Interest in Smaller Nuclear Energy Systems Continues to Heat Up – Bloomberg Businessweek Latest to Notice

On Monday, May 17, 2010, Bloomberg Businessweek published an article by Jeremy van Loon and Alex Morales titled Fridge-Sized Nuclear Reactors to Tap $135 Billion Power Market. (Update: The article headline has been changed to now read Miniature Nuclear Plants Seek Approval to Work in U.S (Update1); the link still works.)

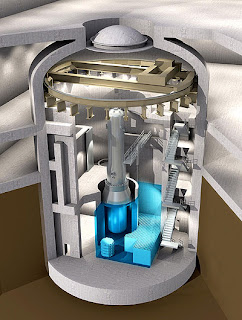

The article focuses on John Deal, CEO of Hyperion and his effort to build sealed units that can operate in remote locations for 5-8 years before needing to have the core replaced with a fresh load of fuel. However, it also describes Toshiba’s 4S (Super-Safe, Small, Simple) project, which may first be implemented in Galena, Alaska (Note: Until I inserted that link, I had forgotten that it has been more than 5 years since I first wrote about that project. According to Bloomberg Businessweek, the company might be submitting its license application later this year.)

The article mentions in passing that there are at least six projects making progress in the area and lists NuScale, Rosatom and Westinghouse. There is a subject mentioned in the article – twice – that should have raised questions on the part of the reporters, but does not seem to have done so.

Certifying and building small reactors will require the same multi-year licensing procedure necessary for bigger plants. And since no small-scale systems are operating, there’s no track record to know how well they will work.

Then, just a couple of paragraphs later:

So far, no manufacturer has sought certification for any small reactor, according to the U.S. Nuclear Regulatory Commission. Formal approvals would probably take three to five years, the same as for bigger reactors, said Scott Burnell, a spokesman for the commission.

Small reactors have been used in U.S. submarines since the USS Nautilus was commissioned in 1954. Russia’s Rosatom Corp. is using its experience on submarines and icebreakers to develop atomic plants for floating barges.

The first question that I would have asked if reporting this story is “Why should it take as long to certify a small system with fewer components as a large, complex system?” Aren’t the required reviews based on investigating the pieces and parts, operating assumptions, procedures and understanding how they all fit together? It would seem logical that less stuff would require less review. A follow on to that question would be – does a small reactor manufacturer have to go through the NRC or are there more rapid review systems available in other parts of the world where the reactors might be useful?

The second topic that begs a question is the statement that there are no small-scale systems operating when there is also a paragraph stating that small reactors have been used in U. S. submarines and icebreakers for more than 50 years. Huh?

After reading the article, I sent a note to the author thanking him for covering the topic and mentioning that he left out a few interesting projects like B&W’s mPowerTM. Oh well, I guess you cannot expect complete coverage of a complex topic in such a short article.

If you are interested in small reactors on a professional basis, do not forget to mark your calendars and register for the Platts sponsored Small Modular Reactor meeting being held in Washington, DC on June 28 and 29.

Update: (Posted May 18, 2010 at 1:23 am) Bloomberg Businessweek has updated their article with data from the IAEA about energy demand growth and also changed the headline to Miniature Nuclear Plants Seek Approval to Work in U.S (Update1)

“The first question that I would have asked if reporting this story is ‘Why should it take as long to certify a small system with fewer components as a large, complex system?’ Aren’t the required reviews based on investigating the pieces and parts, operating assumptions, procedures and understanding how they all fit together? It would seem logical that less stuff would require less review.”

The “three to five years” is the speed of bureaucracy. Technical considerations are only a second-order effect. 😉

You work for a large organization, Rod, so you should be familiar with this. Much like their physical analogues, projects in a bureaucracy are limited by a terminal velocity that is inversely dependent on the viscosity — no matter how hard you push, the damn thing doesn’t move any faster. Organizations within the US Government tend to be highly viscous.

Besides, this is a problem from Management 101. It’s not as if there’s only one engineer doing all of the work.

If I have to review 20 systems, I hire 20 teams. If I have to review 5 systems, I hire 5 teams. Nevertheless, I don’t expect the each team to finish a complete and thorough review any sooner simply because there are fewer teams. The extra complexity is only additional work for the systems engineers who have to study the entire plant as a whole. Nevertheless, their work is a very small subset of the entire amount of work that needs to be done to certify a design.

In a properly functioning organization, a less complex system will require less resources to review, but that does not necessarily mean that it will take less calendar time.

If engineers in 1960 took, I don’t know, 12-24 months to do a “complete and thorough review” of a new reactor concept, shouldn’t they be faster in 2010, not slower? After all, our level of knowledge is higher, and the tools used more powerful, is it not? I realize that the political reality has changed from 1960 to 1990, but the political reality has also changed from 1990 to 2010; the pendulum swings back in the other direction now.

Aren’t there certain inherent strengths in terms of safety for smaller reactors with lower total system energies than with large reactors with correspondingly large total energies? Shouldn’t these inherent strengths dictate the scale and the detail of the regulatory analysis conducted?

Sometimes, I do wonder if this highly viscous fluid of which you speak is miscible with common sense, so as to to raise its Reynolds number from the extraordinarily low value that it is today…or perhaps it can be heated up, say by lighting a political fire under it (such as a fire caused by oil floating on water), so that it flows a bit more freely and is less dense and obstructive to forward motion.

@Dave – smaller systems do not only have lower total system energies, but they also have far lower source terms, less decay heat per unit of heat removal surface area and less complex sensing and control systems.

Besides – for those systems that are simply evolutionary light water designs that use fuel forms that are almost identical to those in use today – with the exception that they use shorter elements – it seems that there should be some ways to reduce the review times by at least a bit. Failing any reduction for the first of a kind, there should be a clear path established that uses some of the same principles that have been successfully applied to license extensions.

The thing that frustrates me is that we have so many reasons to want to enable the expansion of nuclear energy, but we cannot seem to figure out how to reduce the barriers that have been erected over the years.

“If engineers in 1960 took, I don’t know, 12-24 months to do a ‘complete and thorough review’ of a new reactor concept, shouldn’t they be faster in 2010, not slower? After all, our level of knowledge is higher, and the tools used more powerful, is it not?”

Well, sure, if you want to go back to designing reactors with a slide rule, then yeah, you can review a design in 12 months. The trick is that there’s so much margin built into the design, there’s not much to check. That’s the advantage that comes with building something three times as sturdy as it needs to be. Your calculations don’t have to be very precise.

This is also why the reactors built in that era were small, inefficient, and frankly, didn’t run very well. They also typically didn’t run very long before they were retired.

We’ve learned a lot since then, which is why the designs today are so much better. We also have better, more sophisticated tools; however, that sophistication comes with a price. It also means that these tools are more complicated to check properly.

Different scale designs have different strategies for safety, so the naive assumption that smaller means simpler (or simpler to check) does not necessarily hold up. Often, a particular strategy seems attractive because it greatly simplifies part of the design relative to other strategies, but in fact, it has simply moved the complexity to another part of the design.

To take an example from my experience, one advantage that High-Temperature Gas-Cooled Reactors have is their greatly simplified safety systems (in fact, a safety system with no moving parts). This simplification also means, however, that the fuel itself has essentially become the primary safety system. Thus, fuel performance becomes extremely important, and fuel qualification becomes far more complicated.

I’ve thought about what would simplify the licensing process the most for an LWR, and I’m betting that it would be a very simple and robust ECCS, one that has near zero moving parts. At least, in my admittedly highly unexpert opinion, the design of the ESBWR’s safety systems really are revolutionary from that angle, in that there’s practically nothing that can go wrong if the last set of safety systems are activated.

E.g. if all else fails, and uncovery occurs or is imminent, depressurize the primary system into into the drywell volume (drywell = BWR containment) using redundant explosive valves on the top of the RPV, flood the drywell volume by firing a second set of explosive valves which are connected to pipes that are in turn connected to large water tanks within the drywell, but above the core, that turn the drywell into a lake – a lake with a water level above TAF in the RPV – using a large amount of water stored above the containment for that purpose. Once the RPV finishes blowing down, a third set of explosive valves – at the bottom of the RPV – are activated – so as to take water in and establish a convective flow within it. GE’s set it up so that their SLCS – which is an emergency boron injection system – the PWR equivalent being accumulators filled with borated coolant – also automatically injects if the final safety system is activated, but I figure that you could even pre-borate the containment flood water so as to kill any ATWS events and remove a separate system which might add cost and complexity to a small modular reactor.

The only problem I could foresee would be pressure management of the containment, due to the steam evolved, but this can be dealt with using either active or passive systems. You could use something along the lines of the ESBWR’s passive containment cooling system, which is, basically, build a bunch of pipes into the ceiling of the drywell, to carry off the evolved steam, from the drywell, run the pipes through water tanks outside the drywell, so as to condense the steam within, and then have the condensate fall back into the drywell “lake” as “rain”. All you have to do to keep the drywell from overpressurizing is to periodicly replenish the water in the PCCS tanks until the fuel has cooled enough that you can unseal the drywell and begin defueling the reactor.

You can’t really argue with something as simple as that. How can the NRC go about delaying such a reactor? It’s so simple, and nearly foolproof. All that has to work is 3 explosive valves systems, with one out of the 4 valves being requred to work for system success.

Further, I’ve been able to tell that NuScale has a similar system, from their published literature (though they have a very small “containment”, such as it is) – and I suspect the mPower has one based on their illustrations – the large water pool above the containment makes me suspect something similar is going on. (B

A visous cycle is just the thing Rod. A hydraulic combined cycle turbine to put under the hood of my car. A nuclear turbine scaled to human needs. Unfortunately, the viscousity we now contend with is all over the Gulf of Mexico….albeit government was very fluid in granting permits. What is the viscousity of this cozy relationship?

I don’t think taking ~3 years for the review of a new plant design is unreasonable, or is a real problem. The real problem is the undue licensing burden for follow-on, carbon copies of a given reactor design, large or small.

With the larger reactors now in licensing, the real truth is that the Final Design Approval (FDA) didn’t mean nearly as much as one might have thought. Most of the detailed design remained to be done, and it is being done in the first (“reference”) COL applications for each plant design. This is why they’re taking 3 years or so. I don’t have a problem with that.

What I do have a problem with is that NRC says it needs 2-3 years to license reactors of the same design, after the initial reactor (R-COL application) has been approved. I cannot fathom why NRC would need 2-3 years to license a reactor that is a carbon copy of fully designed and already approved reactor. Given that bounding values for environmental parameters (e.g., seismic G-loads) are used in the analyses for the generic design, site specific issues are just not that significant. A helpful policy would be for Congress, etc.., to simply instruct NRC that it has no more than one year to approve S-COL applications (for follow-on copies).

With respect to small, factory-produced reactors, again, taking several years to do a thorough review of the design is not a problem. However, once a design is licensed, I would go even further than I would for large reactors with respect to limiting the licensing review for copies of the reactor. The way it works in the spent fuel dry storage cask business (where I’ve worked) is that you get a license for a design, not each cask you build. Once the license is granted, you can produce as many as you want, without further licensing. NRC”s only involvement is that they periodically do QA inspections of the facilities building the casks.

It simply MUST work this way for small reactors. The design is licensed, not the individual unit. Once the license is granted, the reactor factory can pump out as many as it wants with no further license applications. NRC will probably have full-time resident inspectors at the reactor fabrication plant(s), and that’s fine. One compromise that will probably have to be made is that there will have to be some analyses of each new site where one or more reactors are to be used. The battle will be to make that site evaluation (and licensing) as limited as possible. It certainly shouldn’t be any more detailed than that which is required for a fossil unit of similar size (e.g., gas). One thing that must happen, at a minimum, is that if a utility qualifies a site for generation with the small reactor design, it can add units to the site at will with no further licensing.

Jim – Thanks to the Westinghouse Off-shore power systems project, there is a section of the 10 CFR Part 52 called Subpart F – Manufacturing Licenses. http://www.nrc.gov/reading-rm/doc-collections/cfr/part052/

The scope of this section is as follows:

52.131 – “This subpart sets out the requirements and procedures applicable to Commission issuance of a license authorizing manufacture of nuclear power reactors to be installed at sites not identified in the manufacturing license application.”

It is a very interesting option for building standard plants. Here is how long they can last:

52.173 – “A manufacturing license issued under this subpart may be valid for not less than 5, nor more than 15 years from the date of issuance. A holder of a manufacturing license may not initiate the manufacture of a reactor less than 3 years before the expiration of the license even though a timely application for renewal has been docketed with the NRC. Upon expiration of the manufacturing license, the manufacture of any uncompleted reactors must cease unless a timely application for renewal has been docketed with the NRC.”

There will need to be site licenses

52.167(c)(1) – “A holder of a manufacturing license may not transport or allow to be removed from the place of manufacture the manufactured reactor except to the site of a licensee with either a construction permit under part 50 of this chapter or a combined license under subpart C of this part. The construction permit or combined license must authorize the construction of a nuclear power facility using the manufactured reactor(s).”