and hydrogen futures?

The Feb 6, 2024 Energy Gang podcast was titled “A pause in US gas export approvals: a big win for the climate?US hits the brakes on gas exports!” It was described as a gassy episode with a focus on international natural gas trading, the impact of the Biden Administration’s pause on issuing new permits that…

Pro-nuclear advocates should stop bashing advanced nuclear

I wish I knew why some nuclear advocates feel that it’s worth their time to spread as much negative information as they can find about the potential utility and value of advanced nuclear…

Why would climate publications disrespect nuclear fission?

Here is another instance of climate reporting that treats nuclear fission as if it barely exists. Before COP28, Cipher published an “Exclusive” that led off with “The United States is working behind the…

Why did The Energy Gang overlook the newsworthy impact of nuclear energy on COP28?

The Energy Gang’s Dec 15 episode discussed the major outcomes from COP28. Ed Crooks (@Ed_Crooks), Dr. Melissa Lott @mclott, and Amy Harder (@AmyAHarder) completed the show without mentioning nuclear energy. That episode of…

Atomic Show #314 – Economies of scale for micro, small, medium, large reactors – with James Krellenstein

James Krellenstein is a physicist, consultant and nuclear energy historian. He is currently employed as a senior advisor to Global Health Strategies. He started up their decarbonization practice with an emphasis on nuclear…

Atomic Show #314 – Economies of scale for micro, small, medium, large reactors – with James Krellenstein

James Krellenstein is a physicist, consultant and nuclear energy historian. He is currently employed as a senior advisor to Global Health Strategies. He started up their decarbonization practice with an emphasis on nuclear…

Atomic Show #313 – Stefano Buono, Founder and CEO of Newcleo

Stefano Buono is a physicist and the successful founder of Advanced Accelerator Applications, a multibillion dollar company that pioneered the use of several therapeutic medical isotopes. After making several people very rich, including…

Atomic Show #312 – Tyler Bernstein, CEO Zeno Power

Zeno Power makes cost-effective radioisotope power systems (RPS) for some of the most challenging environments in the solar system. Its systems use a proprietary package that allows a wider variety of isotopes to…

Bechtel will “pursue” accelerated mPower development

I’ve relearned a valuable lesson — read press releases and other PR material closely, paying special attention to wiggle words. On Friday, March 4, Bechtel issued a press release titled Bechtel, BWXT to…

Update from Hyperion Power Generation Chief Operating Officer

Yesterday morning I wrote a post titled Where is Hyperion Power Generation headed now? By the time I was ready for a lunch break, I had received an email from the Chief Operating…

SL-1: Designed for Remote Power and Heat

SL-1’s mission was to provide power to radar stations along the northern perimeter of North America; a series of such stations was known as the DEW (Defense Early Warning) Line. The Army’s designation…

What Does Westinghouse Bankruptcy Mean To Nuclear Energy Innovators?

Attendees at the 7th Annual International SMR and Advanced Reactor Summit in Atlanta, GA were intensely curious about the effect of Westinghouse’s decision to enter into a Chapter 11 bankruptcy reorganization effort. They…

NAVIGANT analysis of Vogtle expansion provided to JEA in Sep 2017 understates fuel price risks

Aaron Zahn, the interim managing director and CEO of the Jacksonville Electric Authority (JEA), believes it is time to give up on the Vogtle expansion project. On August 17, he sent a letter…

Tragic day in South Carolina as 5,000 people lose their jobs at VC Summer

Yesterday, about 5,000 people working on the VC Summer expansion project learned that the owners had issued stop work orders effective immediately. They started the day with important jobs paying good wages and…

Power Politics – RFK Jr. Explains How Pressure From Activists to Enforce Restrictions on Coal Benefits Natural Gas

The above clip came from a lunchtime talk that Robert F. Kennedy Jr. gave to the Colorado Oil and Gas Association on July 8, 2010, during the Energy Epicenter conference. Aside: People who…

Smoking gun – German president of Environmental Protection Agency touts natural gas instead of nuclear

An article in The Guardian titled UK’s faith in nuclear power threatens renewables, says German energy expert is full of evidence of the alliance between natural gas salesmen and the advocates of unreliable…

Smoking gun: AEC told President Kennedy why coal industry was opposed to nuclear energy

It’s been quite a while since my last smoking gun post on Atomic Insights. It may be time to revive the series to remind nuclear energy advocates to follow the money and know…

Investing in Nuclear

Nuclear investments – enabling the transition to a low-carbon economy

Parnassus Versus Green Century: A Contrast in Styles

Cross-posted from Nucleation Capital June, July and August of 2023 were the three hottest months the Earth has ever seen by such a large margin, it left climate scientists agog. Climate disasters are abounding apace, with the U.S. hit by 23 large-scale disasters, a record-breaking year already. In Pakistan, extreme rainfall and flooding affected 33…

How Hot is Cold Fusion?

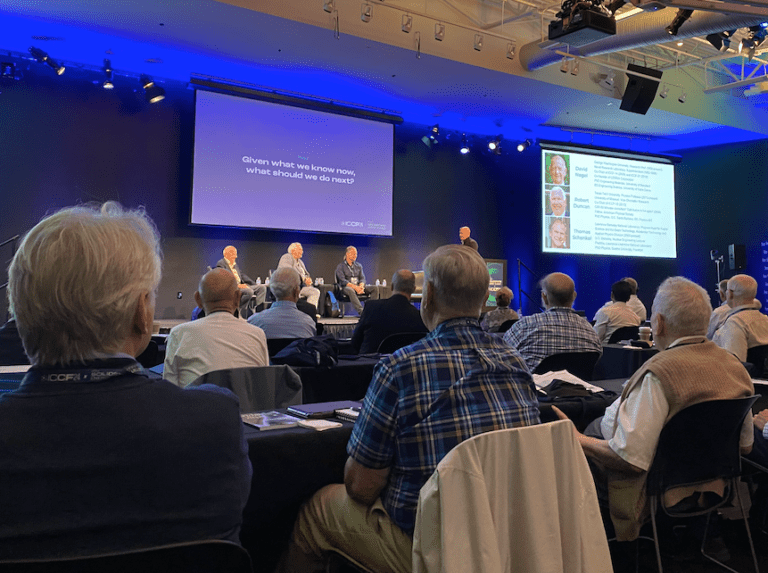

The 24th International Conference on Cold Fusion (ICCF24) was held at the lovely and spacious Computer History Museum in Mountain View, CA over four days in late July. As a venture investor looking at evaluating and investing in a wide range of advanced nuclear ventures, I was invited to participate and/or sponsor the event. While…

Rod Adams

Managing Partner, Nucleation Capital, a venture fund enabling broader investor access to a diverse portfolio of advanced nuclear energy and deep decarbonization ventures. Nuclear energy expert and former submarine Engineer Officer with nuclear propulsion plant experience. Founder, Adams Atomic Engines, Inc. Host and producer, The Atomic Show Podcast.