Prospective customers lining up at NuScale

A few days ago, Dan Yurman at Neutron Bytes published a blog post that is now titled Flash: NuScale executive says firm may build SMRs at Idaho lab. It was a follow-up to an earlier post in which Dan speculated about the Idaho National Lab’s potential as a good site for a new nuclear power plant.

One statement that Dan made in that original post, titled New life for Idaho test reactor, are SMR’s next?, stimulated Mike McGough, NuScale’s Chief Commercial Officer, to provide a gently worded correction.

Hey Dan. I read your post and you may not have seen that NuScale has long-ago announced that UAMPS will be the owner and ENW the operator of our first plant in Idaho and that we are in site selection activities as we speak. While we do not yet know exactly where the best site will reside, we do know that the DOE INL site has been well-characterized and that we expect to find possible choices there, once the screening of the state is competed.

That comment stimulated some additional discussion and clarification. Here is the sentence that attracted McGough’s response.

However, despite obvious speculation that emerges from time-to-time in Idaho Falls, none of the vendors has said so much as “boo” about these prospects, and at least so far none of the chatter would cause an investor to open publically (sic) their checkbook.

Over the past year or so, I have seen and heard McGough speak at conferences in Idaho, North Carolina and Northern Virginia. I travel far less frequently than he does; I think he lives out of a suitcase. It was not surprising to me that McGough would respond to someone saying that his company has not said “boo” about its project development efforts; he’s spent a lot of time giving talks all over the world to the kinds of audiences that can and will make things happen. I have no doubt that there are many developments that have not been announced yet, but even those that have been made public amount to more than mere hints.

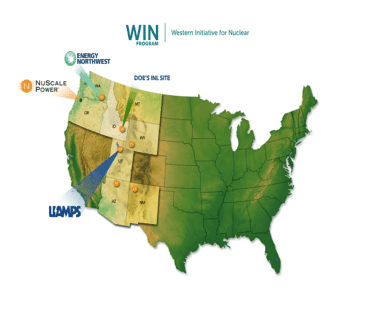

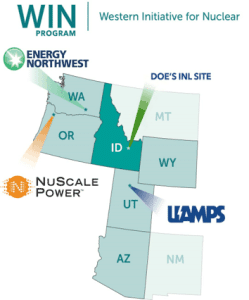

For example, on July 1, 2013, NuScale issued a press release titled NuScale Power’s Small Modular Reactor Chosen as Preferred Technology by Western Initiative for Nuclear which provided a reasonably detailed description of a well resourced program of regional development. It mentioned a demonstration project and additional interest in follow-on units. It included quotes from three governors of states that are interested in reliable, carbon-free generation and statements by two public utilities interested in deploying and operating NuScale power plants.

As I reread that press release, the date jumped out at me. I contacted Mike McGough and confirmed my suspicions. That press release was purposely issued on the day the submission window closed for the second round of funding under the Department of Energy’s small modular reactor program. NuScale obviously knew the details of its strong support earlier than that and included evidence of that support to reinforce the strength of its submission package.

NuScale, even though it is a startup, is apparently led by people who were wise enough to protect that critical information until after its competitors for the funding opportunity could not respond or attempt to steal its potential business partners.

When I spoke to McGough, he was in Paris at the World Nuclear Exhibition. After telling me that I had no reason to be jealous because he rarely gets a chance to do any sightseeing when he attends such events, McGough told me how busy his company’s phones have been with contacts from interested potential customers and suppliers. He attributed the recent increased rate of calls to recognition of the substantial advantages of his company’s product, the DOE selection of NuScale as the sole recipient in the second round of SMR funding, and the virtual disappearance of B&W mPower, Inc. as a strong competitor.

McGough shared the presentation that he was scheduled to give in Paris and gave me permission to use some of the material since it was being provided in a public forum. One of the new items to me was a bullet that said that NuScale now has a “line of sight” to its first 12 power plants, each of which would include 12 NuScale power modules for a total of 144 modules. Several months ago, I heard a NuScale presentation claiming that the company reaches ‘N’, as in the “Nth of a kind” economics after it has produced between 19-20 modules.

The demonstration project will be known as UAMPS Carbon-Free Power Project (CFPP). It will be owned by UAMPS (Utah Associated Municipal Power Systems), a consortium of 45 member utilities located in six states including UT, AZ, NM, ID, CA, and WY and operated by Energy Northwest, an experienced nuclear plant operator.

The plant will include 12 modules each rated at 50 MWe (gross) for a total plant output of 600 MWe (gross). After accounting for house loads of approximately 30 MWe, the plant will supply 570 MWe to the grid when all modules are operating. (Note: NuScale used to state that its modules would produce 45 MWe each, but has recently refined its estimates. The new number does not represent any design changes, but does show that its engineers tend towards conservatism and “underpromising.”)

There is obviously a major hurdle that must be overcome between now and firm contracts for actual construction. NuScale has not yet submitted its design certification application and there is no guarantees for how long it will take the NRC to review and approve that document. There are not even any guarantees that the NRC will accept the application as complete when it is first submitted or that it will eventually grant the license.

However, I believe the risk of non-approval has been carefully addressed and that the review period after submission should be reasonably close to the predicted 38-42 months. Jose Reyes, NuScale’s Chief Technology Officer, was an NRC regulator early in his career and several other leading engineers at the company are experienced regulators. I have little doubt that the company will submit a high quality application and will be able to provide excellent answers in response to Requests for Additional Information (RAIs).

Once the company achieves its design certification, there will be a line of customers that may not be as impressively long as those outside an Apple store when a new iPhone is released. However, each entity in that line would represent a possible $2-$3 billion sale. There is no reason for complacency or early celebrations, but cautious optimism is not unwarranted.

In addition, a study commissioned by the Washington State Legislature encouraged by business interests in the Tri-Cities/Hanford area concluded that $300m could be saved by using an SMR for the vitrification of cold war nuclear waste, instead of 45,000 gallons of diesel per day (!). Previous reportage indicated that Nuscale’s SMR was the focus. And the intent was to use this original plant to spur the use of the Tri-Cities as the worldwide manufacturing base for Nuscale.

http://www.tri-cityherald.com/2014/09/25/3171471/small-modular-nuclear-reactor.html

Washington Governor Jay Inslee and ex. Gov. Gregoire(both D’s) back this plan. Also, since this is a DOE site, I wonder if this might be a way to bypass the (ridiculous!) 42 month wait period while the NRC incurs humongous fees and salaries off of Nuscale before certifying their design?

“The plant will include 12 modules…”

Hmmm how does that work? Are there 12 reactor operators, 12 turbine operators, etc.? What does a 12-reactor plant control room look like?

If you need to supply 600 MWe, why would you do it this way? I could see it if the demand is growing by 50 MWe chunks, so you build the modules one by one over time. But then why centralize them on one site? Better to put them closer to the demand they’re serving.

Honestly, the SMR seems to me like an answer in search of a question.

@gmax137

Smaller machines and components are easier to build and transport. They also make it easier to maintain steady power output at a reduced level when demand is slack. They enable the same production lines to turn out machines that can serve small loads and large loads by simply adding modules. How do you think combined cycle gas turbines are arranged?

There does not need to be a one to one ratio of operator to reactor, especially when the reactors don’t even have coolant pumps. Turbines also don’t need full time operators.

There may need to be more staff per unit power, but operational costs are not the primary component of levelized cost in a nuclear power plant.

GTs can be arranged and ‘stacked’ in unlimited numbers. The are in essence a model of modular distributive generation. Some plants have as many as 8 GTs placed side-by-side. The more GTs, the lower the ration of workers to plant. Same with SMRs I imagine once the regulatory issues are fixed.

@JohnGalt

You are not paying for the technology. The moderate assistance that NuScale is receiving over the next 5 years will just about pay for the cost of NRC review fees and a portion of the cost of preparing the required paperwork. It will not pay for any technology development.

Natural circulation plants are not “de-rated forced circulation” plants. There is a lot of cost associated with leak-proof coolant pumps, pump cooling water, instrumentation, and reliable power. The avoided components take up space, require testing and surveillance, and expand the volume and complexity of seismic isolation.

Operating at 61% thermal efficiency while burning a fuel that costs $4.00-$75.00 per MMBTU depending on location and season results in a substantially higher fuel bill than operating at 30% thermal efficiency on a fuel that costs <80 cents per MMBTU all year long with few locational dependencies.

@JohnGalt

I don’t think “serious public involvement” provides any benefits for a complex engineering task. Is there “serious public involvement” in the design of an NFL football stadium, a metro transit system, or a system of tunnels like the Big Dig? All of those are nearly completely funded by taxpayers, yet those payers seem to recognize that they are not engineers or constructors; “serious public involvement” in the form of constant questions and forced redesigns would not add value to the project.

$217 million is the total over a six year period. Matching funds means that NuScale and its partners will have to put in at least that amount of money. It does not mean that the government will put in half of the costs since the cost of getting this project going will be far more than $434 million. The government has only agreed to provide a “fixed” amount, each annual increment of which must be appropriated each year.

Rod, I have been reading this blog for a long time, really enjoy it (haven’t donated yet, sorry!). I finally have a good topic to comment on.

Credentials, I work at an operating nuclear power plant. But, I had an internship in the NRC’s Advanced Reactor Program, and worked closely with some of these issues (or at least learned about them while I was there), so am happy to join the discussion now.

Gmax, you can find the NRC position paper SECY-11-0098 ‘Ops staffing for small or multi-module NPPS’. http://pbadupws.nrc.gov/docs/ML1118/ML111870574.pdf

Basically, the NRC is in a wait and see mode on Operator staffing. Originally, proposals from the likes of NuScale and mPower were something along the lines of ‘We will have 1 Senior Reactor Operator per x units, plus 1-2 spares acting as Shift Managers and Shift Technical Advisors’. The NRC is mostly amenable to easing or exempting current regulations that were built for Dual Unit large reactors BUT, sees their real job as asking the right questions about a staffing model, and ensuring that those questions are adequately answered. i.e. It may be reasonable for 1 SRO to monitor 4 small 50 MWe units if all are online (Mode 1), BUT, is it reasonable for 1 SRO to monitor 1 unit in start up, 1 unit defueled, and 2 units online? The NRC’s position is that their job is:

1) Know what the right questions are (they are working on it)

2) Ensure that the licensees understand what those questions are, and can properly address them prior to being licensed.

This as opposed to the old backfit model whereby if the NRC determines you need 2 additional SROs on shift at any time @ 5 shifts = 10 guys getting paid >120k per year = NRC essentially dictating an additional 1.5 million per year in unplanned O&M costs. The NRC wants to get this right prior to licensing so the licensees can understand their own business model.

As far as why 50 MWe chunks is awesome from my perspective.

Lower site vulnerability to trips/SCRAMs and can address problems more easily. Turbine trip causing reactor trip is a 50 MWe problem instead of a 600 MWe problem. This makes the monetary consequences of trips is way smaller.

Easier scheduling of maintenance and outages. Goes with the above. It is so much easier to take 50 MWe offline for 30 days to perform inspections and maintenance than it is to do it for 600 MWe.

The biggest potential downside I see is the commonality of problems. If their are 144 identical units in the country, and a safety issue is found, their are 144 units that have to come offline at some point and address the issue. Their is lots of opportunity in having identical sites all over the country, so an engineer or operator that trains on one can work at any other, but the idea of the number of possible latent common failure modes that could be introduced over time makes my skin crawl.

Luckily for us, the guys at mPower and NuScale have the benefit of a generation of Operating Experience to draw from (not to mention calculators), that will prevent so many of the problems our current fleet of Nukes is experiencing.

I’ll stick around in this thread so let me know if you have any other questions!

YoungNuke, thank you so much for that! I’m an ol’ GT and conventional thermal operator for PG&E (retired a few years ago). It’s great to have actual *operators* comment here!

A few points…the issue of clusters vs individual distributed modules.

1. Rod’s analogy with GTs is spot on. You will see clusters of 500MW units in one place or individual 100MWs units spread about. In this case you have to stop looking at it from the micro-generation POV (that is as one plant) and look at what the utility needs. For example, it’s a LOT easier to build a switch yard where all the generators…say “12 of ’em” feeding into what is effectively a transmission substation than building them in a distributed manner where finding transmission…and distribution hook ups can be VERY expensive.

A utility may need, say, 2000 new MWs. They have an existing, say, coal plant or GT cluster. Why not pop, say, 2 of these units there but there are some transmission substation closer to the load which has been growing unforeseen 40 miles down the road…pop one or two in there. The idea of SMRs is their ability to locate them closer than bigger units, or, to replace bigger conventional generation but subsituting out the fossil fuel plant, say, 3 900 MW gas burners with, say, 3 clusters of 8 each of these new SMRs.

2. Personnel and operations. Running more units with a bigger staff (within the paradigm of whatever regulations are allowed … see YoungNuke’s comments above) makes a huge economic sense…you can have, say, on SRO and a set number of COs and others for, every say, 2 units with operators able to fill in at the other units when needed, giving human resource schedulers a better and more flexible human resource management. with only 1 module, you still have the have the required operators and mtc. personnel. More IS better in this case.

3. Licensing. For each plant a set of licenses are required (cooling, siting, environmental, everything under the sun). You would need one set of licenses for EVERY unit if you set up these SMRs in a distributed manner. However, with a group license for one plant with, say, 12 SMRs, things can be cheaper and easy to manage, as more units can be added under existing licensees with likely only revisions instead of separate ones. (I’m more and more now willing to be a NRC Czar for regulatory reform, I might add :).

4. Pro-distributive. So the reasons then to be for distributive deployment of SMRs are obvious. They can literally be trucked in or barged into various closer-to-load transmission substations (they do this with peaker GTs). Pop two of these NuScalers in at a substation and you have instant power for an extra 100MWs. In fact, depending on load following capabilities, you can in theory drop them into distribution substations as well. That would be interesting.

David

@YoungNuke October 16, 2014 at 5:35 PM

Thanks for the input and especially that reference. I’ve followed NuScale for almost 4 years, and that ref contains sub-refs to almost every document involved in making the policy for how to handle the staffing issues, which may be the most challenging issue SMRs face. Design engineering is an established discipline, and NRC has a formal method for design certification. However there are traps in a total “wait and see” attitude by NRC on plant licensed operator staffing issues (and others). You know the problem, they are so outside the bounds of the current regulation (10CFR50.54(m)) on operator staffing it has become a big issue.

The actual plant design can only go so far until it is settled. You can’t do the final control room design until you are pretty confident in the number of operators. If NRC has heartburn with a manning proposal they owe it to the developers to speak up now. The currently “blessed” process, as you know, is it will be decided via exemption request, based on the outcome of the designer’s formal HFE program for the control room; based very heavily on the Task Analysis. NuScale is doing a preliminary scoping analysis for Task Analysis now.

But this is almost a catch-22. You can’t ID operator tasks without a plant design, vendor equipment manuals, ops procedures & EOPs, Tech Specs, Emergency plans, etc. And almost all those require a control room design first. It’s almost like a “can’t get there from here”, but NuScale is working hard, almost in a vacuum, lots of meetings but the operator manning requirements are totally in the dark.

Your ref doc (which i’ve read all it’s source docs) mentions stakeholder inputs and list NEI and ANS. This is the most important issue to come down the pike in nuke plants, for operators, since the beginning. Where’s the operator input? Are there no orgs that speak in a common voice for operators.

I have heartburn with the HFE plan being done on a simulator not required to be a plant replica (also blessed by NEI & ANS). Huh? That Sim can’t be used (won’t qualify) for an Op License exam, but is fit to use to get an exemption from operator manning regs? I don’t believe it. mjd (SRO operator, retired)

One more thing, both the station Emergency Plan manning and the station security manning are also decisions can can drive the design process. From what I have read, security manning may be driving the decision to bury the plant. An that is an extremely complicated design decision for an “off-shelf, standard design” concept. It makes them about “plant location specific.” I don’t agree “wait & see” is the right way to proceed.

This is great news. My town is a member of UAMPS and I would love to see this happen!

From the perspective of SMRs being a sensible alternative to the BUFF’s of today’s designs several questions form regarding the apparent intent to license it as if it were a Part 50/52 scale hazard and under the exclusive jurisdiction of NRC.

1) Why not go for first move in Richland and build it in the Hanford 300 Area – a lot closer to town and many technical support efforts; especially Northeast Utilities staffing?

2) How about petitioning to reduce the influence of the LNTH and ALARA Principle with their unreasonable costs of Emergency Preparedness and other factors which can strengthen per employee contribution by allowing more substantive annual dose limits?

3) Why not consider configurations at Regional Airports or Air Force bases, let someone else worry about site security and show that concerns about sabotage are being addressed in the overall design – and it would be greener!

4) Where’s the crawl, walk, run approach – it sounds like they’re going for a home run on the first time at bat – that is not going to inspire confidence with schedules or with NRC Reviewers

5) How will the oversight process work? It seems the plan is the ROP as usual; not a sensible conclusion? Part 52 is largely untested as yet for revitalizing the supply chain.

6) And what’s with a totally inexperienced lead buyer?

7) And finally, this has boiled down to putting all the eggs in one Development basket – where’s the Defense in Depth when the present management team stumbles.

If this technology is really viable economically, then it must break out of the present mold of regulation as usual. QC/QA on the acquisition side will be as important as ever, but its hard to see how you get the best talent, particularly in a younger generation of supply chain, putting your demonstration reactor out in the middle of nowhere. This is not 1955 with the Nautilus prototype.

Just from a political and regulatory viewpoint, I think LNT and ALARA aren’t going to change over night. Rod has an earlier article announcing scoping for NAS BEIR-VIII committee beginning late this year; I really doubt NRC will care to second guess that one. Further, what would the local headlines read if NUSCALE / UAMPS even so much as asked? Your point 4) crawl, walk run recommendation starts right here.

And is there any real operational reason to change at this time for normal reactor operations? How would substantially lifting employee dose limits increase productivity? What’s their actual exposure? Last I read USN SMR operators presently suffer from underexposure due to radon and cosmic ray deficiency. Are commerical operators any better off? Again clue me with a stick, but my impression is the benefit of more rational low-level radiation risk awareness will more immediately flow to such things as finally getting over TMI, public awareness of the popular (and governmental) over-reaction at Fukushima, and more tempered concern about radiation medicine, low-level waste disposal, and uranium mining.

Who knows? Someday we might even realize there’s a greenhouse gas problem to deal with.

I don’t see INL and Idaho Falls as negative for a first-of-a-kind new commercial nuclear plant. INL has the infrastructure, history, experience, and culture. I’d personally love to relocate to that area, and have no doubt there’ll be a lot of under-employed reactor engineers and operators who would pay their own carfare to be part of this thing.

Can each unit count as an external power source for the other units? Currently, there seems to be a rule that if external power from outside the plant is lost, then the plant must shut down, because (and this part seems kind of silly, so correct me if I misunderstood) if there was a problem at the plant, it would already be down one backup power supply.

With several independent 50MWe sources on site, why would one care if external power was lost? Of course, with the passive safety features, that old rule may be irrelevant any way.

It just seems ridiculous that when other power sources black out, the reliable nuclear reactor is expected to shut down because external power is no longer available.

Oh, and could one of these units be installed at each big nuclear power plant as a reliable back-up generator which does not need stores of diesel fuel?

That would not be a good use of a machine that can run on such low cost, low emission fuel.

Rod, anything that off-loads the main reactor’s systems from its own output (“hotel” loads) will increase the net output. I think this is a no-lose situation.

The AP1000’s hotel loads are about 83 MW. Presumably it needs a lot less than this in shutdown. A single NuScale unit providing 48 MW(e) ought to provide all the cooling that even a multi-GW site needs in shutdown, and you can just run some of the reactor systems on the SMR output so they never go down even if the grid does. The NuScale will run for years and is walk-away safe itself, so the site as a whole could become walk-away safe in a shutdown situation.

How long does fuel have to sit in something like an AP1000 before the passive heat losses make a meltdown impossible, assuming no coolant losses? If you’ve got an SMR capable of running the cooling systems for that long after shutdown, you’re good, no?

I agree with you, E-P, but the key is in using the NuScale plant to provide reliable, useful power, not keeping it shutdown as a “backup” unit.

It’s fine to view the output of the NuScale unit as something that can redirected if needed.

This is actually very intersting to think about.

As I don’t think there is a single reactor in the Us that has hotel load only capability or full load reject survival capability, a loss of offsite power is always a limiting issue. But with small reactors that can easily handle the load reject and stay on house loads only, you reduce the risk to the plant. Even if they apply the same tech spec requirements for SMRs as they do for big reactors like my BWR you still have quite a lot of time that you are legally allowed to stay hot on house loads. For reference in my BWR, a loss of all qualified offsite circuits gives us 24 hours to fix it, and after that 12 to shutdown (provided all of our emergency generators are operable….an SMR likely wouldn’t have emergency generators, and may only requrie 1 offsite circuit, but i digress).

Either way, the fact that the reactor can keep itself safe during LOOP conditions is a benefit in my opinion.

As for time to be safe, it depends on the plant. My understanding is that the nuScale design is easily compliant with the 7 days w/no active cooling, and depending on the fault that got you there, may be safe for weeks on passive cooling due.

NuScale issued a press release several months ago claiming a trademarked capability that it calls “Triple Crown for nuclear plant safety.”

http://www.nuscalepower.com/triplecrown.aspx

Apply whatever skepticism you desire. Based on my experience with passive cooling in operating nuclear plants and my personal interactions with the Chief Technology Officer and several engineers on the team, I have chosen to believe the claim.

@rod: “There does not need to be a one to one ratio of operator to reactor…”

Is that true under the regulations in effect today?

Regulations are written by people and can be changed by people. The NRC has expressed its willingness to listen to the justification, review the operational and emergency response concepts, observe the operator performance on high fidelity simulators and then determine the safe manning requirements.

That is encouraging news.

Do you have an estimate for what these modules will cost?

@Jeffrey Miller

The numbers I’ve seen are a little dated, but a 12 pack was estimated at $4,000 per kilowatt capacity after reaching “Nth” of a kind. That would imply that the third 600 MWe power plant would cost about $2.5 billion.

Wow. While no where near as low as gas, $4/watt is within 25% of advanced coal. And fuel costs are less than half. Let’s hope it holds!

@Ed Leaver

IMO most announced prices for natural gas plants are for machinery that represents a small fraction of the actual infrastructure required to produce electrical power from that facility.

Rarely, if ever, does the announced price include the cost of building pipelines to deliver fuel to the facility. By not including that cost or the time required to permit and construct the pipelines, the public is flamboozled to believe that the facilities are far cheaper than they really are if you include all of the costs.

In some areas, the plant owners act as free riders and just purchase gas when it is available from an existing pipeline system. Their plan for those times when gas is in short supply or not available at all is to simply shut down and wait until it is available. Last winter in New England, natural gas plants achieved an average capacity factor of less than 30% even though there were times when the electricity market really wanted their power output and was willing to pay $200/MW-hr.

Interesting. That’s about 20% less than the current cost estimates ($5 per watt after the recent 10% cost overrun) for the two V C Summer AP-1000s being built at V C Summer. So some apparent savings from standardized mass production, but not dramatic.

What about construction times? Do you know if these estimated to be substantially less than the current rather long times for larger plants? I understand that the reactor core would be built in a factory and then delivered, but I assume all the other stuff like a containment structure and pipes and turbines and so forth would be built on site much like they are now for the larger plants? It seems to me that cutting down construction times is one key to lowering costs since multiyear projects (of any kind) almost inevitably end up costing more than planned.

In the posted article Rod says “One of the new items to me was a bullet that said that NuScale now has a “line of sight” to its first 12 power plants, each of which would include 12 NuScale power modules for a total of 144 modules.”

This short sentence seems to be all of the justification that can currently be provided to merit the Blog headline “Prospective customers lining up at NuScale”.

The article provides no mention of specific customers that have made agreements to purchase NuScale reactors or have placed orders – all we have so far is a “line of sight” assurance – which would require some elaboration-interpretation to say what it exactly means.

NRC does not currently have a SMR friendly separate path to licensing (indeed, currently we have a one size fits all approach that effectively favors large reactors). The costs to design certify and license SMRs are about the same as to license large reactors. The yearly fees to NRC to operate new SMR are identical to the fees to operate large commercial Gigawatt size reactors. NRC requirements for staff and operators are currently the same for large and small reactors. There is no regulatory adjustment or advantage in chaining many small reactors modules into a larger combined reactor from a regulatory or fees standpoint.

The economic case for SMRs, including the Nu-Scale SMR, has not yet been made.

@Robert Steinhaus

The article identifies the program – WIN – that will be responsible for the first half dozen power plants. It provides a graphic illustrating the general locations of those proposed projects. It identifies the entity that plans to own the first unit and the entity that will operate that unit. The article is not meant to serve as the PR arm of the company; it provides sufficient information for any interested reader to do some additional searching and due diligence.

It is amazing to me how some internet commenters believe that companies should be more “open” about sharing valuable commercial information with their competitors, which is what happens when they make that information available to the public.

JohnGalt, I find this comment offensive. You are challenging the ethics of Rod Adams without cause.

And I find it interesting that the moment EL is absent, “John Galt” is the new gadfly.

Supports my hypothesis that there is an agency assigning one shill per website and moving them around as they are identified.

@JohnGalt

Remember when Exxon and others were suing over a uranium cartel?

I do. Do you remember who Exxon was suing and what their contention was in the suit?

The NuScale reactor is still very much a paper reactor. The question is how and when NuScale will start the manufacturing of the reactor and how and when the first unit(s) will be deployed. I can imagine that NuScale will first build a test facility at a national lab (INL or PNL/Hanford) with one or two units that will primarily used for testing and evaluation purposes. My guess is that full scale deployment of these reactors is still five to ten years away.

@2C

NuScale has stated that it is planning to have their first station operable by 2023 – nine years from now.

You are correct that the design is today’s equivalent of a “paper” reactor and is little more than a well researched digital representative of a reactor – with growing reams of design calculations, methodology, and operational concepts.

That is the process we have in the US. We now seek to complete the design, have it fully vetted by an independent regulator and THEN order components and build the machine.

Is John Galt EL???

You mean: Who is John Galt? 😉

EL is a person that used to post on this site. I believe he is a grad student. His postings bore a resemblance to those of John Galt, but I think he was a bit more detailed than Mr. Galt. His writing was compared to an earlier poster named Bas. Perhaps both went to work for the 20th Century Motor Company.

@POA

No.

And I’ve been traveling in Canada for last three weeks. Besides that we are both writing in English (which appears to be your best working hypothesis), I see little resemblance.

I really hope that NuScale will be able to pull the project through all the technical / licensing / financing hurdles. We (the nuclear industry professionals) really need any small victory (pun intended) we can get.